Prefabricated assembly type lightweight floor and manufacturing method thereof

A technology of prefabricated assembly and manufacturing method, applied in the direction of floor slab, building structure, building components, etc., can solve the problems of low strength and self-heavy weight of hollow floor slab and lightweight concrete, achieve great practical significance and engineering application value, reduce weight , Solve the effect of low strength of lightweight concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

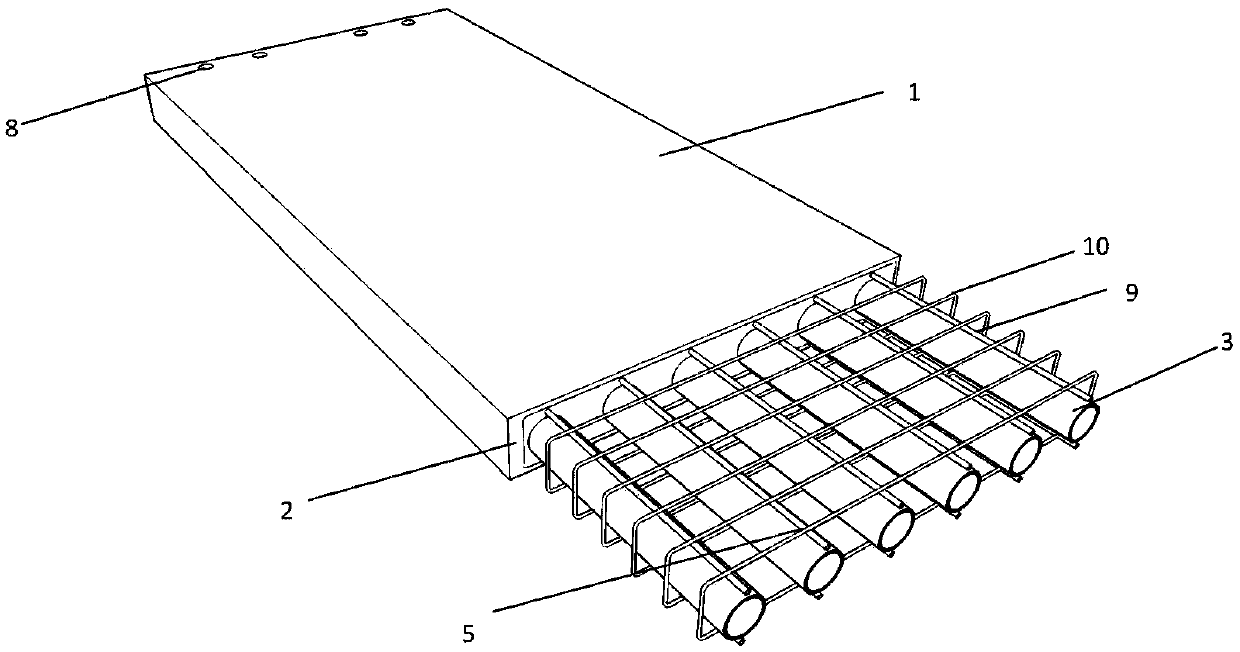

[0091] Embodiment 1: The prefabricated lightweight floor slab of the present invention

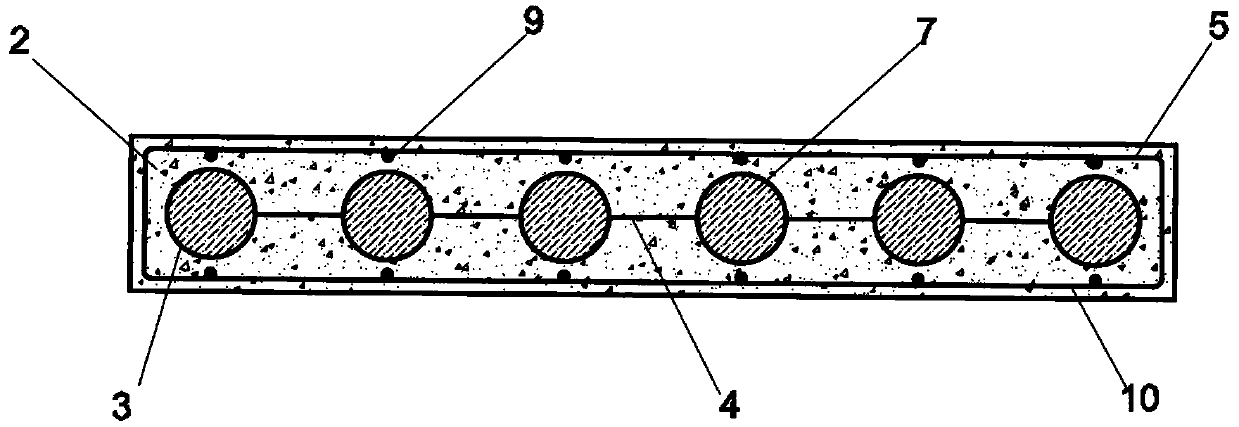

[0092] Such as Figure 1-3 , this embodiment 1 provides a prefabricated lightweight floor slab, the composition of this lightweight floor slab 1 includes concrete matrix 2, hollow steel pipe 3, embellishment plate 4, steel grid frame 5, hollow steel pipe hole 6, lightweight filling material 7 and peg hole 8;

