Combined type damping bolted connection joint

An anti-seismic screw and bolt connection technology, which is applied in the direction of anti-seismic, protective buildings/shelters, building components, etc., can solve the problems of insufficient consideration of cyclic and repeated actions, dissipation of seismic capacity and bearing capacity, etc., to avoid welding residual stress , reliable bearing capacity, force principle and direct effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

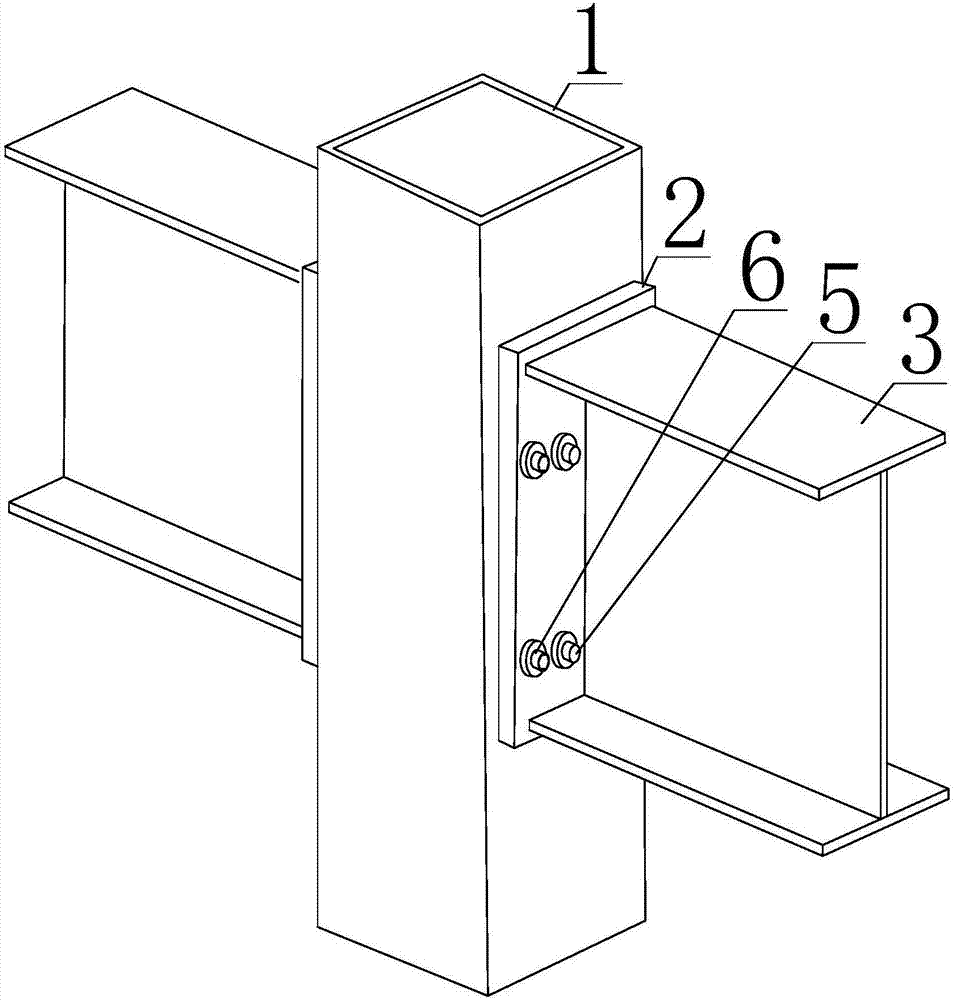

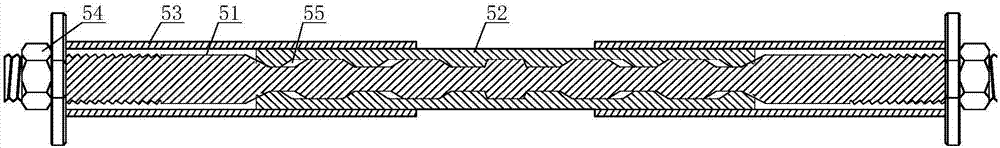

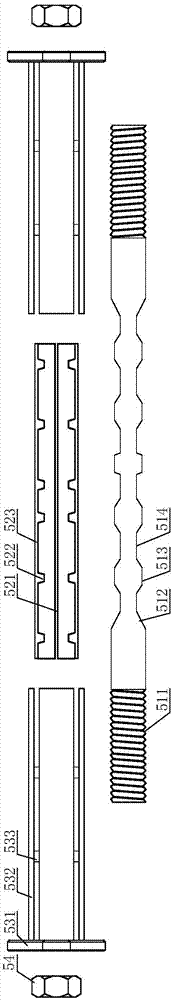

[0032] Such as Figure 1 ~ Figure 3 As shown, a combined anti-seismic bolt connection node includes a square steel pipe 1, a connecting end plate 2, a steel beam 3, a low-yield spacer 5 and a single-sided bolt 6, wherein the connecting end plate 2 is rectangular, and its number is Two pieces, the two connecting end plates 2 are respectively parallel to and in contact with the outer side walls of the opposite sides of the square steel pipe 1 . The steel beam 3 of this embodiment is I-shaped or H-shaped, and the number of steel beams 3 is two. One end of the steel beam 3 is vertically fixedly connected to the side wall of the other side of the connecting end plate 2 that is in contact with the side of the square steel pipe 1. , the two steel beams 3 are connected to the two connecting end plates 2 in one-to-one correspondence, and the flange plates of the steel beams 3 are perpendicular to the axial direction of the square steel pipe 1 . In this embodiment, when specifically co...

Embodiment 2

[0044] Such as Figure 4 As shown, the present embodiment has made the following improvements on the basis of Embodiment 1: the present embodiment also includes an angle steel limit piece 4, wherein the angle steel limit piece 4 includes a limit tube 41 and an angle steel 42, and a piece of the angle steel 42 The rectangular panel is in contact with the web of the steel beam 3 and is fixed on the web of the steel beam 3 by positioning bolts 43 , and the other rectangular panel is parallel to the connecting end plate 2 . In this embodiment, the limiting tube 41 is vertically fixedly connected to the angle steel 42 parallel to the outer sidewall of the rectangular panel connecting the end plate 2 , and one end of the limiting tube 41 not connected to the angle steel 42 is facing the connecting end plate 2 . In this embodiment, each steel beam 3 is connected with an angle steel limit piece 4, and the end of the low yield locator 5 is embedded in the limit tube 41, specifically, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com