Gear-shifting mechanism for manual transmission

A technology of manual transmission and gear shifting mechanism, which is applied in the direction of mechanical equipment, components with teeth, transmission device control, etc. It can solve the problems of driving comfort and shifting comfort, gear disengagement, and vehicle safety cannot be guaranteed, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

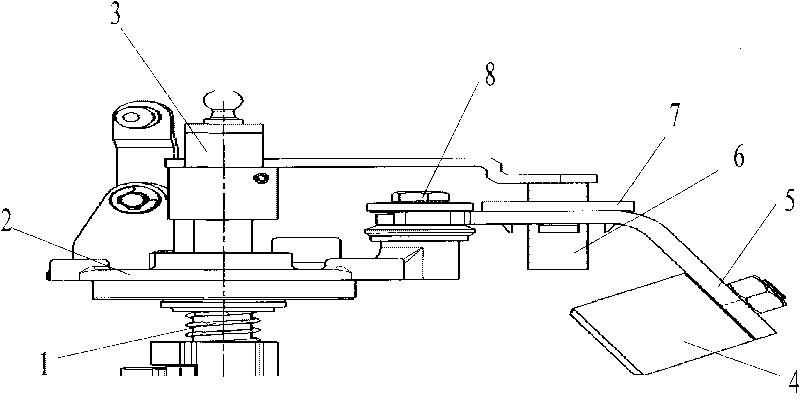

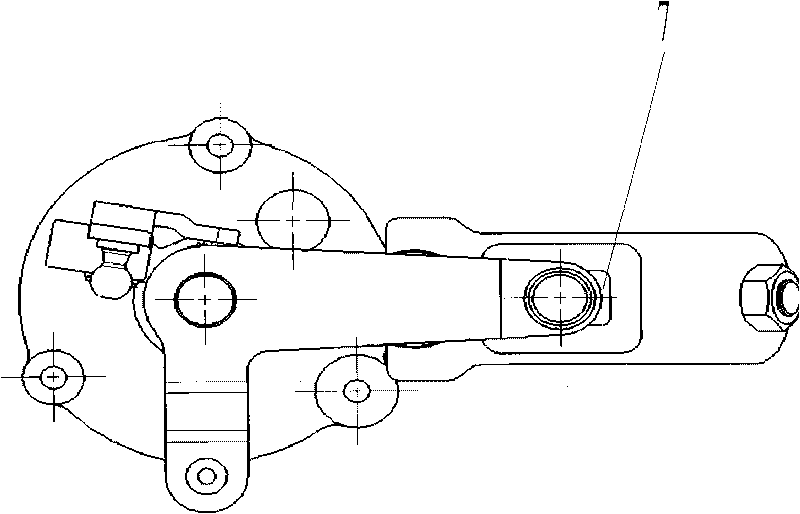

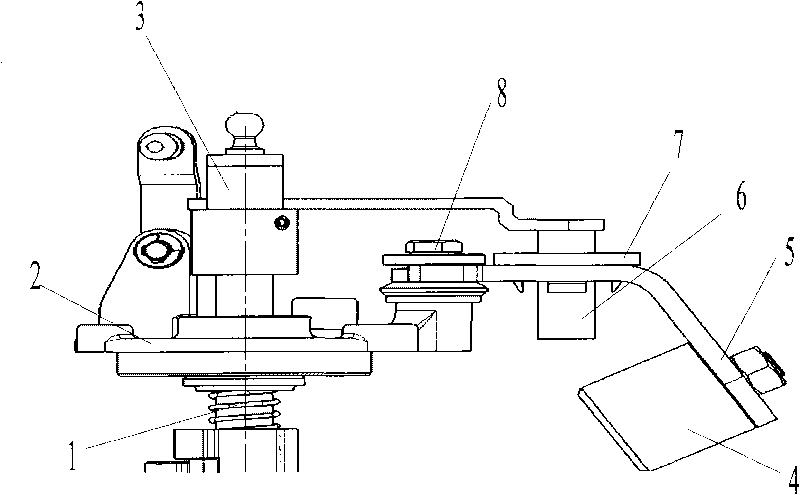

[0019] The invention provides a shift mechanism of a manual transmission, which can effectively block the transmission of the vibration of the balance weight to the shift handle.

[0020] The basic idea of the present invention to solve the above-mentioned technical problems is: in the shifting mechanism of the automobile transmission, there is a counterweight connecting plate that can freely rotate around a shift shaft connected with the transmission casing, and the counterweight connecting plate It can be driven to rotate around the rotating strut bolt by the rotation of the counterweight toggle pin. The toggle pin of the counterweight is connected with the shift shaft of the shifting mechanism, and the counterweight is connected to the shift box through the bolts of the rotating pillar, and the bolts press the opening of the connecting plate of the counterweight to make the gears pressed by the bolts The counterweight and its connecting plate rotate freely around the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com