Embedded steel-encased high-intensity concrete combined beam with toggle pins

A technology of high-strength concrete and outsourcing steel, which is applied to structural elements, building components, and elongated structural components for load-bearing, etc., can solve the problems of reducing component ductility, increasing seismic action, and increasing cross-sectional size, etc., to achieve reduction The process of setting up formwork, reducing the use of formwork, and improving the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

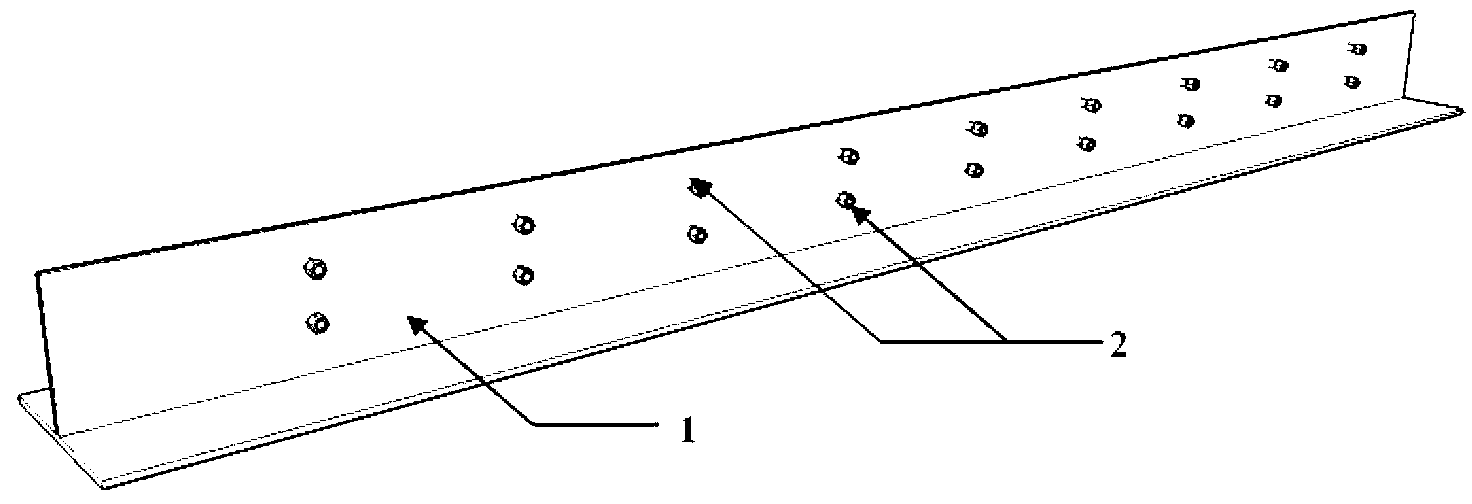

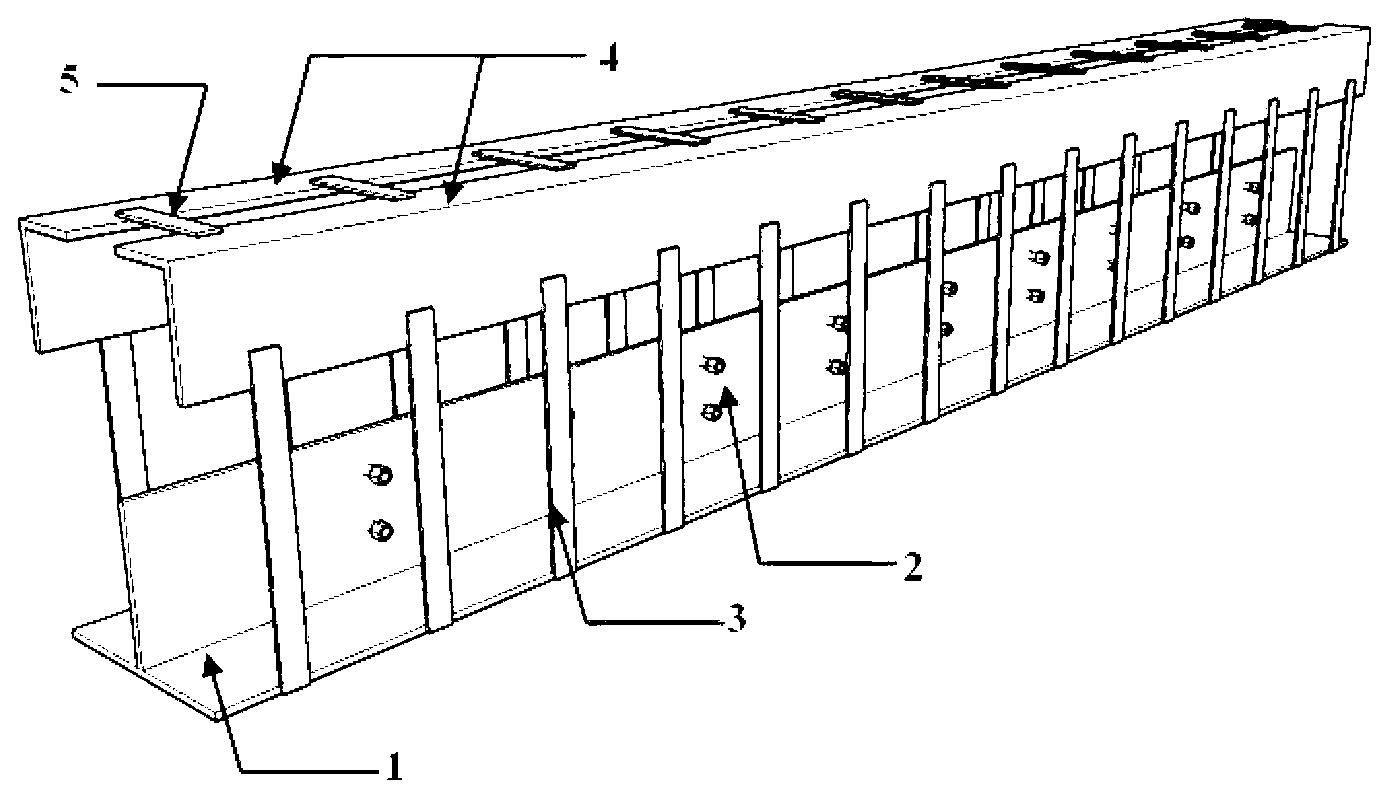

[0025] Further illustrate technical scheme of the present invention below in conjunction with accompanying drawing and embodiment:

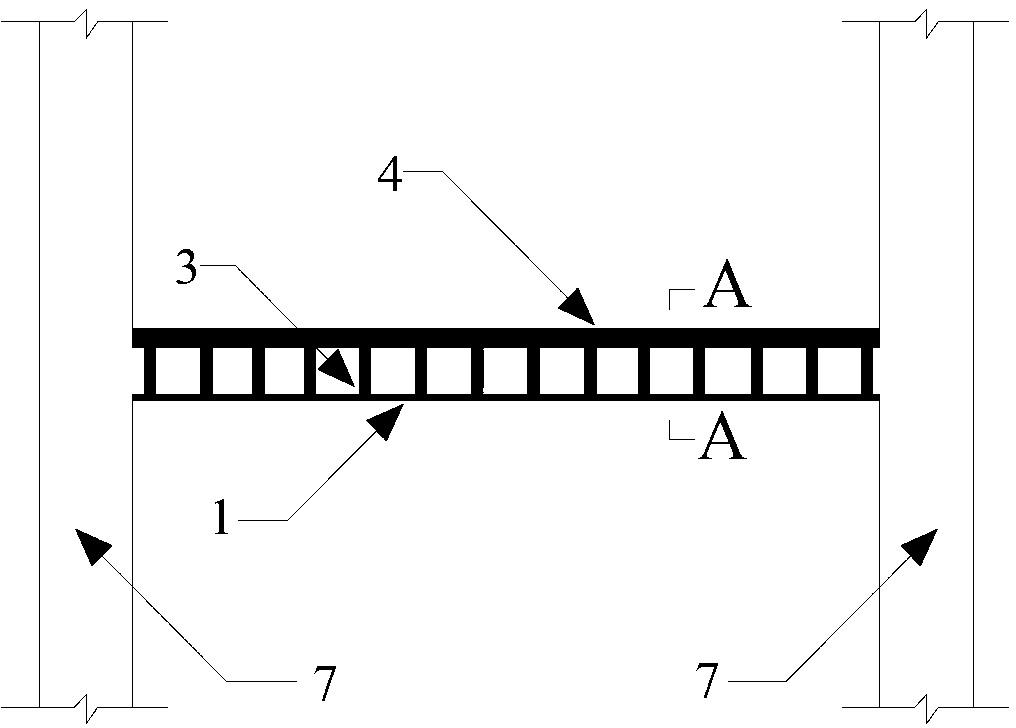

[0026] In some special structures (such as large-scale thermal power plants, long-span structures, and high-rise buildings), frames are used as part or all of their structural systems (including giant frames, frame-tube structural systems, etc.), due to the large column spacing (such as figure 1 The distance between the two columns 7) leads to an increase in the span of the beam. For ordinary RC structures, in order to meet the strength and stiffness requirements of the structure, the beam section is often designed to be large, thereby increasing the structural weight. For building structures located in earthquake zones and with high fortification intensity, the cross-sectional size of components often affects the overall seismic performance of the structure and the distribution of internal forces in the structural system, such as the phenomenon o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com