Pipeline support with built-in comb-shaped anti-vibration pad

A technology of pipeline support and vibration damping pad, which is applied in the direction of pipeline protection, pipeline protection through heat insulation, pipe components, etc., can solve the problems of poor economy, achieve good versatility, improve vibration reduction, and increase flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

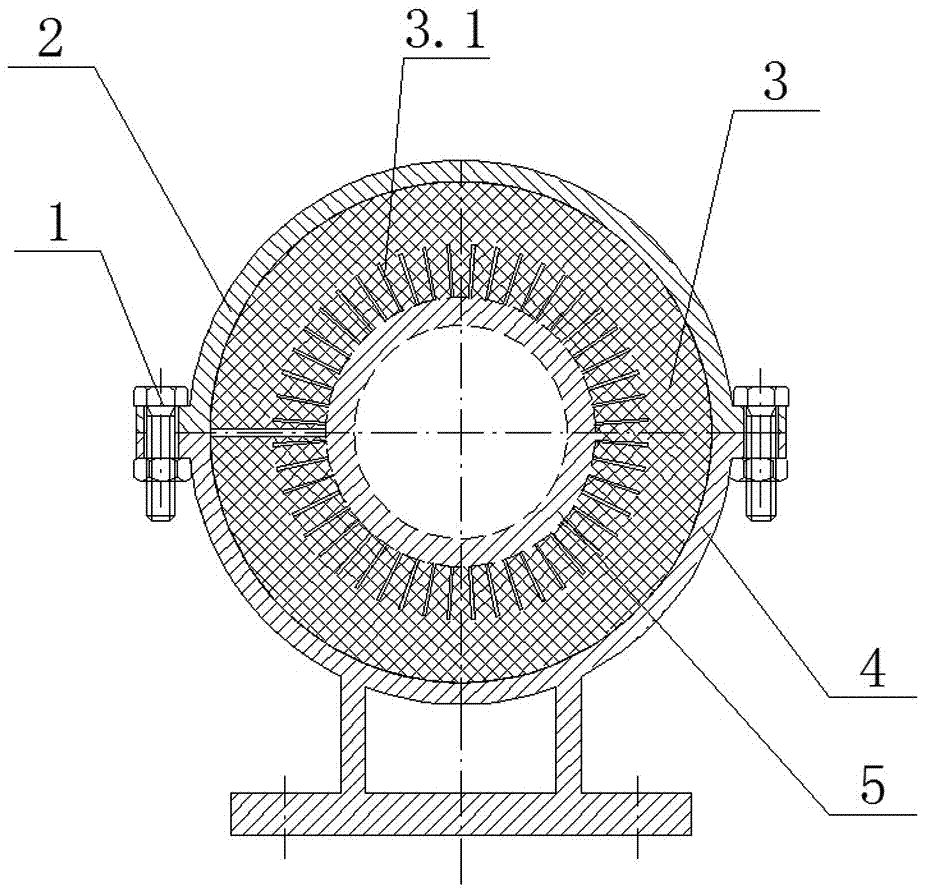

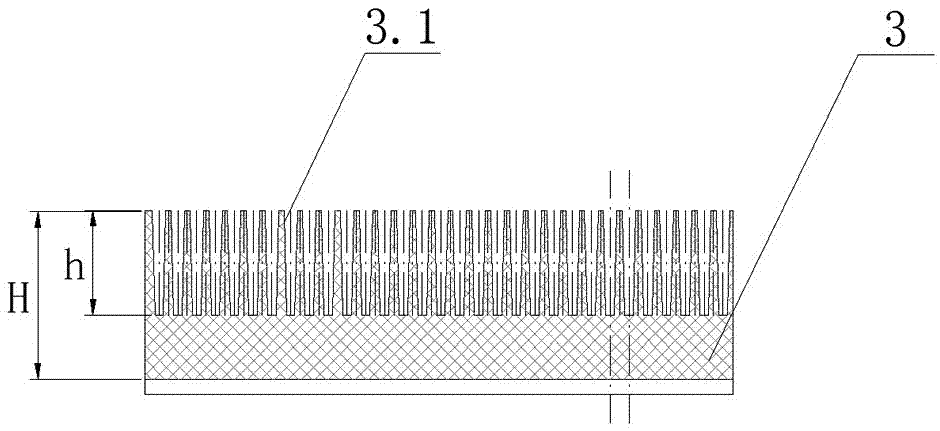

[0019] figure 1 The pipeline bracket lined with comb-shaped damping pads shown includes bolts 1 , pipe clips 2 , vibration damping pads 3 and bracket seats 4 . The support base 4 belongs to the frame member, the upper part of which is an open semicircular ring facing upwards, the lower part is provided with flat feet for fixed connection, and the open ends of the semicircular ring are provided with vertical through holes on the ears protruding outwards. . The pipe clip 2 is a supporting part of the support seat 4, and it is only a semicircular ring with protruding ears at both ends. The pipe clip 2 and the support seat 4 are paired to form a circular clip, which is used for The bolts 1 are connected as a whole. In order to achieve the axial positioning of the circular clip and the damping pad 3 of the inner liner, an annular boss is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com