Servo type vertical shock absorber and application structure and shock absorption method of servo type vertical shock absorber

A kind of application structure and servo-type technology, applied in the direction of shock absorber, inertia effect shock absorber, spring/shock absorber design characteristics, etc., can solve the problems of lack of active control and low vibration damping effect, and achieve significant reduction vibration effect, controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

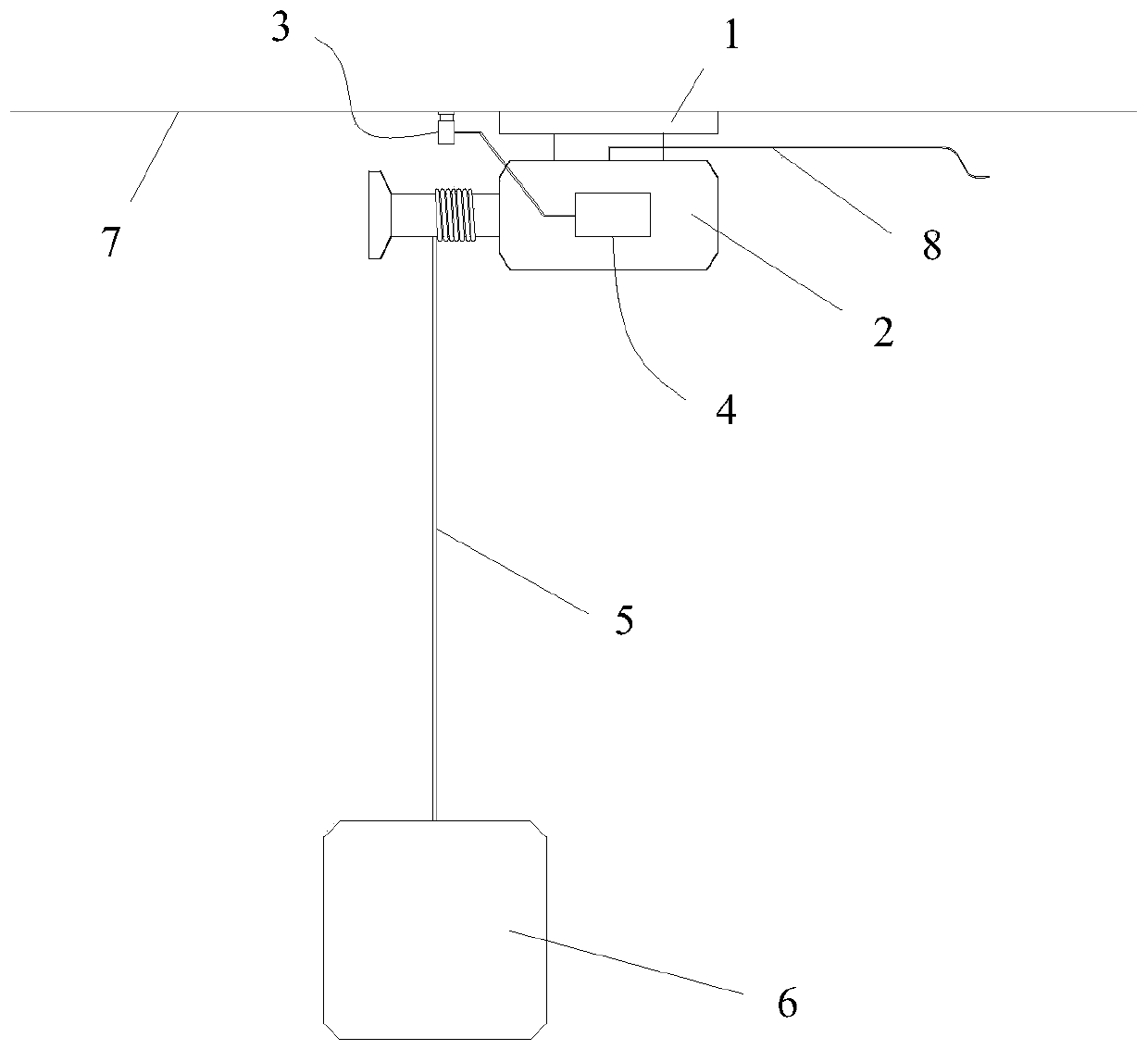

[0065] See attached figure 1 , the embodiment of the present invention discloses a servo-type vertical shock absorber, including: a motor base plate 1, a servo motor 2, an acceleration sensor 3, a servo system 4, a traction mechanism 5 and a mass block 6;

