Self-returning offshore jacket platform and manufacturing method thereof

A technology for offshore platforms and jackets, which is applied in construction, artificial islands, and infrastructure engineering. It can solve the problems of seldom considering the reset function of the structure, the effect of the structure's anti-vibration effect, and the structure cannot be reset, so as to increase the difficulty of construction, Improved robustness and reset function, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Such as Figure 17a As shown, the connection point of the prestressed external steel tie rod 7 at the connection platform 2 is single.

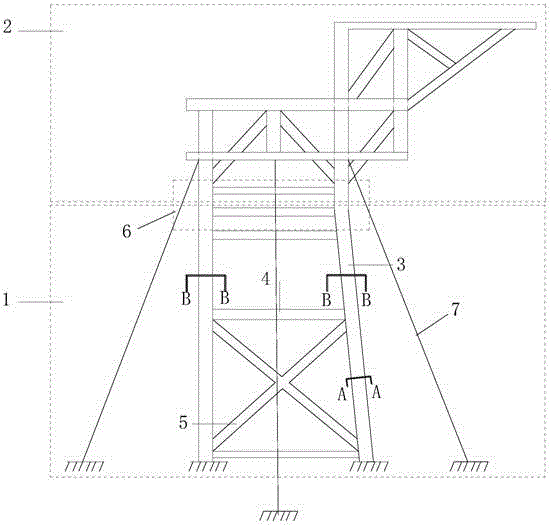

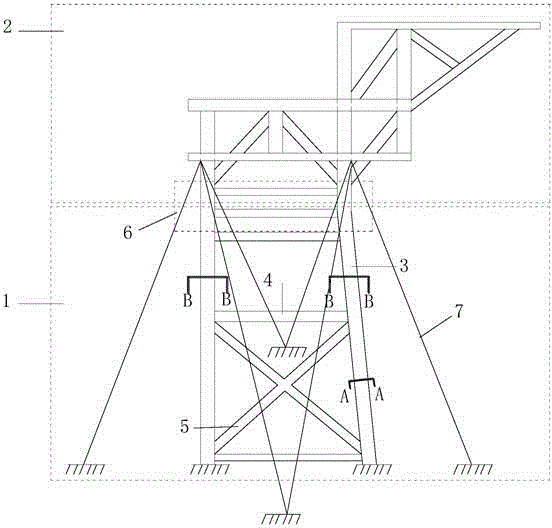

[0071] This embodiment consists of two parts. As shown in FIG. 1 , an ocean platform frame 1 and an ocean platform 2 are connected. The offshore platform frame 1 mainly includes an offshore platform conduit 3 , an offshore platform cross brace 4 , an offshore platform diagonal brace 5 and a prestressed external steel tie rod 7 .

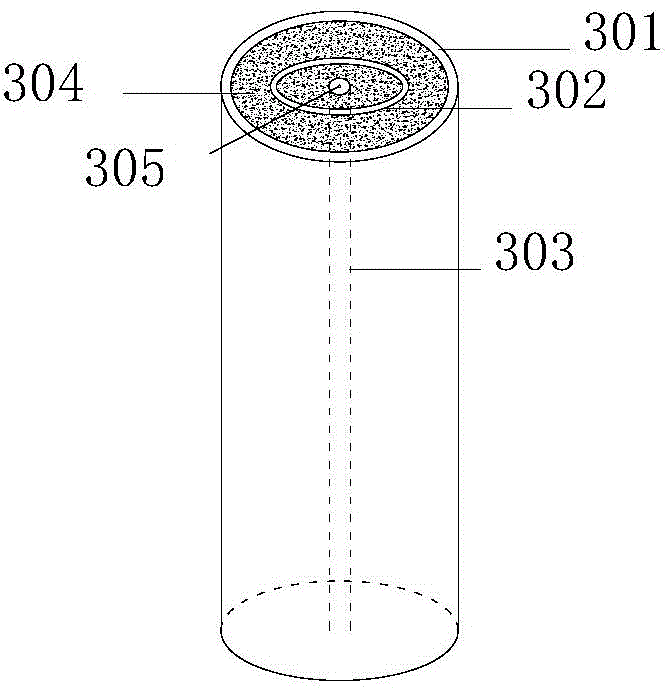

[0072] The offshore platform conduit 3, such as Figure 2-10 As shown, the inner steel pipe is placed inside the outer steel pipe and is coaxial with the outer steel pipe 301. The interlayer between the inner steel pipe 302 and the outer steel pipe 301 is filled with interlayer concrete 304 . The positions of the inner and outer steel pipes are mainly ensured to be coaxial through the positioning pegs 306 welded on the outer steel pipe 301 . In order to ensure that the offshore platform can become a struc...

Embodiment 2

[0085] Such as Figure 17b As shown, the connection points of the prestressed external steel tie rods 7 at the connection platform 2 are double. This embodiment is the same as implementation 1 and is made up of two parts, the ocean platform frame 1 and the ocean platform 2 are connected to form. The offshore platform frame 1 mainly includes an offshore platform conduit 3 , an offshore platform cross brace 4 and an offshore platform diagonal brace 5 .

[0086] The offshore platform conduit 3 described in Embodiment 2, such as Figures 12 to 15 As shown, it is basically similar to the offshore platform conduit of Scheme 1. The difference is that the variable-diameter inner steel pipe 3010 of the conduit in the offshore platform frame 1 begins to change section at the junction of the outer steel rod 301 and the offshore platform 2, and the diameter of the steel pipe is appropriately reduced to facilitate the insertion of the inner steel pipe 302 of the platform 2. The length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com