Novel jointing construction between door or frame and wall panel of cabin

A technology for connecting structures and bulkhead panels, which is applied to hull bulkheads, hull compartments, ships, etc., can solve problems such as long production time, low space utilization, and cluttered construction sites, and achieve no impact on fire performance and space High utilization rate and clean construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

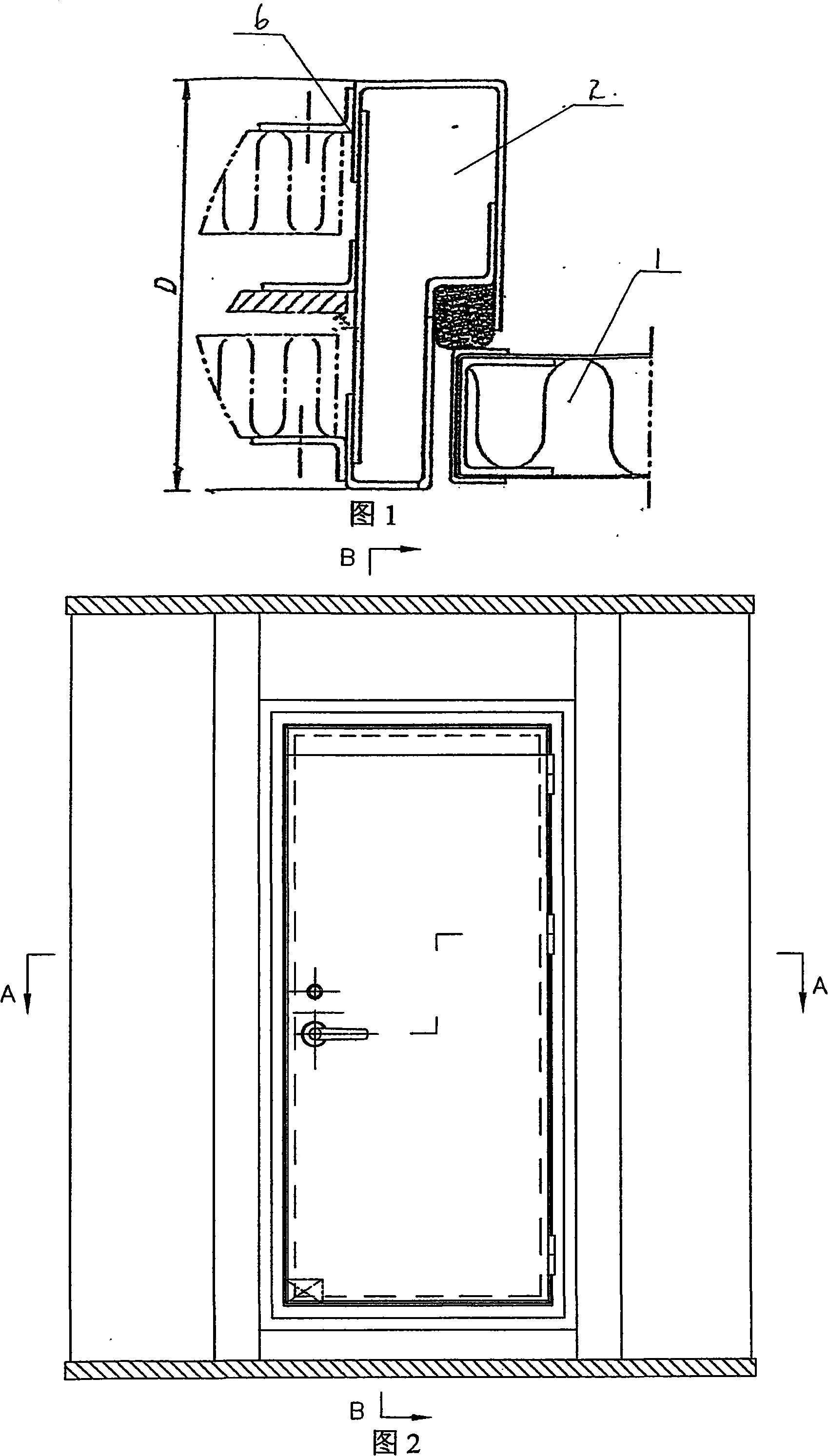

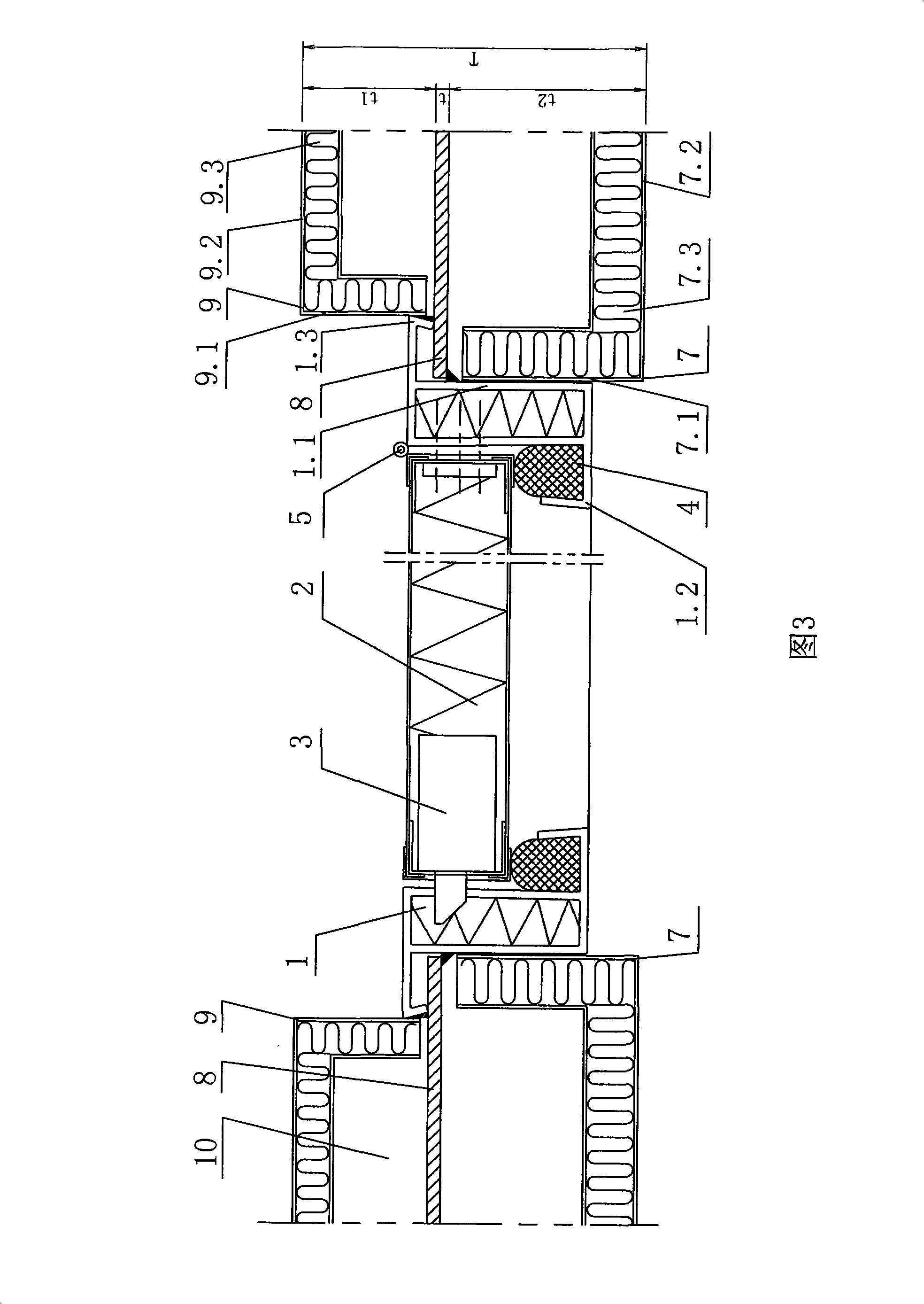

