Method for manufacturing overlap changeover connection node shaped like Chinese character 'mi'

A technology of cross-converting and connecting nodes, which is applied in the direction of architecture and building construction, can solve the problem of difficulty in welding thick plates with small angles, and achieve the effect of ensuring manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

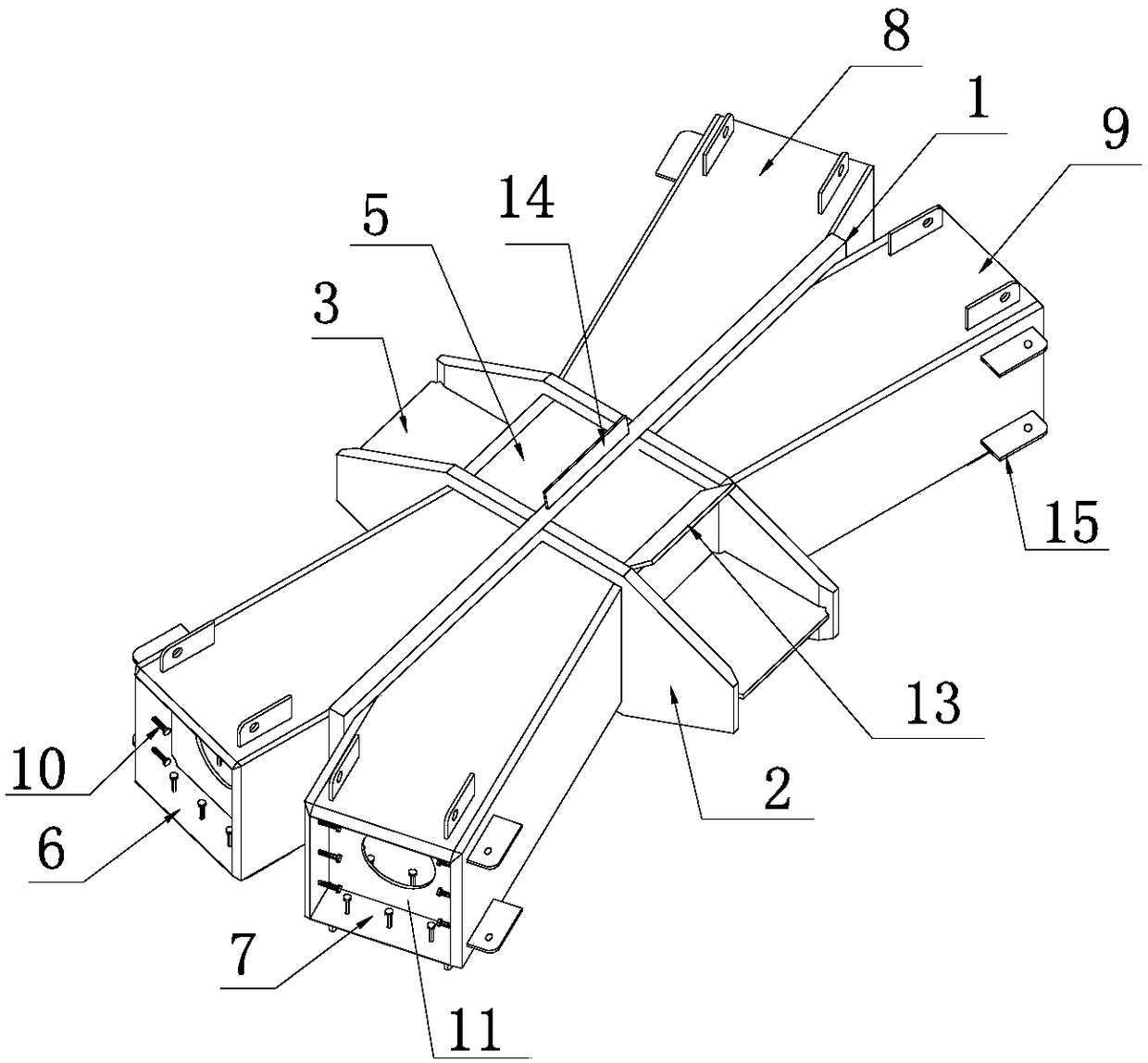

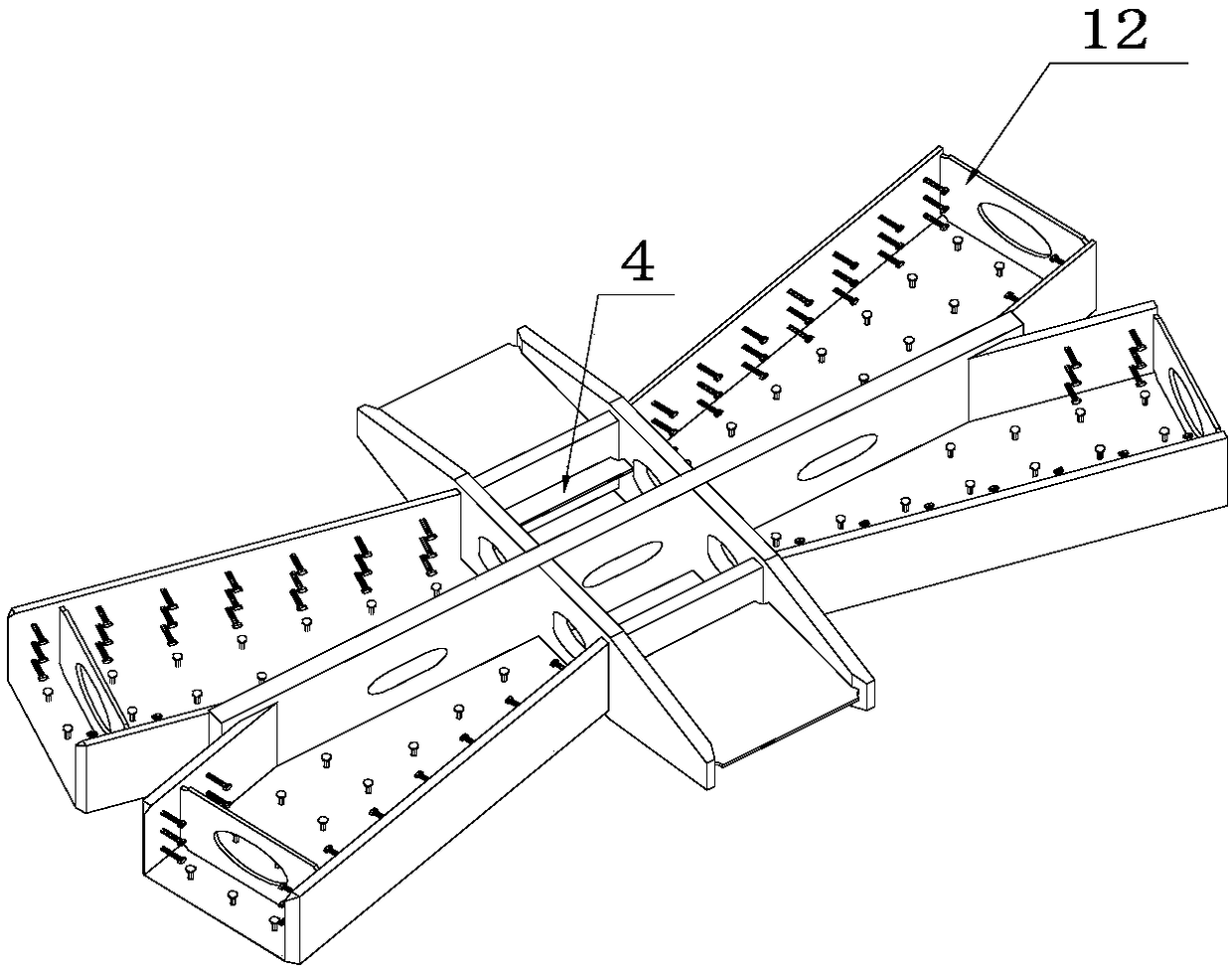

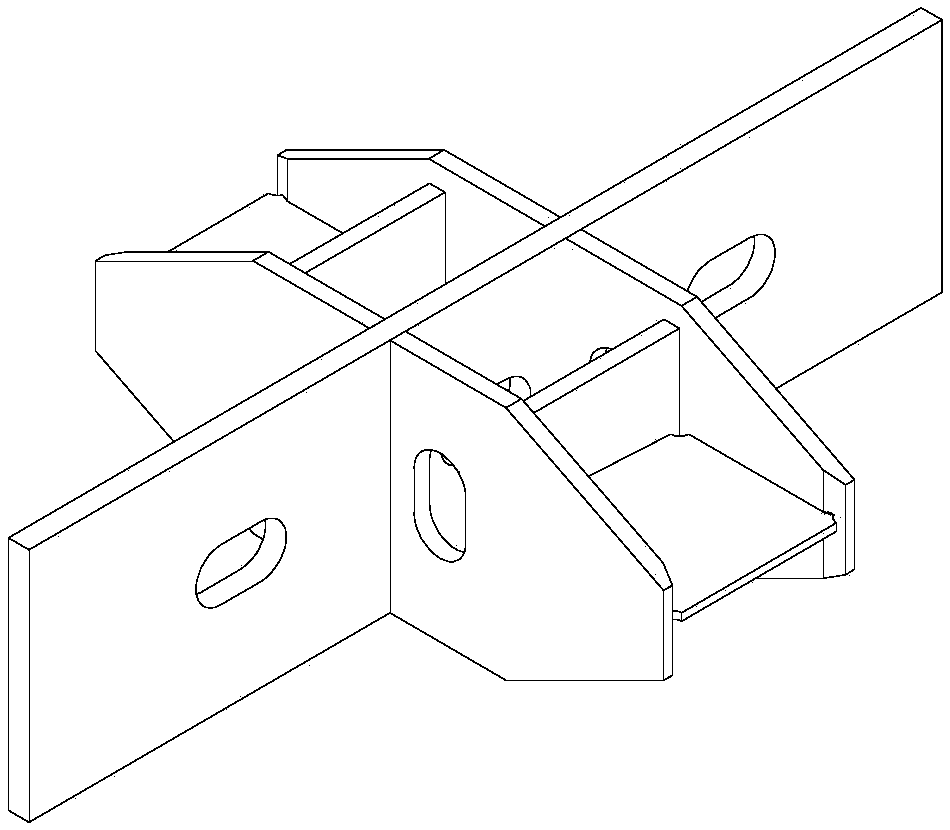

[0029] see figure 1 -2. The present invention relates to a complex rice-shaped cross conversion connection node, which is mainly composed of a middle pull plate 1, two H-shaped corbels 2, and four box-shaped corbels 3, wherein the two H-shaped corbels 2 are symmetrical Arranged on both sides of the middle tie plate 1, connected at a 90° right angle, four box-shaped corbels 3 are symmetrically arranged on both sides of the middle tie plate 1 in pairs, and arranged at an angle of 14°, and are arranged on the middle tie plate 1-1 at the same time The two box-shaped corbels 3 on one side are symmetrically arranged on both sides of the H-shaped corbel 2 on the same side, and a stiffening plate 4 is arranged inside the H-shaped corbel 2, perpendicular to the corbel wing plate, and the stiffening plate 4 Encapsulated inside by H-shaped corbel sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com