Two-column pier and middle tie beam construction method employing integral movement of trusses

An integral moving, beam truss technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of slow progress of high bridge piers, affecting the surface quality of the pier body, and damaging the internal quality of concrete, achieving less construction land, The effect of saving non-structural materials and speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

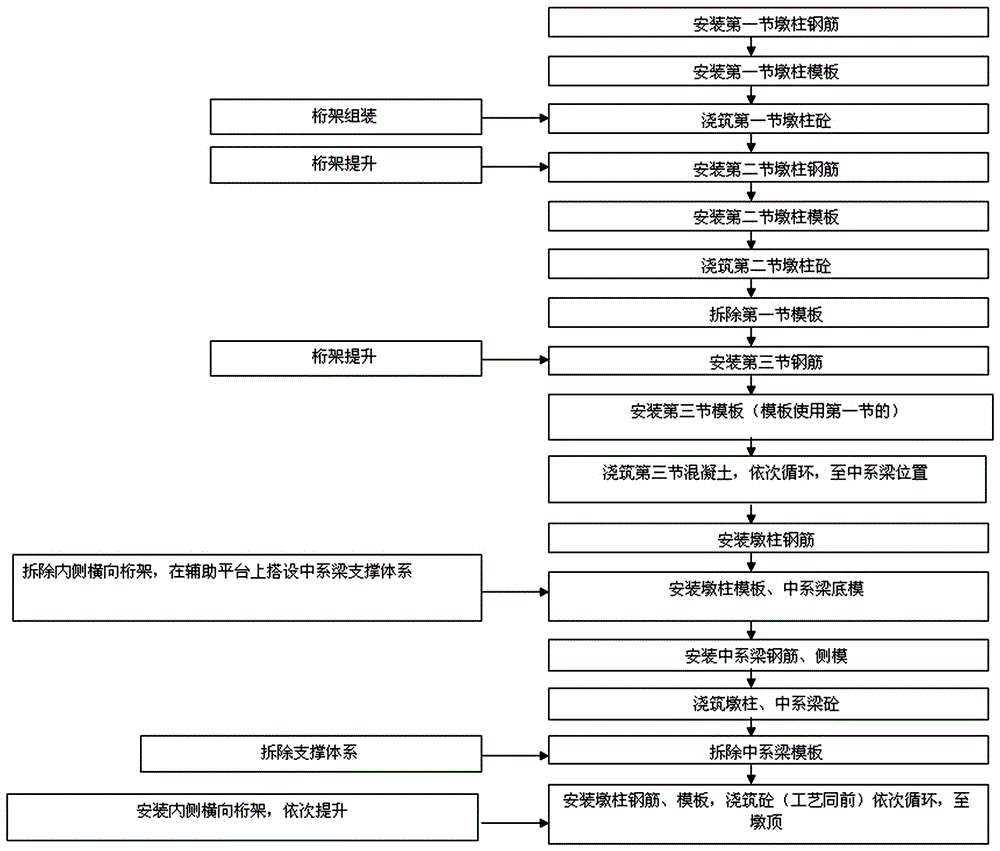

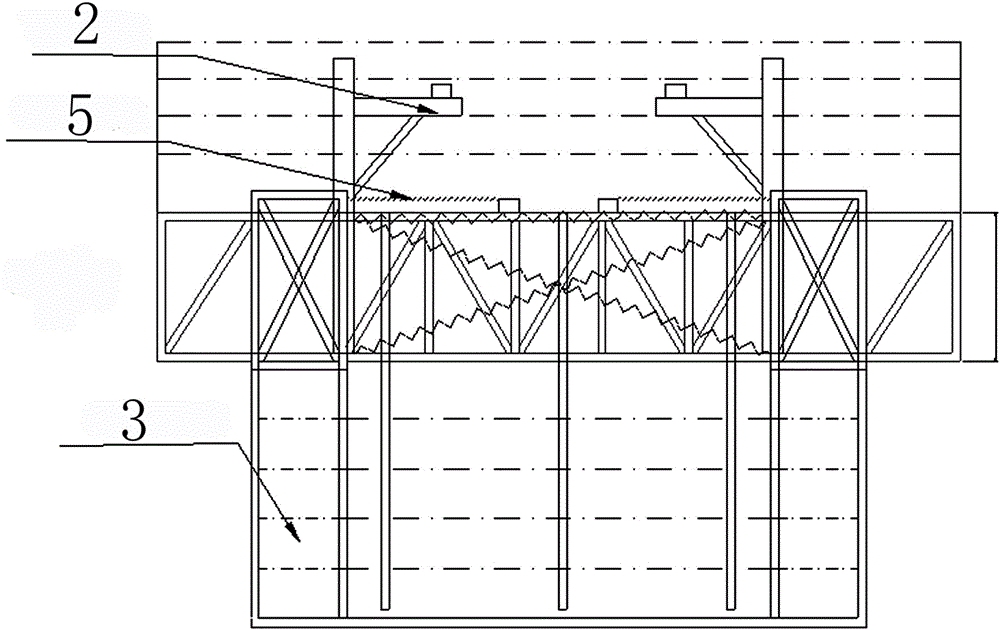

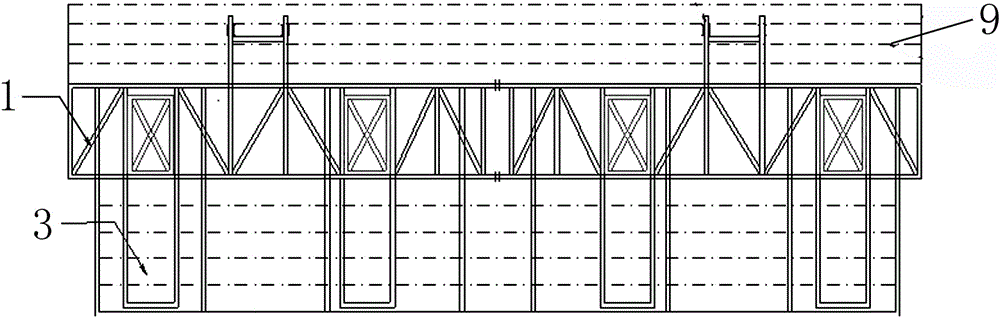

Method used

Image

Examples

Embodiment Construction

[0021] The B2-1 work area of the southeast section of the Ring Expressway in a city has a total length of 4.29km. The entire line is two-way and six-lane. There are 6 bridges with a total length of 2.32km. The pier columns are all in the form of double-column bridge piers with transverse beams installed between them. , a total of 209 pier columns, a total of 223 tie beams, and 50 pier columns larger than 40 meters. The cross-section type is a variable cross-section solid pier or a thin-walled hollow pier. The project started in September 2014 and was completed in October 2016.

[0022] The construction period of the project is tight, the quality and environmental protection requirements are high, and the risk is relatively high. Through in-depth research on the structural form and construction process of the pier body and the middle tie beam, the overall mobile construction method of the double-column pier and the middle tie beam truss is summarized, which not only meets the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com