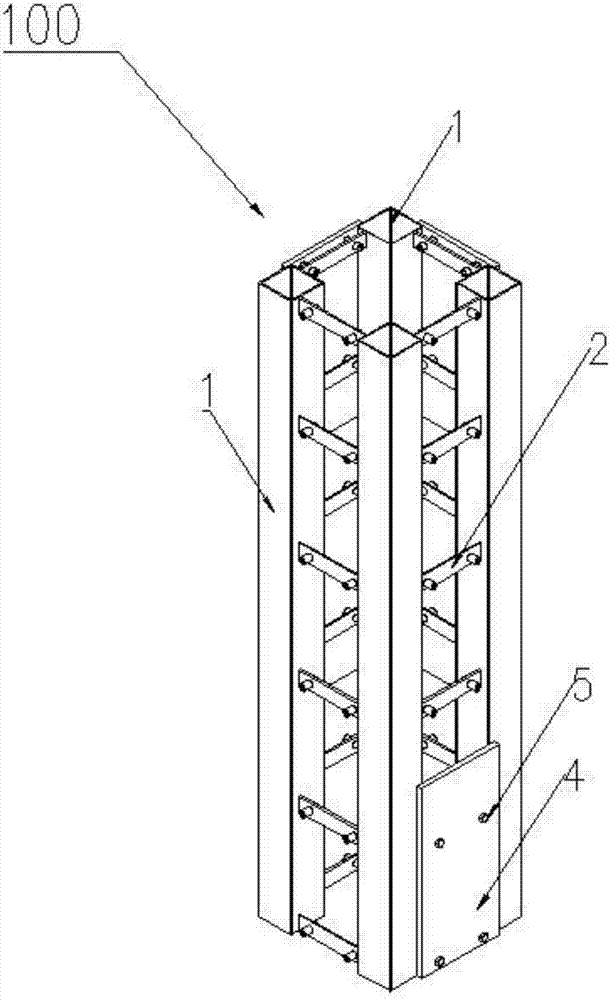

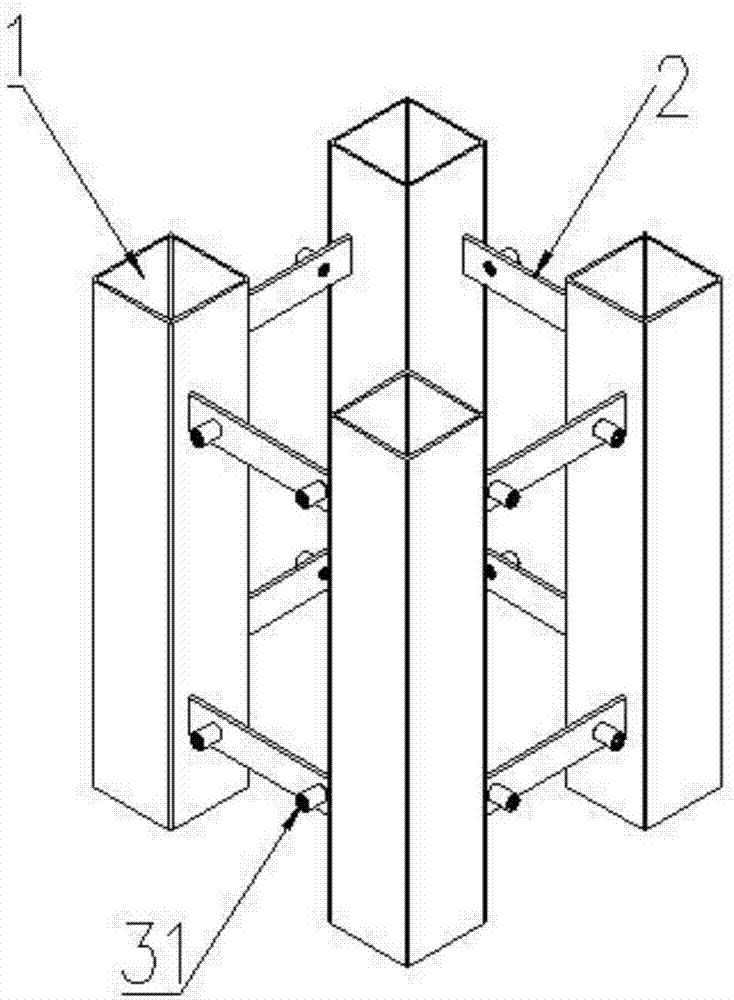

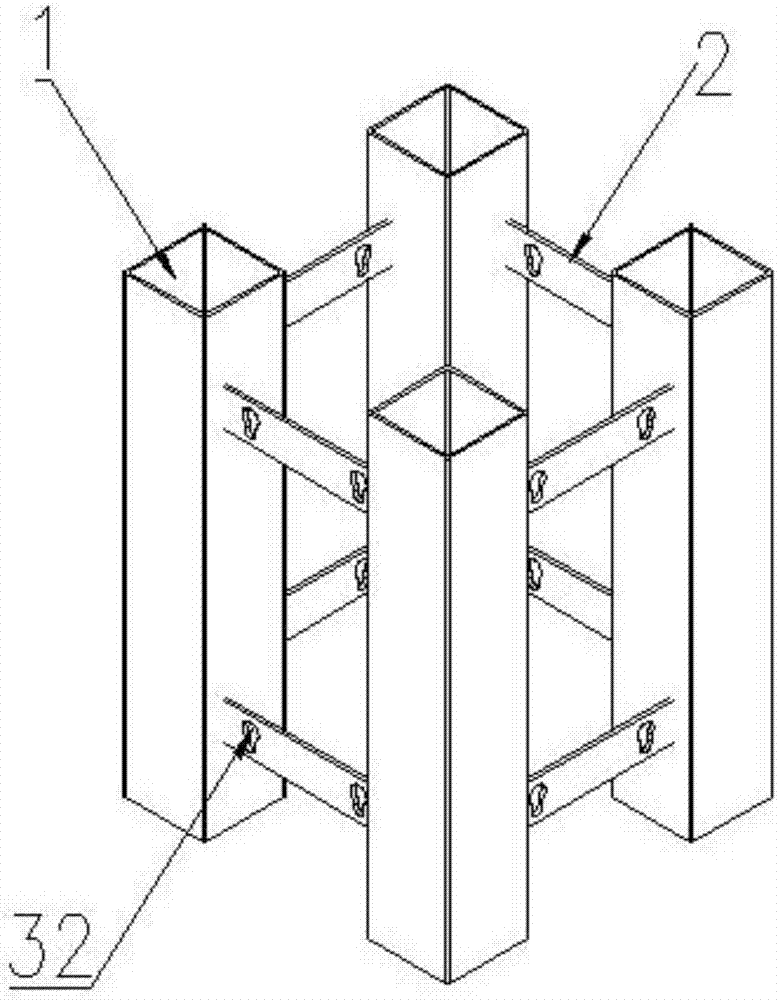

Steel pipe-batten plate combined building column and construction technology thereof

A technology of cladding and steel pipes, which is applied in the field of building columns combined with steel pipes and claddings and its construction technology, can solve the problems of poor economy, large steel consumption, and high cost, and achieve good force, less steel consumption, and reduced The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The construction column of the present invention combined with steel pipes and panels and its construction process will be described in more detail below in conjunction with schematic diagrams, wherein a preferred embodiment of the present invention is shown, and it should be understood that those skilled in the art can modify the present invention described here, while still achieving the advantageous effects of the present invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

[0031] In order to make up for the defects of the prior art, the present invention proposes a new type of building independent column design, manufacture and construction method ----- the building column combined with the steel pipe and the panel and its construction technology, the principle is simple, the production is convenient, and the cost is low. It is lower than the tradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com