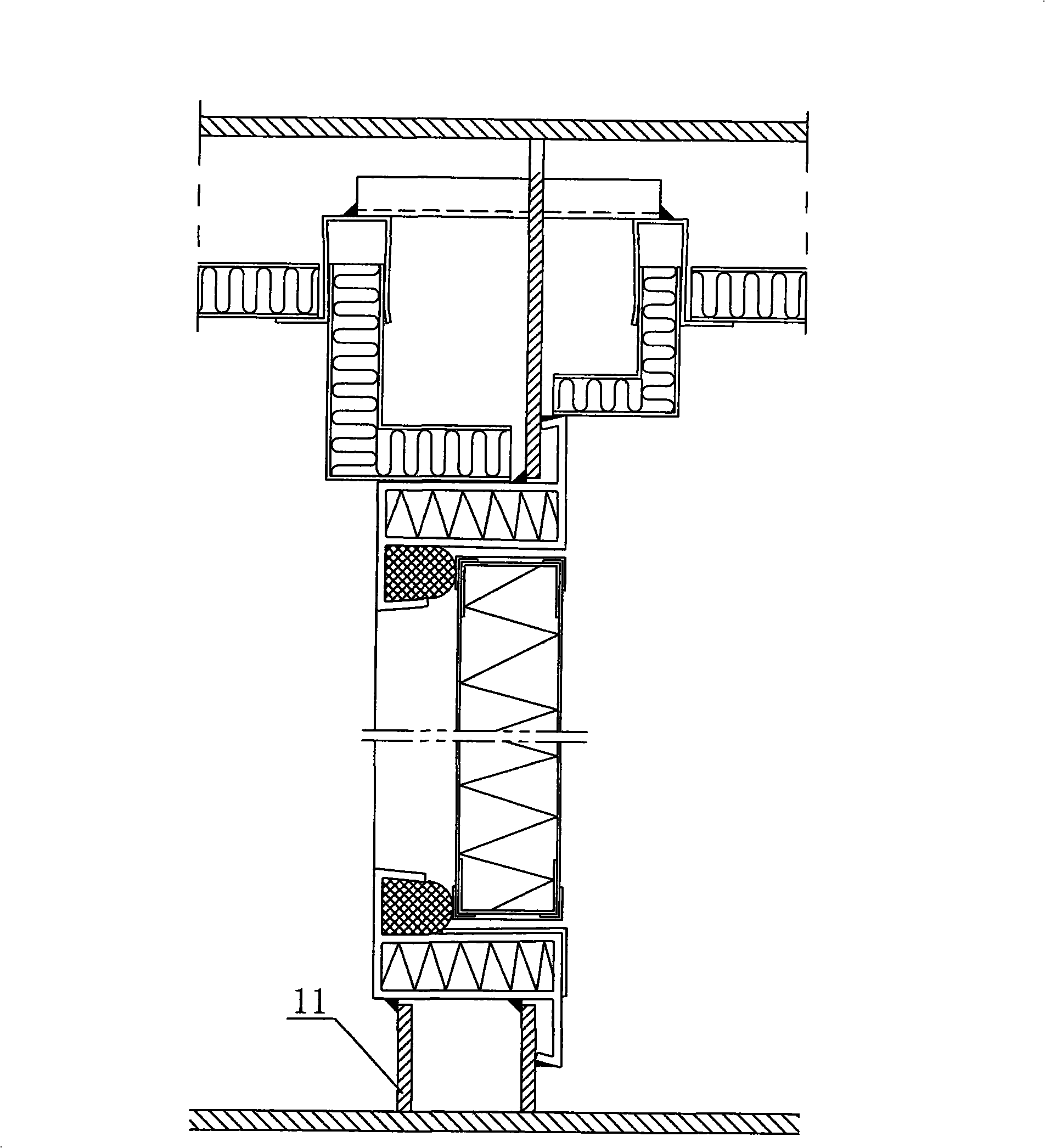

[0022] Referring to FIGS. 2-4 , the connection structure of the novel door, frame and bulkhead plate involved in the present invention mainly consists of a door frame 1 , a door leaf 2 , a door frame rubber strip 4 , a hinge 5 and a bulkhead plate 10 .

[0023] The bulkhead panel 10 is composed of a surrounding wall 8 , an indoor decorative corner panel 9 and an outdoor decorative corner panel 7 . The cross-section of the indoor decorative corner plate 9 is type structure, which is composed of indoor longitudinal side panels 9.1 and indoor transverse side panels 9.2, the interior interior decoration corner panels 9 are hollow structures, and fireproof materials 9.3 are embedded in the hollow structures, and the interior interior decoration corner panels 9 are placed in the enclosure The inner side of the wall 8, and the indoor longitudinal side plate 9.1 of the indoor side decorative corner plate 9 is indented along the surrounding wall 8 to the direction away from the door f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com