Oil cylinder and connecting rod drive system for compounded transmission hydraulic machine

A technology of connecting rod drive and hydraulic press, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of difficult pressure control, poor process adaptability, and low production efficiency, and achieve reduced installed capacity, compact structure, and overcome eccentric loads Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

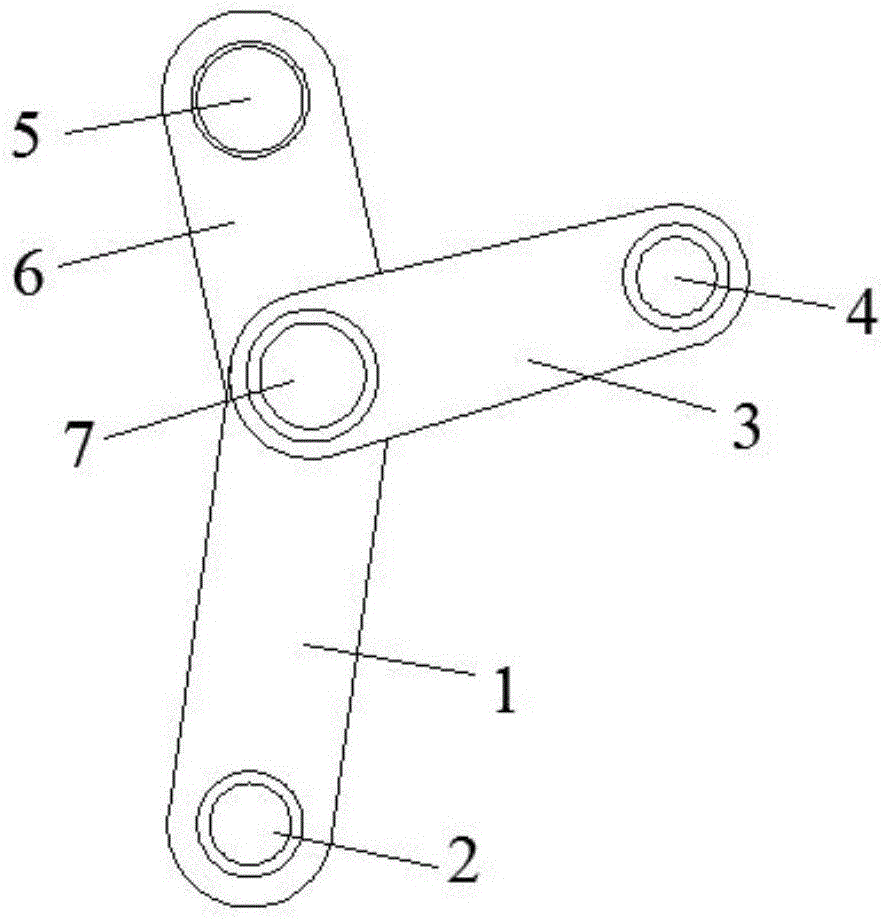

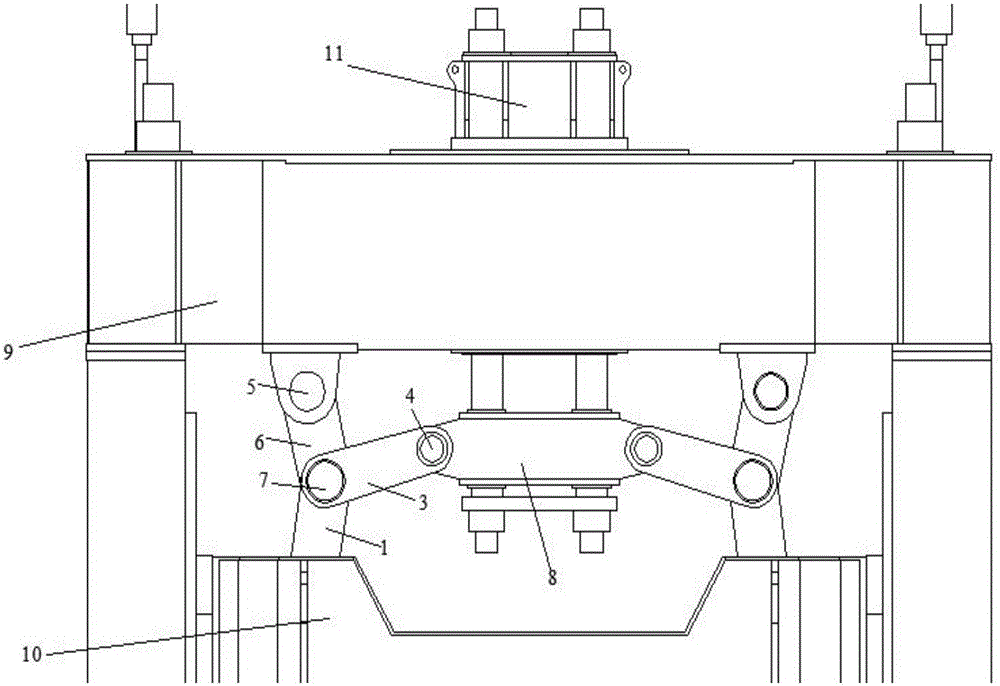

[0017] A cylinder-connecting rod drive system for a compound transmission hydraulic press, such as Figure 1-2 As shown, it includes a symmetrical connecting rod booster mechanism and a hydraulic cylinder, wherein the symmetrical connecting rod booster mechanism is composed of two groups of four symmetrical connecting rod mechanisms, and each group of connecting rod mechanisms consists of toggle lever 6, toggle pin 5, output Rod 1, output pin 2, driving rod 3, driving pin 4, and hinge pin 7. The toggle lever 6 is connected to the upper beam 9 of the hydraulic press through the toggle pin 5, and the driving rod 3 is connected to the small sliding seat 8 of the hydraulic press through the driving pin 4. The rod 1 is connected to the slider 10 of the hydraulic machine through the output pin 2, and the toggle lever 6, the driving rod 3 and the output rod 1 are connected through the hinge pin 7; the movement of the oil cylinder 11 of the hydraulic machine drives the slider 10 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com