[0093] The concrete matrix 2 is poured inside the reinforced grid 5;

[0094] The hollow steel pipe 3 is located inside the reinforced grid 5;

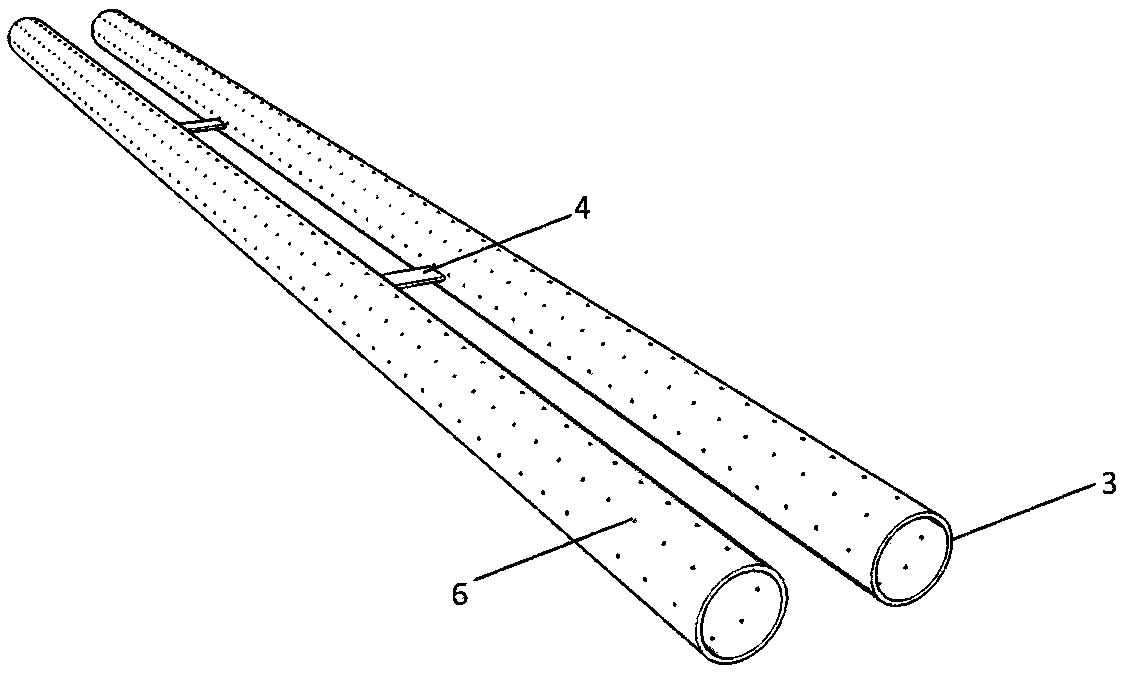

[0095] The trim plate 4 is connected to two adjacent hollow steel pipes 3;

[0096] The steel grid frame 5 is formed by connecting longitudinal bars 9 and stirrups 10;

[0097] The hollow steel pipe holes 6 are distributed on the body of the hollow steel pipe 3;

[0098] The lightweight filling material 7 is filled inside the hollow steel pipe 3;

[0099] The peg holes 8 are distributed on the body of the lightweight floor 1 .

[0100...

Embodiment 2

[0144] Embodiment 2: Preparation of prefabricated light-weight floor slab of the present invention

[0145] This embodiment 2 provides a method for manufacturing a prefabricated lightweight floor slab in embodiment 1, including the following steps:

[0146] Step 1: binding the longitudinal bars 9 and the stirrups 10 to form a cross-section closed steel bar grid 5;

[0147] Step 2: filling the hollow steel pipe with lightweight filling material, and placing the hollow steel pipe 3 on the positioning support according to a certain interval;

[0148] Step 3: Weld the adjacent hollow steel pipes 3 together with the trim plate 4 to form the skeleton of the hollow steel pipes;

[0149] Step 4: Put the hollow steel pipe skeleton obtained in Step 3 into the reinforced grid frame 5 obtained in Step 1;

[0150] Step 5: Install baffles around the outer sides of the reinforced grid frame 5 with hollow steel pipe skeletons inside the obtained step 4, and pre-embed corrugated pipes at the...

Embodiment 3

[0154] Embodiment 3: The use of the prefabricated light-weight floor slab of the present invention

[0155] Such as Figure 4-5 , this embodiment 3 provides an assembly method of a prefabricated lightweight floor slab in embodiment 1. A stud is welded on both wings of the steel beam, and then the stud is respectively inserted into two adjacent lightweight floor slabs 1 In the center of the stud hole 8, the extra longitudinal reinforcement 9 is bound, the extra space inside the stud hole 8 is poured with ordinary concrete, and finally the gap between the steel beam and the two lightweight floor slabs 1 is filled with high-performance Concrete 11 pouring.

[0156] Preferably, the peg is a steel nail with a cap diameter of 50mm and a nail body diameter of 20mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com