[0066] The top surface of the motor bottom plate seat 1 is fixedly connected with the vibrating surface 7;

[0067] The servo motor 2 is fixed on the bottom surface of the motor base 1;

[0068] The sensing end of the acceleration sensor 3 is fixed on the vibration surface 7, and is used to collect the vertical vibration acceleration value of the vibration surface 7;

[0069] The servo system 4 is electrically connected to the servo motor 2 and the acceleration sensor 3 respectively;

[0070] The input end of the traction mechanism 5 is connected to the power output shaft of the servo motor 4, and can output the rotational motion of the servo motor 2 as repeated linear motion in the vertical direction;

[0071] The mass ...

Embodiment 2

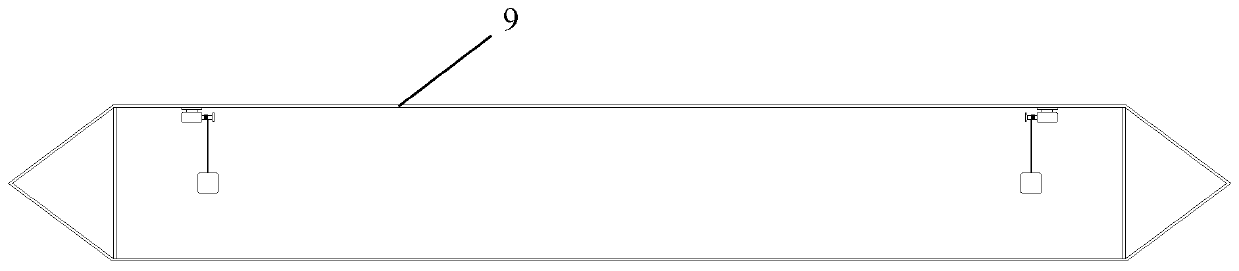

[0076] Participate in figure 2 , the embodiment of the present invention discloses an application structure of a servo-type vertical shock absorber. The servo-type vertical shock absorber provided in Embodiment 1 is installed on the box-shaped bridge 9 of a suspension bridge or a cable-stayed bridge, and the motor base The top surface of the plate 1 is fixedly connected with the inner top surface of the box-shaped bridge 9 , that is, the servo-type vertical shock absorber is installed inside the box-shaped bridge 9 .

Embodiment 3

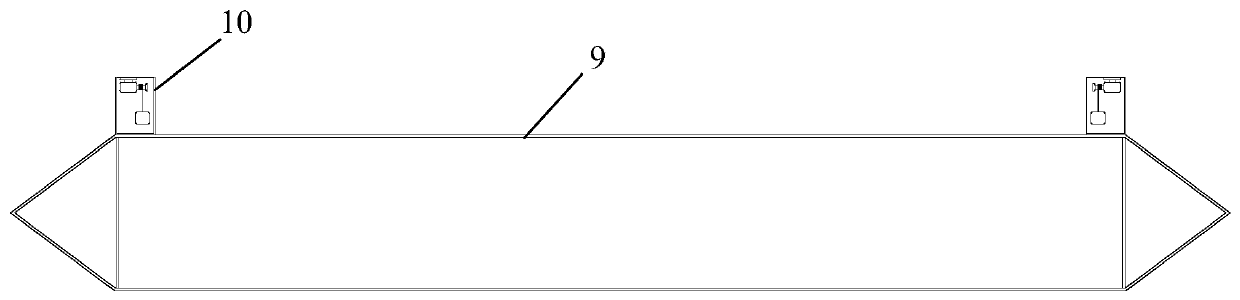

[0078] See attached image 3 , the embodiment of the present invention discloses an application structure of a servo-type vertical shock absorber. The servo-type vertical shock absorber provided in Embodiment 1 is installed on a box-shaped bridge 9 of a suspension bridge or a cable-stayed bridge. The box-shaped The outer top surface of the bridge 9 is fixed with a steel frame 10, and the top surface of the motor base plate 1 is fixedly connected with the inner top surface of the steel frame 10, that is, the servo vertical shock absorber is installed outside the box bridge 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com