Anti-pulling embedded-type gate-type steel frame steel-joint column foot and construction method thereof

A portal rigid frame and construction method technology, which is applied in basic structure engineering, architecture, building construction and other directions, can solve the problems of difficult installation of portal rigid frame, high requirements for the burying accuracy of anchor bolts, and large size of short foundation columns. , to achieve the effect of simple construction, saving steel and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

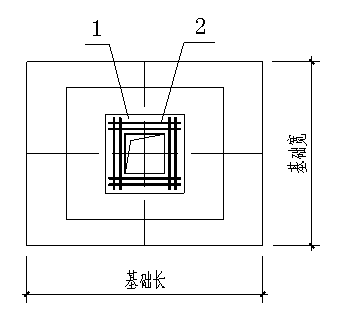

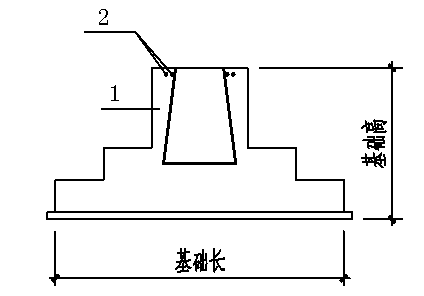

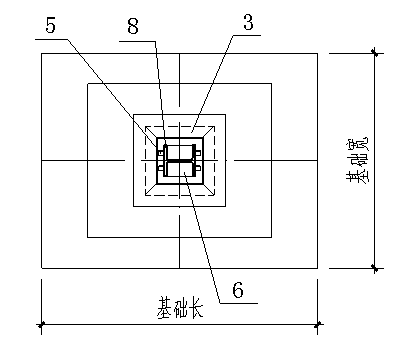

[0014] The embodiment of the present invention: the pull-resistant embedded portal rigid frame rigid connection column base of the present invention adopts the following technical scheme: the basic short column 1 is composed of cast concrete, and the local compression-proof steel mesh is arranged on the top of the basic short column 1 2. Set the foundation reverse cup hole 3 in the foundation short column 1, insert the lower section of the steel column 8 into the foundation reverse cup hole 3, and weld the steel column bottom plate 4 at the bottom of the steel column 8 at the height of the lower section of the steel column 8. Weld the steel column studs 5 within the scope, 100mm down from the top of the foundation short column 1, and weld the horizontal stiffening plate 6 to the lower section of the steel column 8; the foundation short column 1 is poured into the foundation reverse cup hole 3 by pouring cement mortar 7 and Steel column 8 is combined.

[0015] The construction met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com