Steel truss support unloading structure and construction method for unloading tracks by using same

A steel truss and track technology, applied in the field of steel truss support unloading structure and unloading method, can solve the problems of inability to recycle, high cost, and inability to completely dismantle the sliding track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

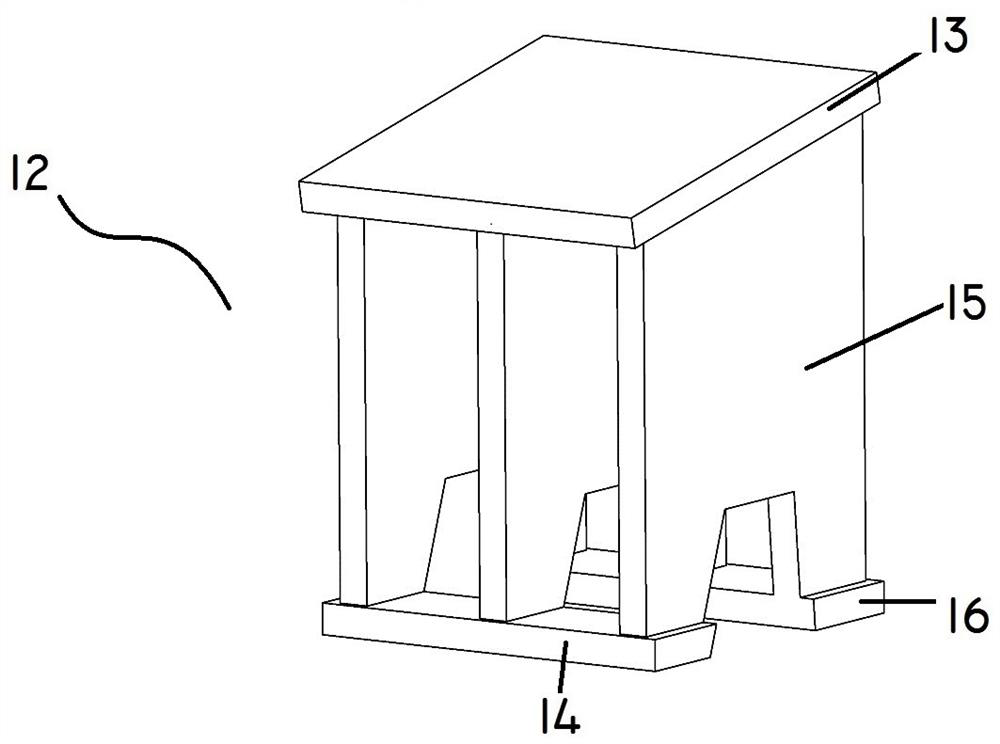

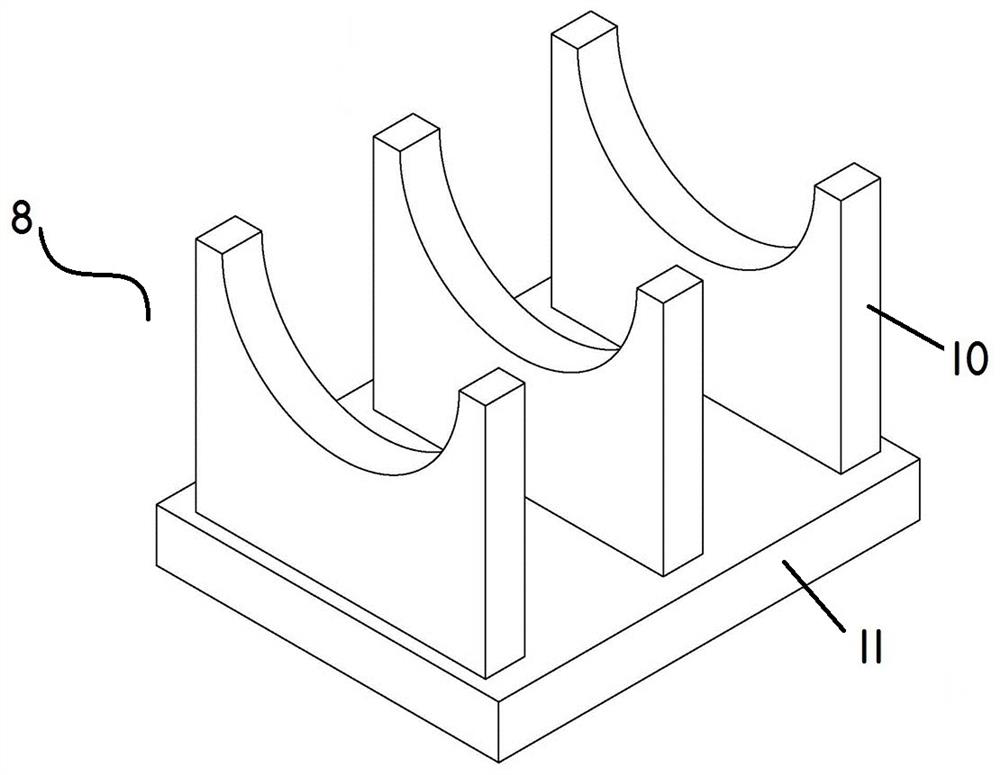

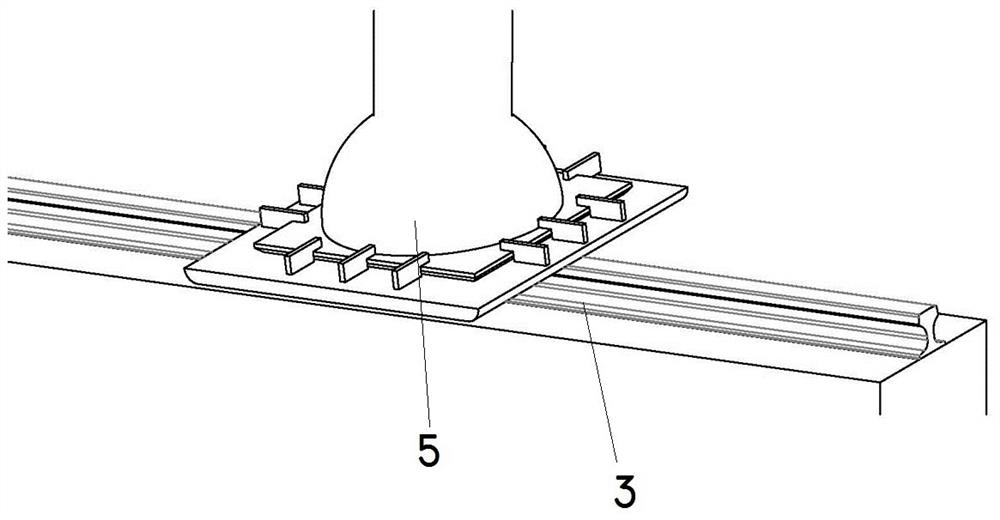

[0038] Such as Figure 7 As shown, the present invention provides a steel truss support unloading structure, including at least three steel trusses 1, connecting pipes 2 symmetrically arranged in the middle of both sides of the steel trusses 1, and rails 3 symmetrically arranged at the bottom of the steel connecting beams. The disassembly structure includes the steel column limb 4, the hemisphere 5 arranged at the bottom of the steel column limb 4, the sliding shoe 6 clamped on the track 3, the pressure plate 7 for fixing the sliding shoe 6 and the hemisphere 5, symmetrically arranged on the steel column limb 4 The support assembly on both sides, the support assembly includes a pipe support 8, a jack 9 and a jack base 12, the jack base 12 is arranged on the track 3, the lower end of the connecting pipe 2 is set on the pipe support 8, and the jack 9 is arranged on the pipe support 8 Between the bottom and the jack base 12. The bottom of the hemisphere 5 is provided with a squa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com