Cast-in-place concrete large-size core formwork hollow floor anti-floating structure and construction method

A hollow floor and concrete technology, applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of labor-intensive iron wire cleaning, etc., achieve reliable bearing capacity, solve the problem of excessive openings, and speed up the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

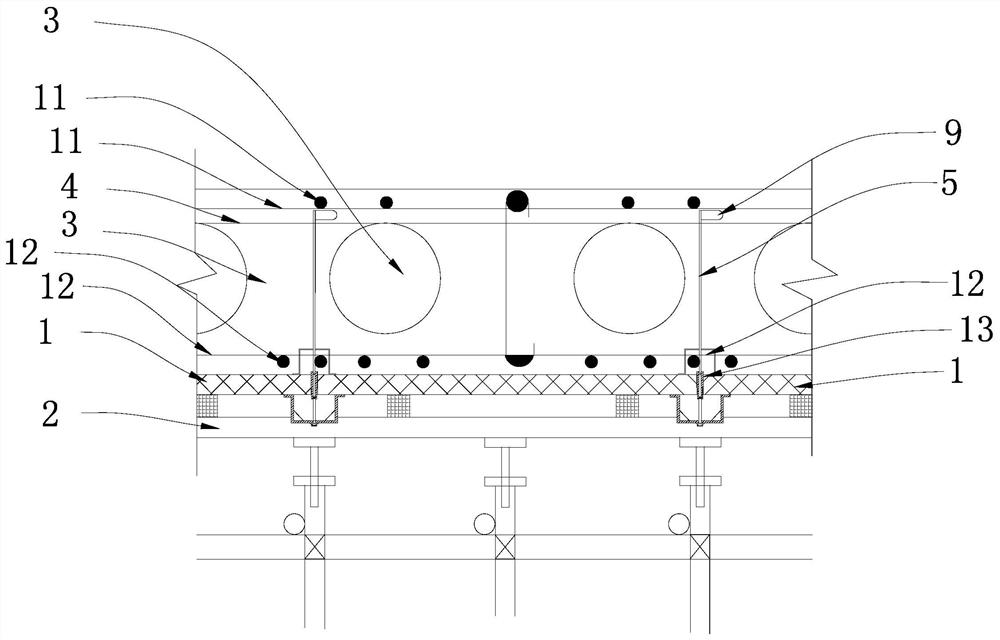

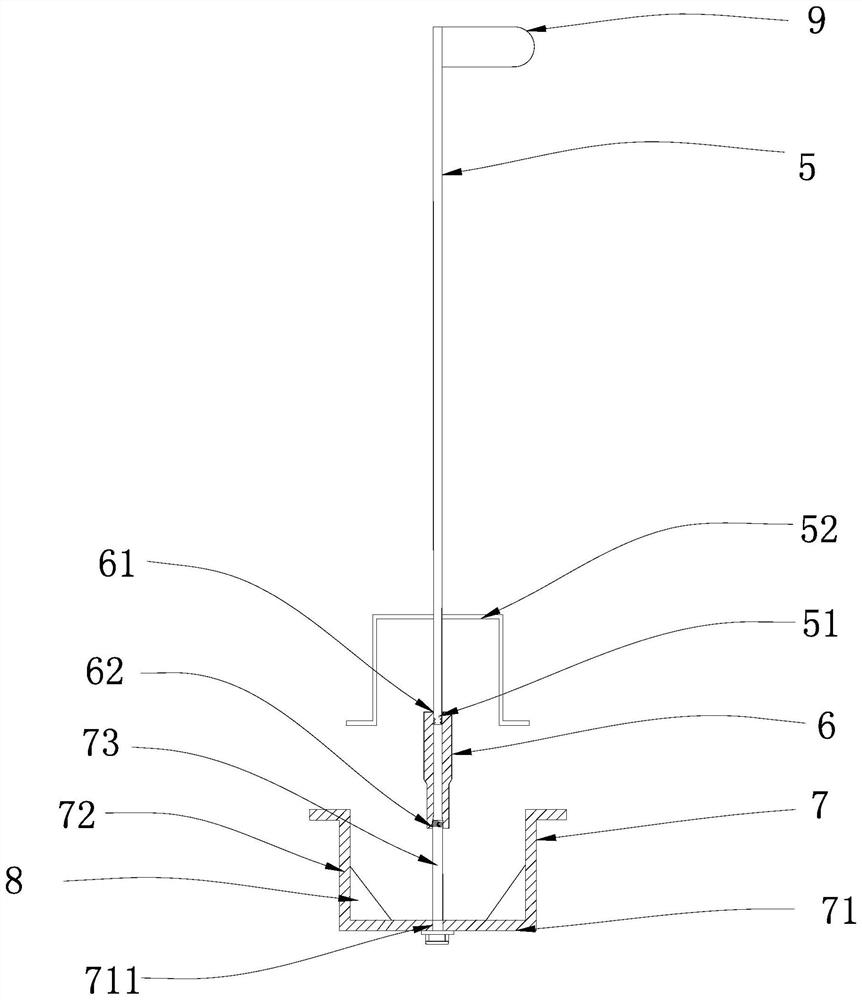

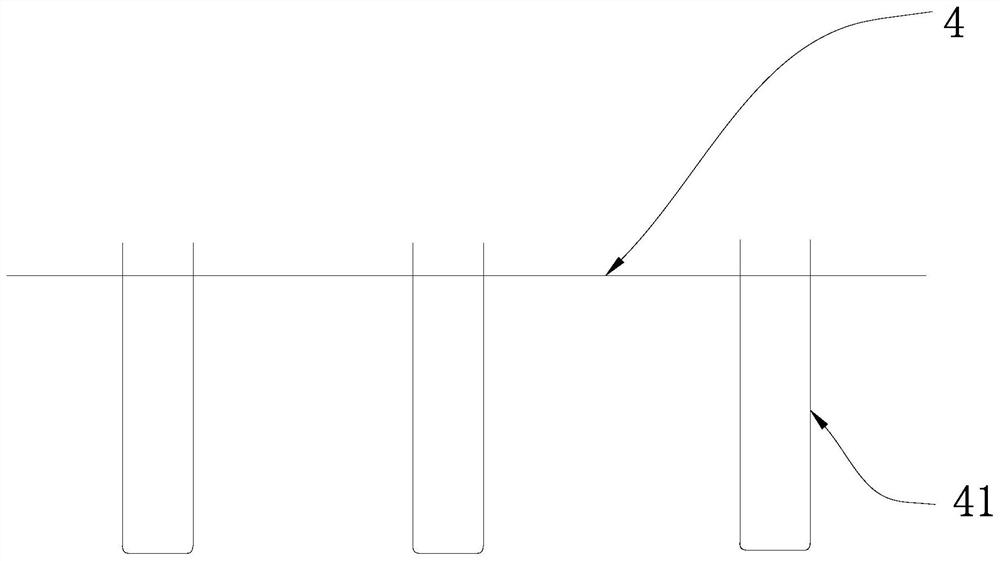

[0037] The present invention provides an anti-floating structure of a cast-in-situ concrete large-size mandrel 3 hollow floor, comprising a formwork 1 and a bracket 2 for supporting the formwork 1, above the formwork 1 is provided with an upper reinforcement mesh 11 and a lower reinforcement mesh 12, Several mandrels 3 are arranged between the upper steel mesh 11 and the lower steel mesh 12, and several mandrels 3 are horizontally arranged on the lower steel mesh 12, and it is characterized in that: the upper steel mesh 11 and the core Anti-floating reinforcing bars 4 are arranged between the molds 3, and the anti-floating reinforcing bars 4 are placed flat on several mandrels 3. The anti-floating reinforcing bars 4, the upper layer of reinforcing bars 11 and the lower layer of reinforcing bars 12 are arranged in parallel with each other. A vertical rod 5 is arranged between the adjacent mandrels 3, and the vertical rod 5 and the anti-floating steel bar 4 are arranged perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com