Construction method of municipal soft soil subgrade

A construction method and technology of soft soil subgrade, applied in roads, roads, buildings, etc., can solve problems such as insufficient shear strength of soft soil subgrade, damage of road structure layer, collapse of road embankment, etc., so as to prevent settlement and subsidence and improve compactness Degree, improve the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

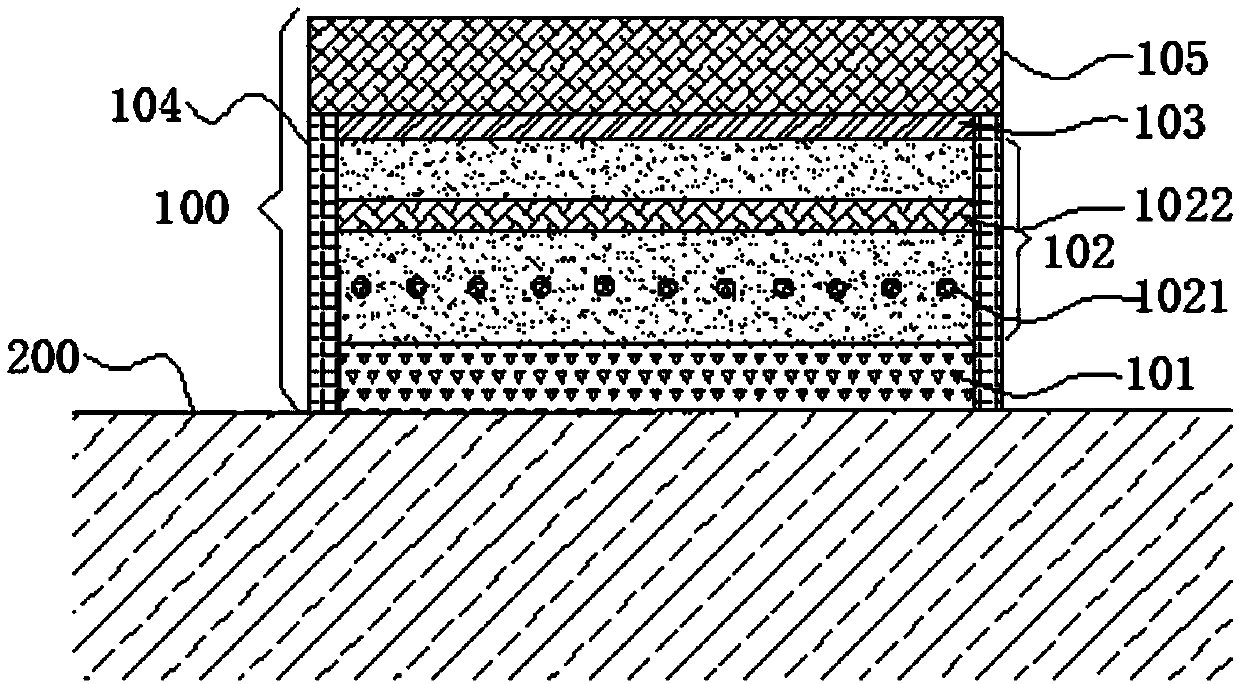

[0037] Embodiment: a kind of construction method of municipal soft soil subgrade, such as figure 1 As shown, the roadbed 100 includes a cement reinforcement layer 101, a cushion layer 102, a reinforcement layer 103, and a top seal layer 105 arranged in sequence from bottom to top, and also includes a retaining wall 104, which is located on the cement Both sides of the reinforcement layer 101, the cushion layer 102 and the reinforcement layer 103; the cushion layer 102 is provided with a layer of uniformly arranged longitudinal ribs 1021 and a layer of evenly arranged transverse ribs 1022;

[0038] Described construction method is carried out according to the following steps:

[0039] Step 1: Cleaning and removal of subgrade topsoil;

[0040] Step 2: Set drainage ditches on both sides along the roadbed direction at the bottom of the roadbed; set longitudinal and horizontal blind ditches at the base of the roadbed;

[0041] Step 3: Burying settlement and displacement observati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com