U-shaped steel-concrete composite section beam and construction method of section beam

A technology of combining sections and concrete beams, applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problems of poor corrosion resistance, long construction period, poor fire resistance, etc., and achieve high processing quality. Guaranteed, easy on-site construction, and accelerated construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

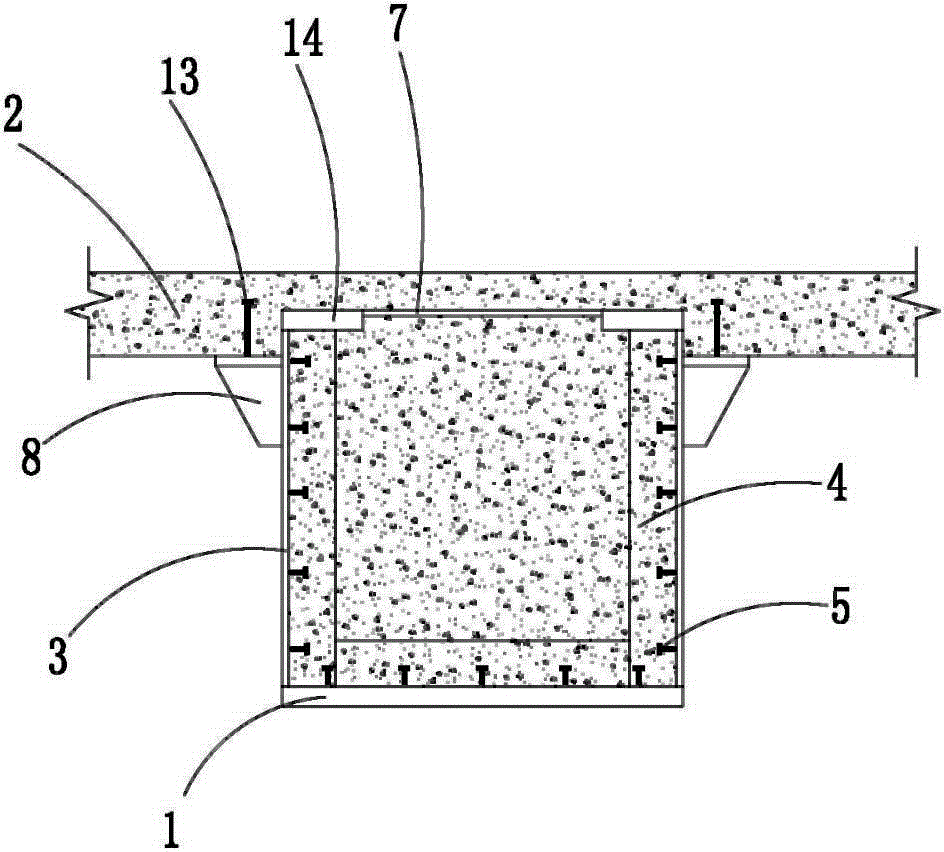

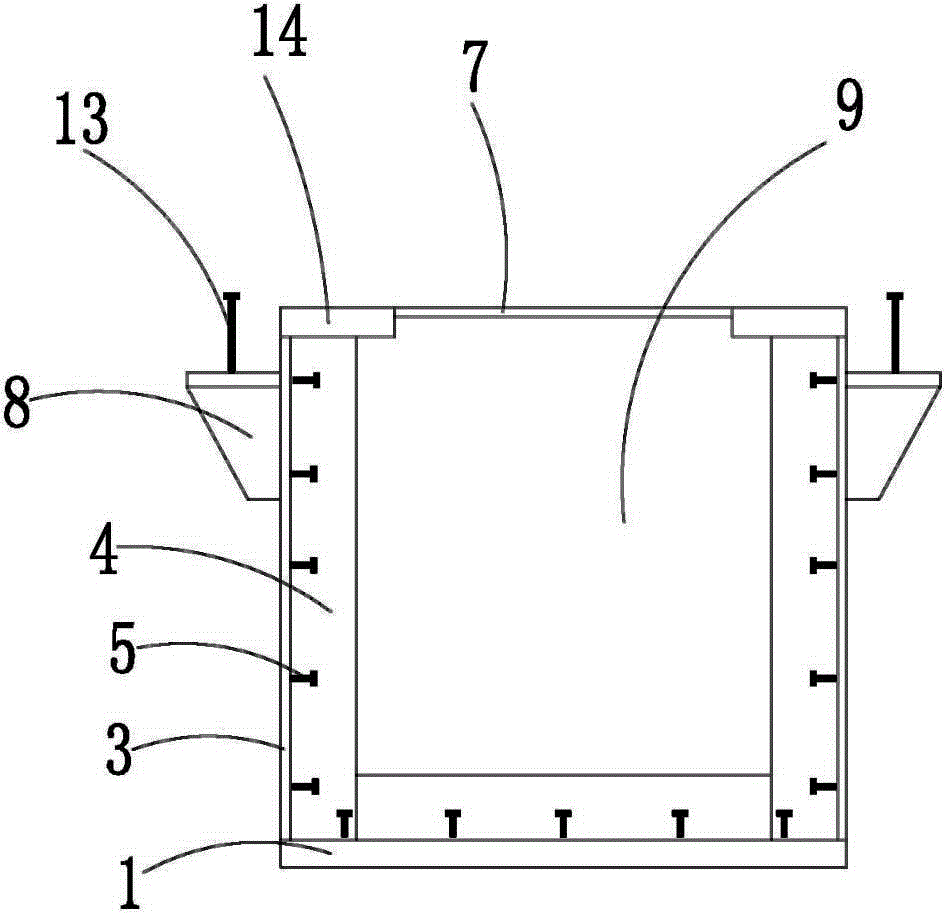

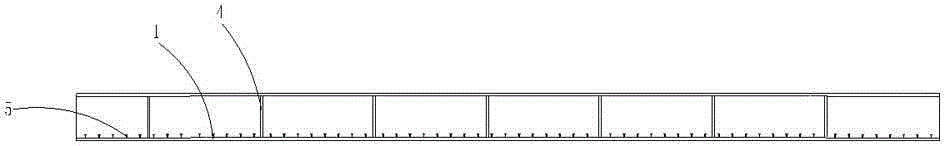

[0028] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a U-shaped steel-concrete composite cross-section beam includes a base plate 1 and a concrete beam 2, and webs 3 are respectively provided on both sides of the upper part of the base plate 1, and the inner wall of the web 3 is connected to the bottom plate 1. The upper part is provided with uniformly distributed transverse stiffeners 4 and shear studs 5 respectively, and the left and right ends of the upper part of the web 3 are respectively provided with a support section slotted top plate 6, and two support section slotted top plates 6 There are evenly distributed embossed plates 7 between them, the outer wall of the web 3 is provided with supporting corbels 8, the upper end of the web 3, the grooved top plate 6 of the support section and the embossed plate 7 are inserted into the concrete In the beam 2, the bottom plate 1, the web plate 3, the grooved top plate 6 of the support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com