Corrugated plate steel mold integrated composite structure bridge deck system and construction technology thereof

A steel mold integrated and combined structure technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve problems such as poor combination, poor force transmission performance of the bridge deck, hidden safety hazards, etc., and achieve the goal of solving poor combination and good bending resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

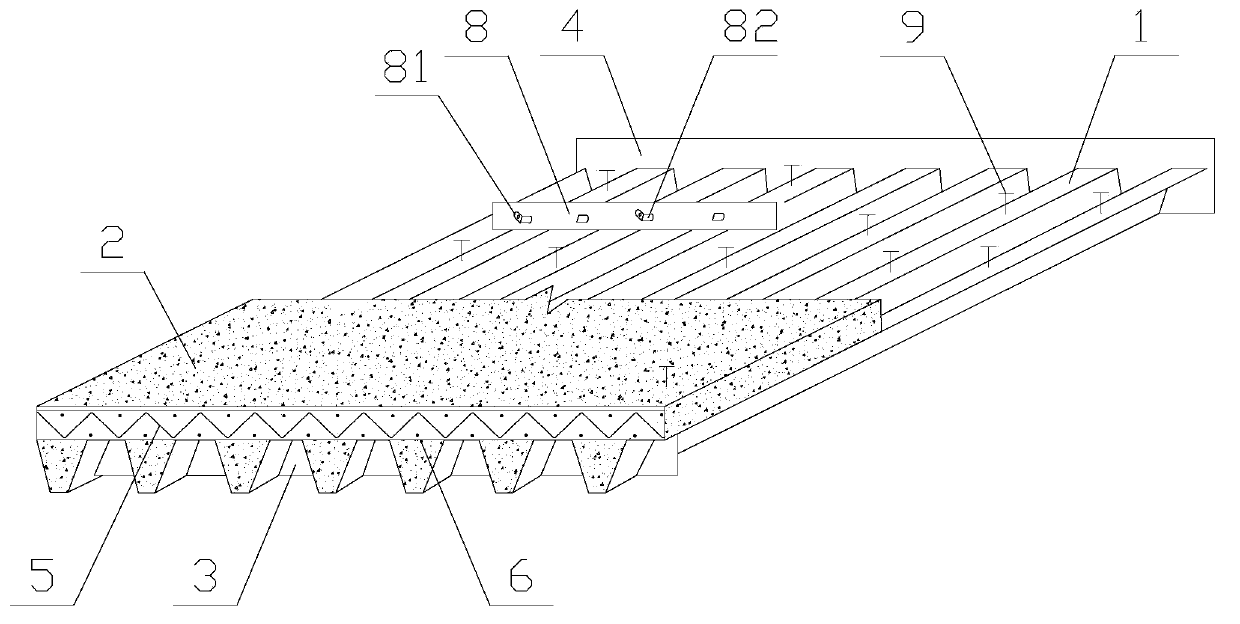

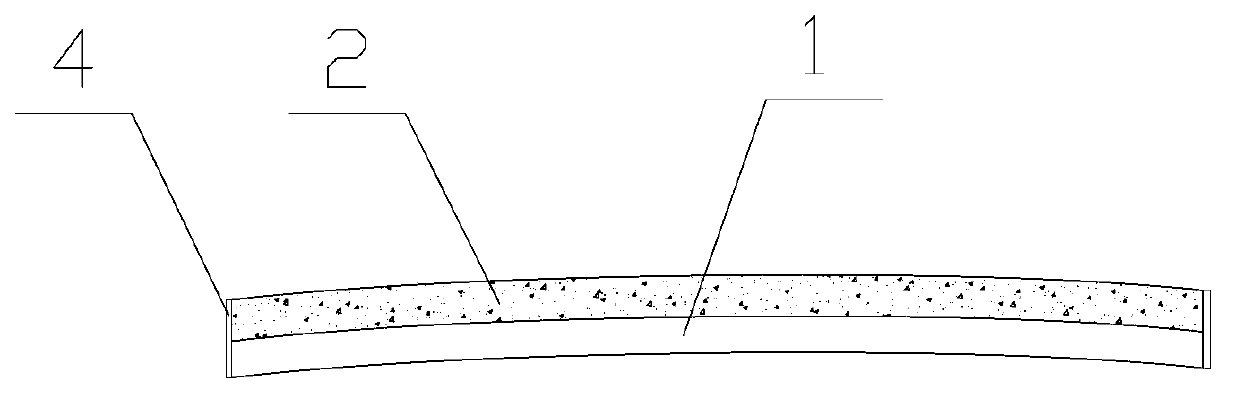

[0026] Corrugated plate steel mold integrated structure bridge deck system, such as Figure 1 to Figure 2 As shown, it includes a corrugated steel bar 1, a curved steel bar 5, a straight steel bar 6 and concrete 2, the curved steel bar 5 is connected with the straight steel bar 6, the straight steel bar 6 is connected with the corrugated steel bar 1, and the concrete 2 is poured on the corrugated steel bar 1 upper part. The corrugated steel plate is not only used as a steel-concrete composite structure of the bridge deck, but also as a bridge deck concrete formwork. At the same time, the wave troughs of the corrugated steel plate form multiple rib beams, which have good bending resistance, especially the curved force-transmitting steel bars are arranged on the corrugated plate. , to solve the poor combination of the bridge deck system.

[0027] The connection key is welded on the corrugated steel plate 1, and the connection key is one or more combinations of steel bars, pegs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com