Piston diameter changeable air spring

A technology of air spring and piston diameter, which is applied in the direction of spring, spring/shock absorber, gas shock absorber, etc. It can solve the problems of inability to effectively adjust the stiffness characteristics of the air spring and the inability to realize variable stiffness control of the suspension, and achieve high Flexibility and reliability, easy implementation, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

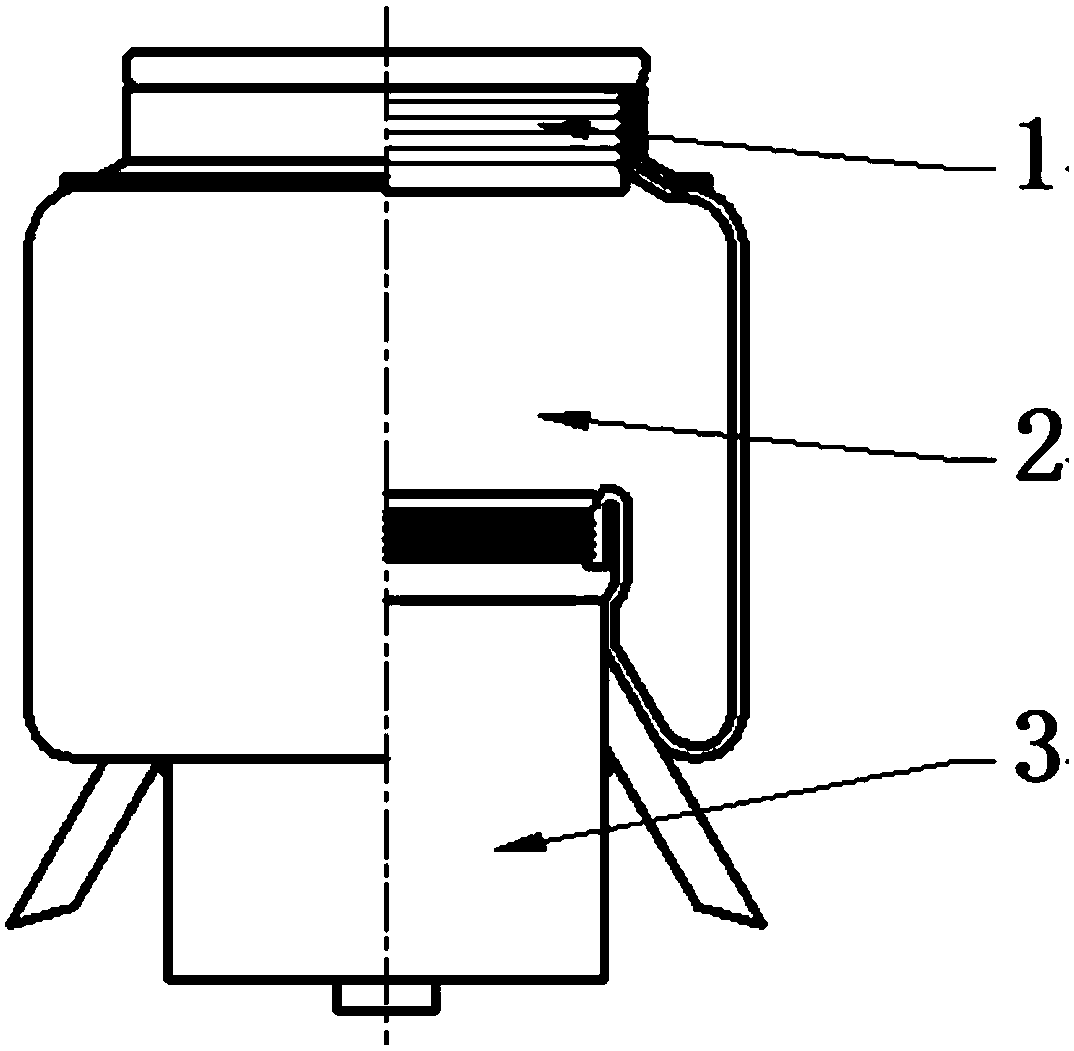

