D shape guide pin top and bottom positioning structure of hole position check tool

A technology of hole position degree and positioning structure, applied in the direction of measuring device, using mechanical device, mechanical measuring device, etc., can solve the problems of difficult to reach, unable to stay at a certain height, and inconvenient to use the inspection tool, and to improve The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

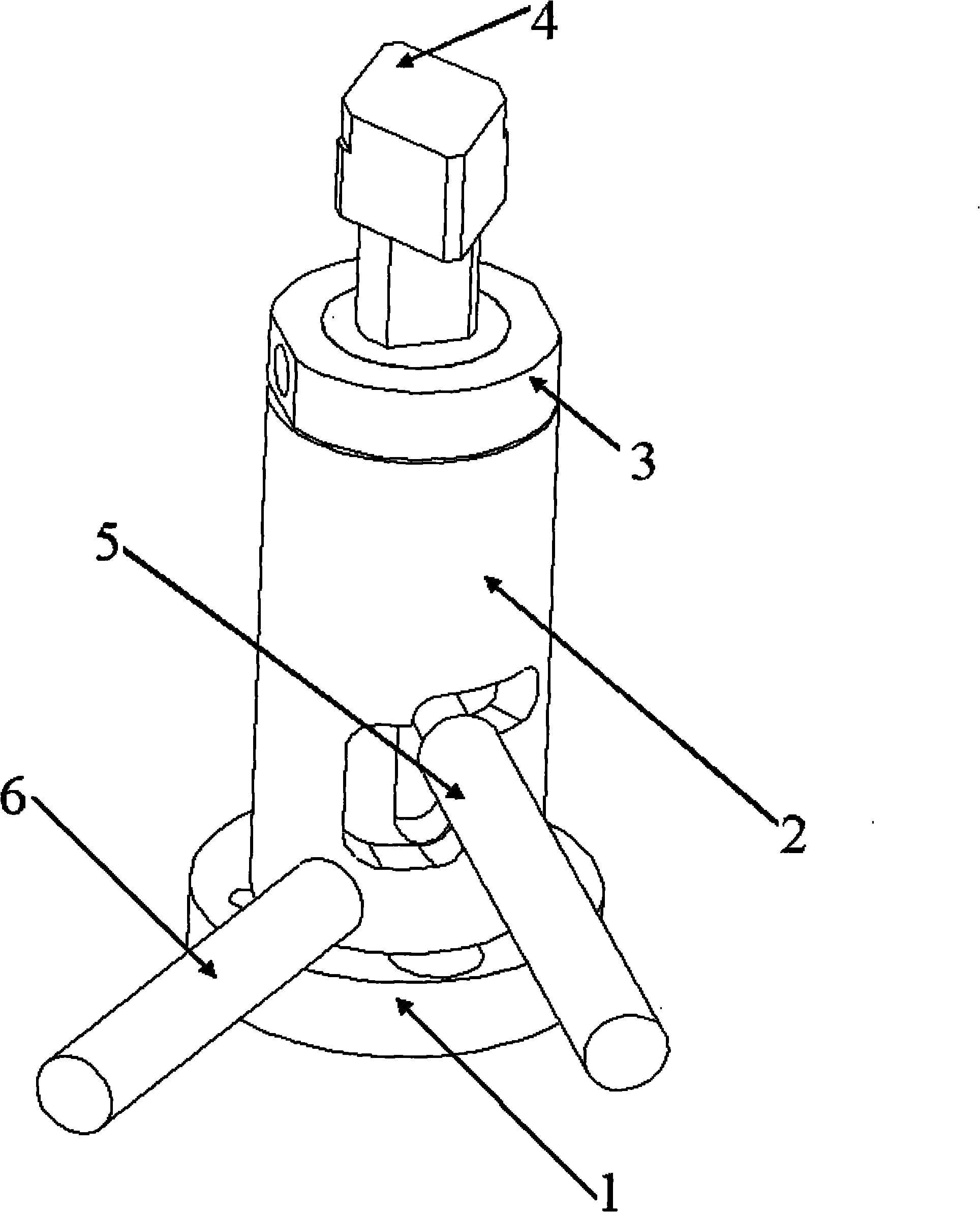

