Novel automobile exhaust system hanging block

A technology of automobile exhaust system and hanging block, which is applied to vehicle components, gas intake of power plant, power plant, etc. Insufficient bits, etc., to achieve good NVH performance, improve durability, and reduce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, the specific implementation of the present invention will be further described in detail through the description of the embodiments with reference to the accompanying drawings.

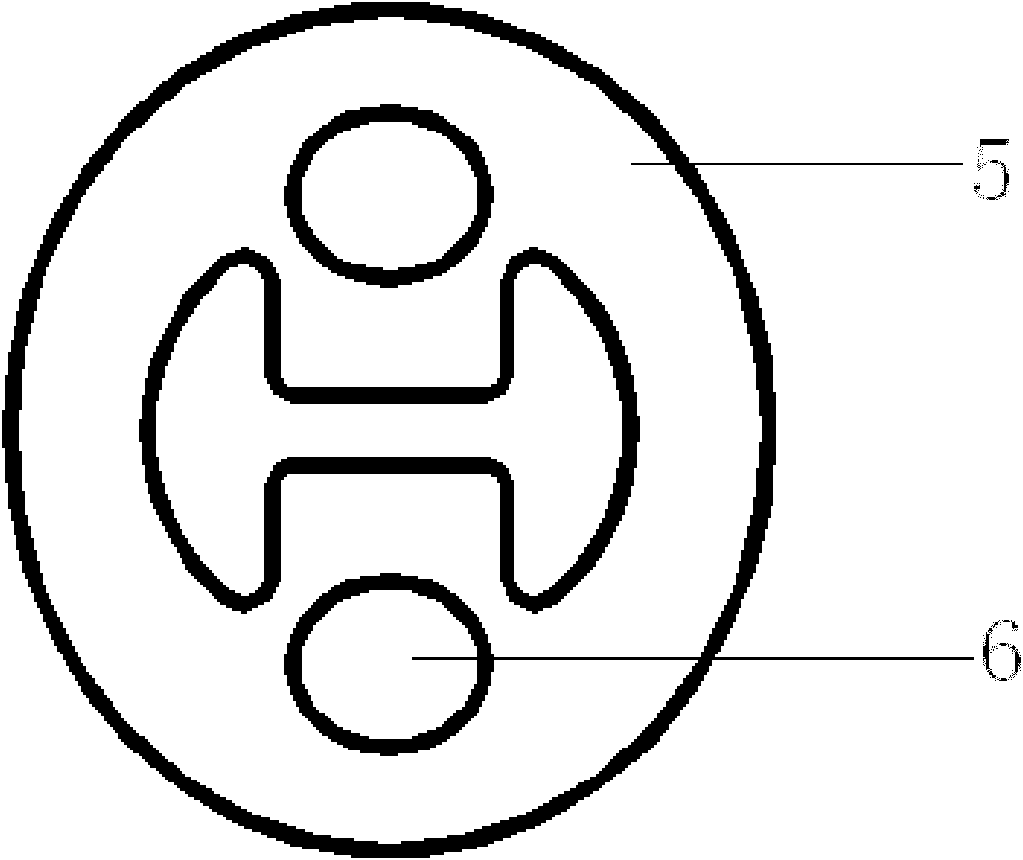

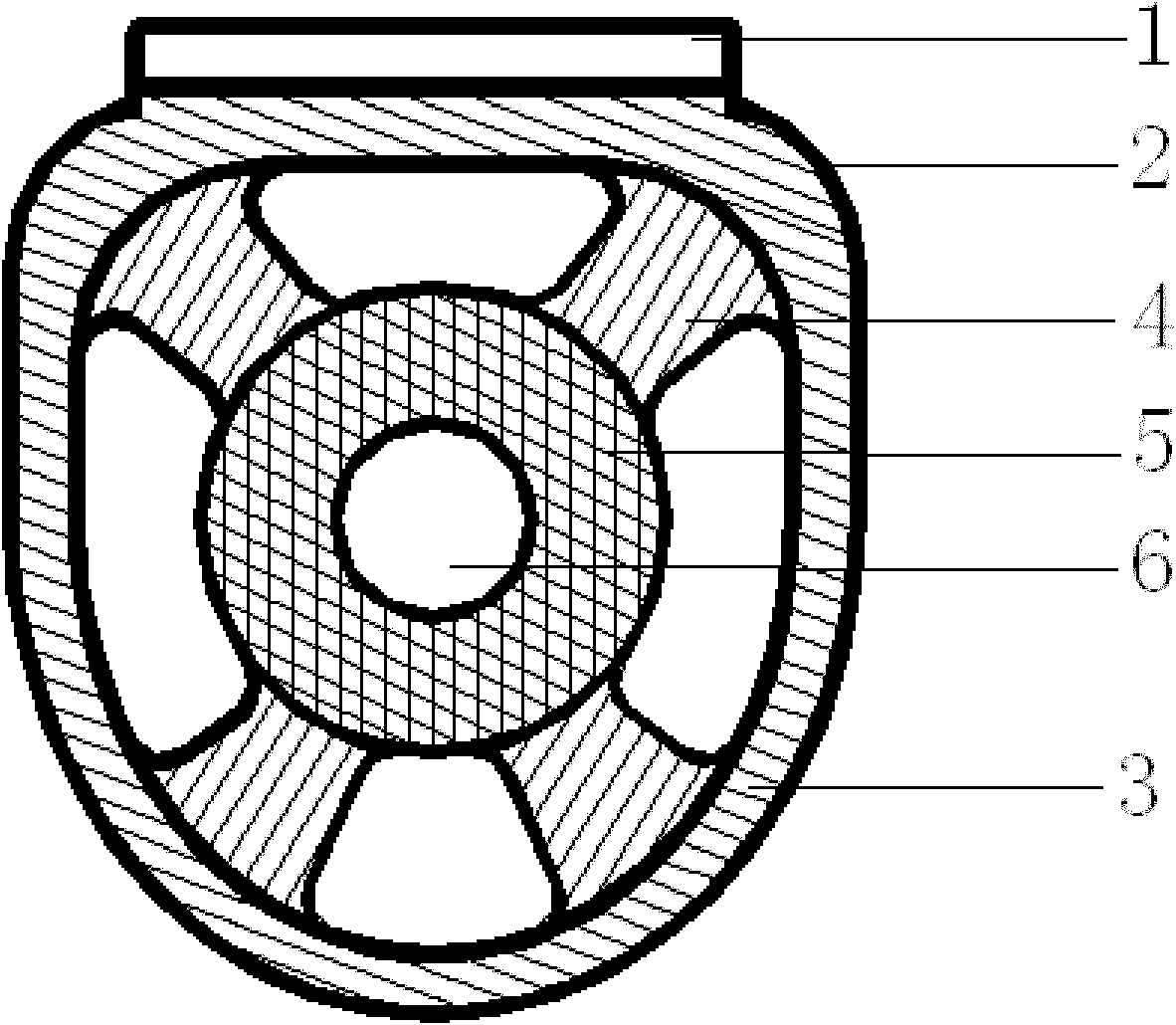

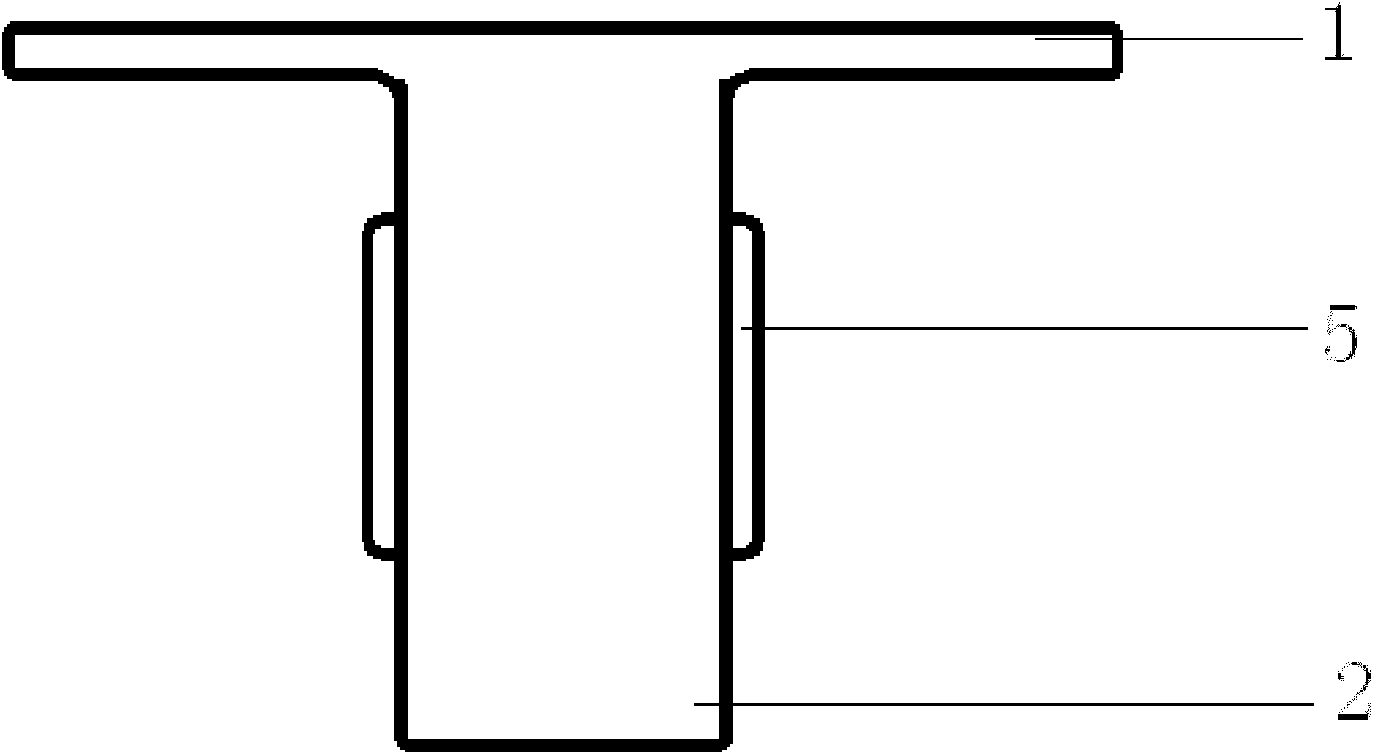

[0022] Such as figure 2 , image 3 , Figure 4 with Figure 5 As shown, the present invention is a new type of car exhaust system hanging block. The exhaust pipe of the car exhaust system is supported by the hanging block and connected to the car body. The exhaust system hanging block includes a metal bracket 1 connected to the car body. 1. The metal frame 2 welded to the metal bracket 1 and the exhaust pipe installation part; the metal frame 2 is located around the outside of the exhaust pipe installation part, and the exhaust pipe installation part is fixedly connected to the metal frame 2 through a plurality of rubber reinforcement ribs 4; A vulcanized rubber body 3 is wrapped inside the metal frame 2 and connected to it as a whole through vulcanization. Four rubber reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com