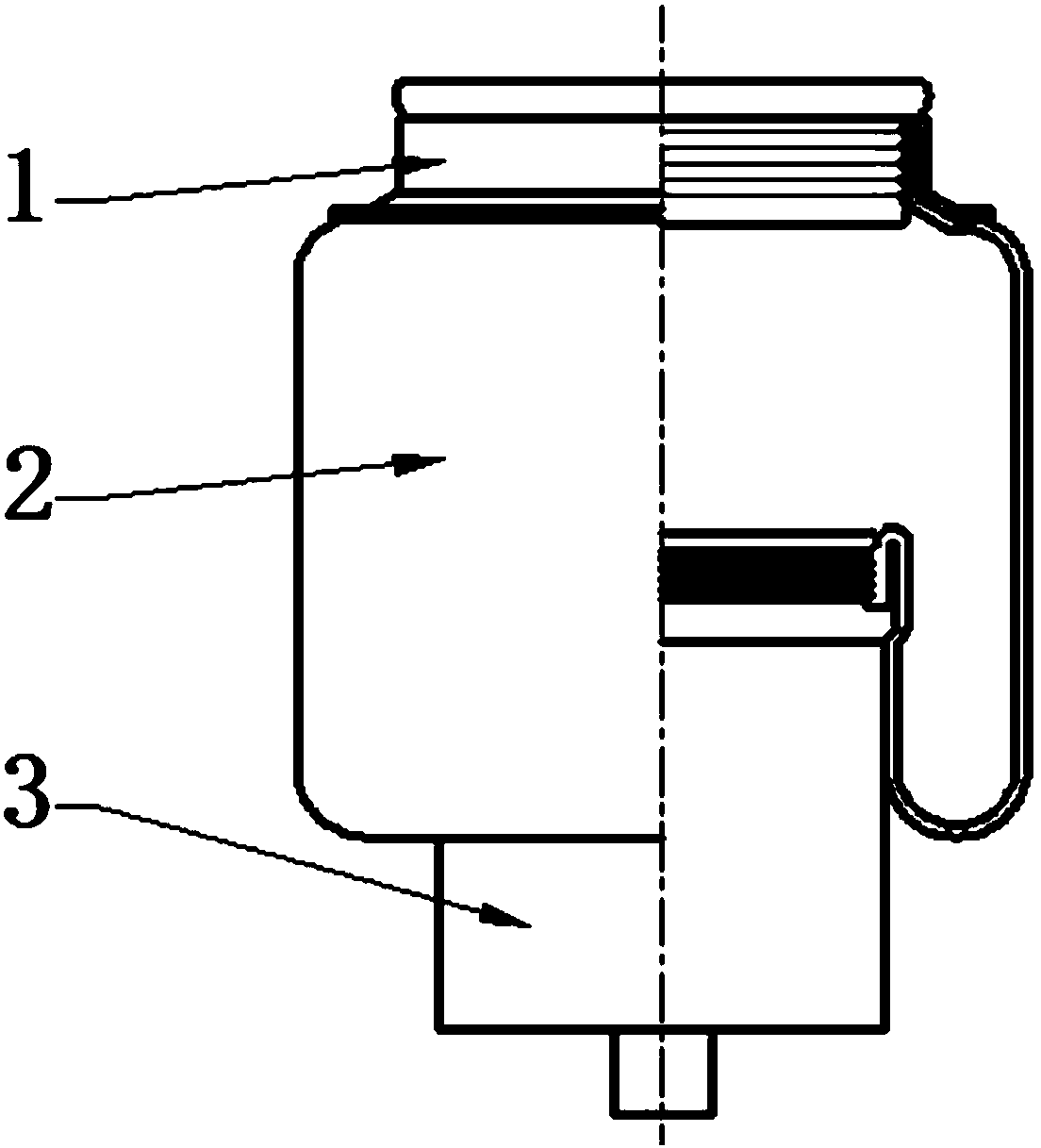

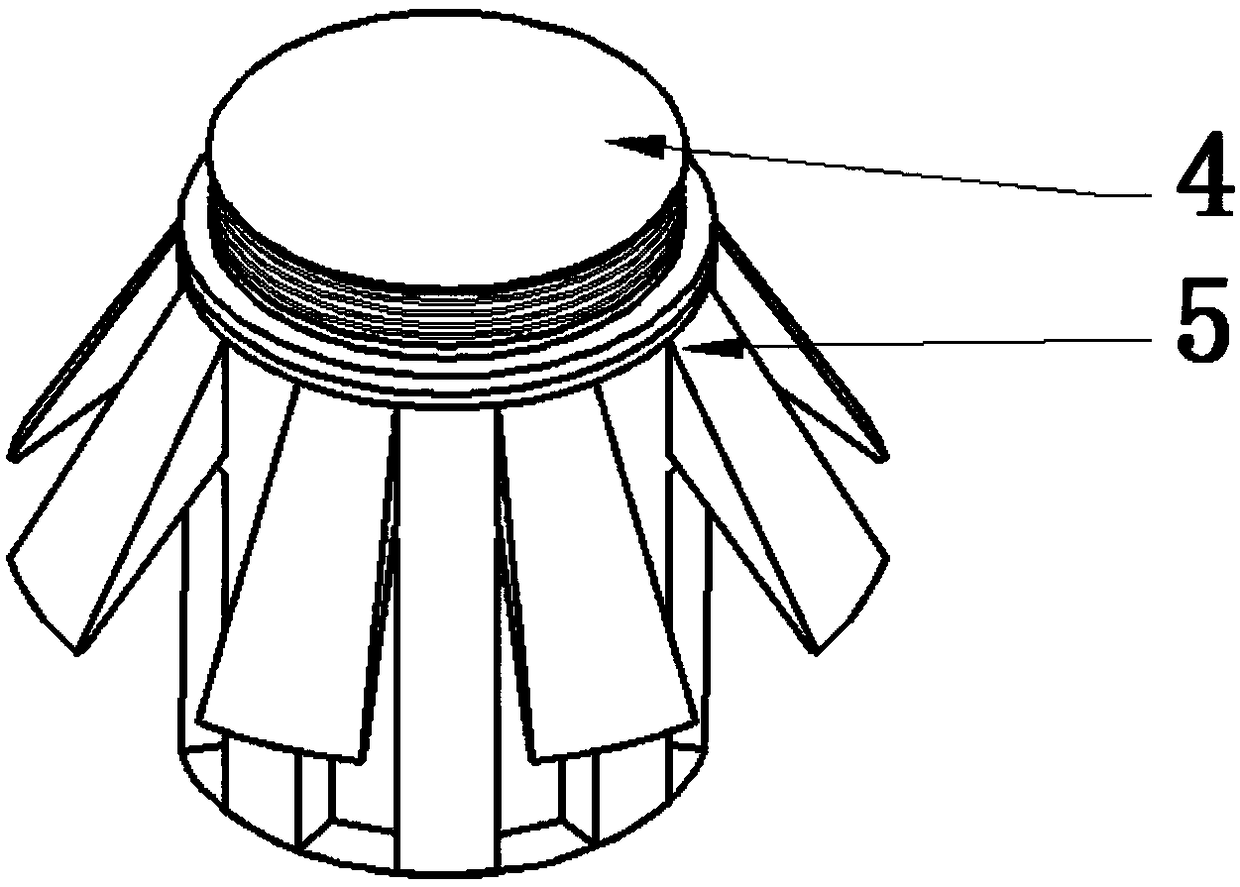

[0032] Such as Figure 1 to Figure 5 As shown, an air spring with a variable piston diameter includes a cover plate 1, a rubber air bag 2, and a piston assembly 3. The lower port of the cover plate 1 is press-fitted with a rubber air bag 2, and the lower port of the rubber air bag 2 Press-fitted on the piston assembly 3, the piston assembly 3 includes a hollow columnar piston frame 4, a piston push rod 7 that is slidingly fitted at the bottom of the piston frame 4, and is evenly hinged in the circumferential direction. The eight piston petals 5 on the circumferential wall of the piston skeleton 4, the piston ejector rod 7 and the middle part of each piston petal 5 are all articulated through the connecting rod 6 to form eight groups of crank slider mechanisms, and each piston petal 5 is hinged by a hinge The piston skeleton 4 is connected an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com