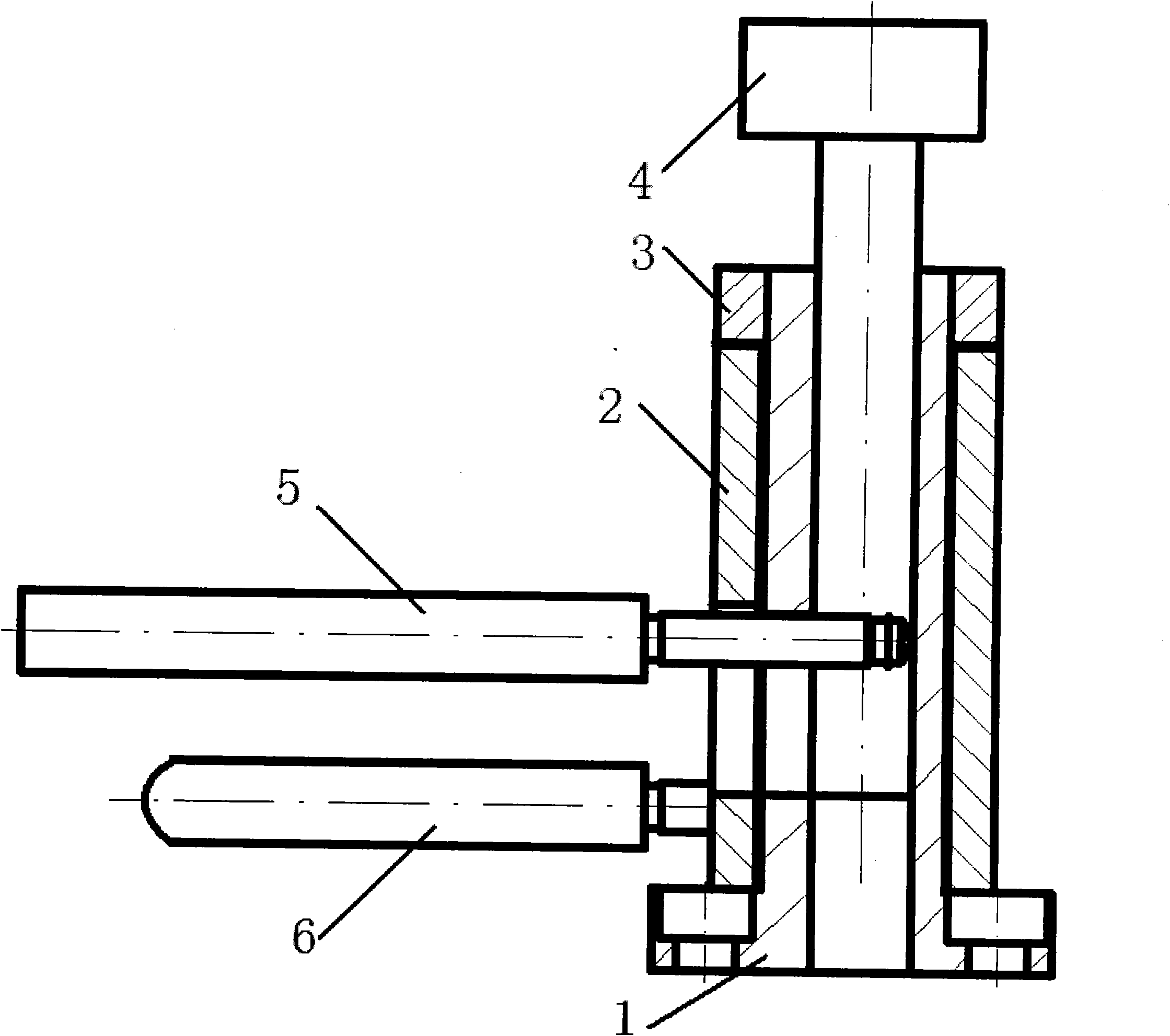

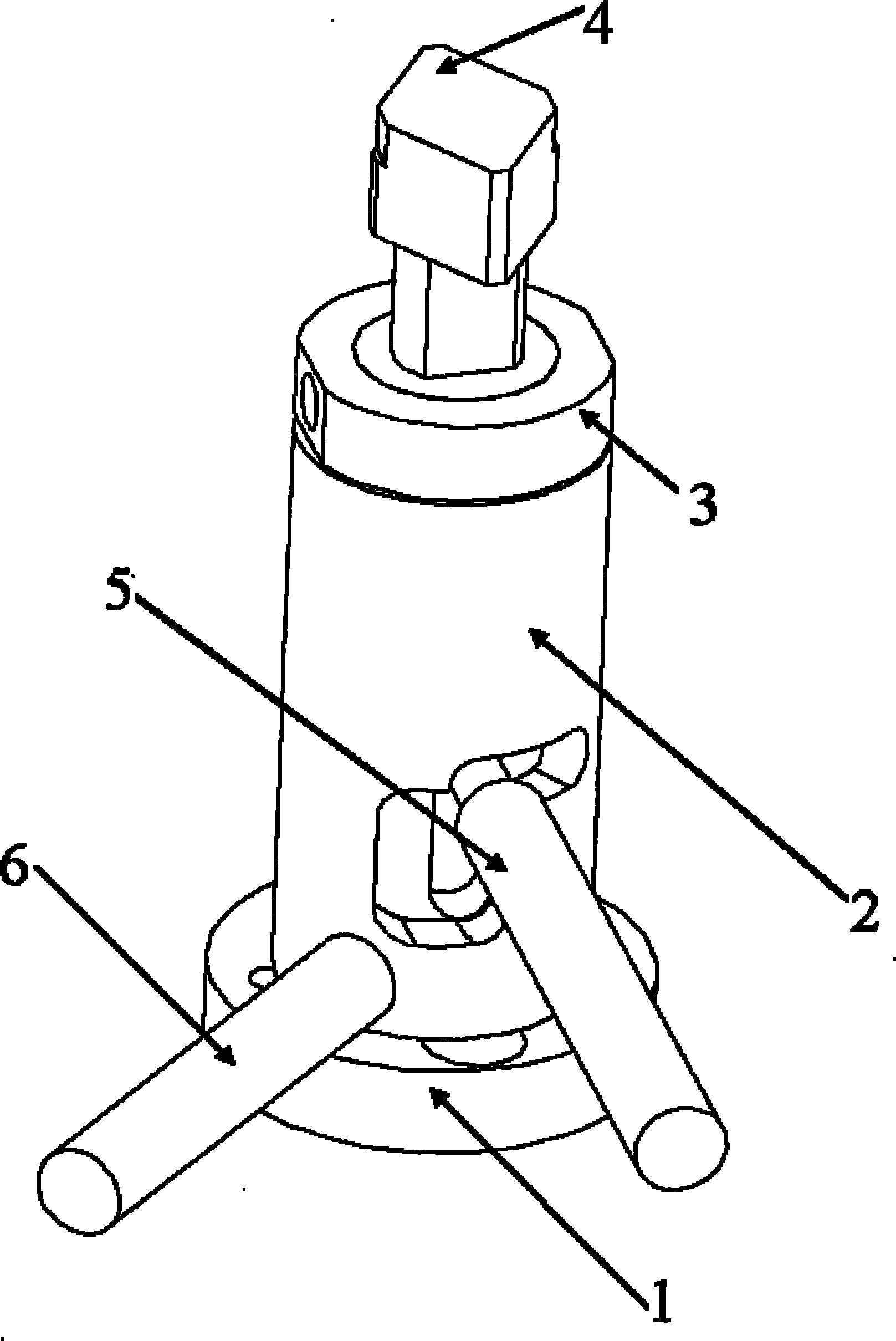

[0014] figure 1 It is a perspective view of the up and down positioning structure of the D-shaped guide pin of the hole position gauge of the present invention; figure 2 It is a sectional view of the present invention.

[0015] The upper and lower positioning structure of the D-shaped guide pin of the hole position inspection tool of the present invention includes a detection pin 4, a rotating sleeve 2, a D-shaped guide pin sliding bracket 1, a limit pressure block 3, an up and down toggle pin 5 and a rotary handle pin 6 Etc., the middle of the D-shaped guide pin sliding support 1 is hollow, and is sleeved on the outside of the detection pin 4, and the detection pin 4 can move up and down in the D-shaped guide pin sliding support 1 endoporus. A step surface with a larger diameter is provided on the lower end surface of the D-shaped gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com