Suddenly applied load testing device

A load test and gravity loading technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inaccurate measurement of energy, inability to measure the dynamic characteristics and ultimate bearing capacity of specimens, and inaccurate measurement. The effect of avoiding impact on the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

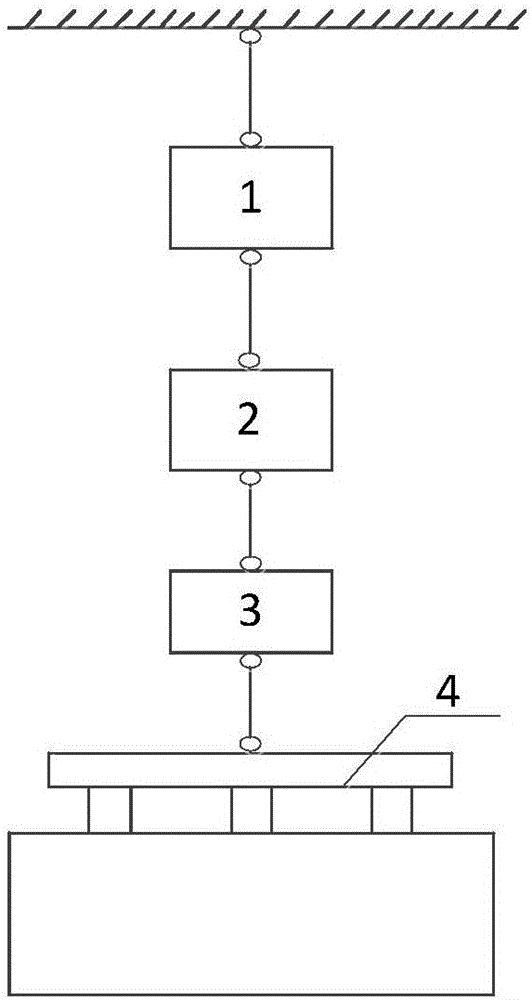

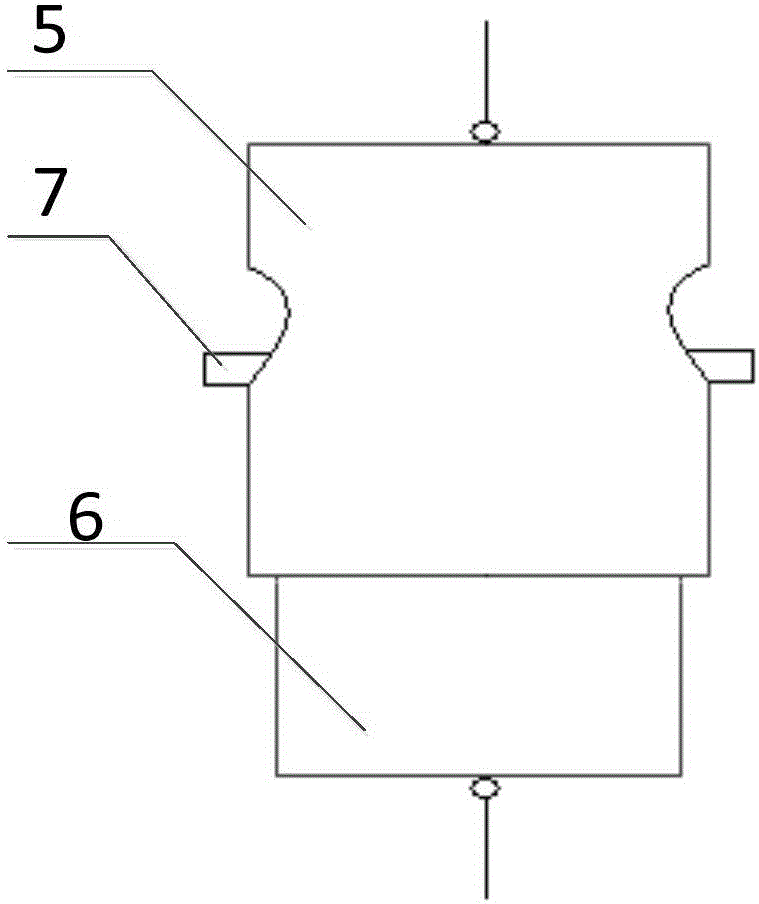

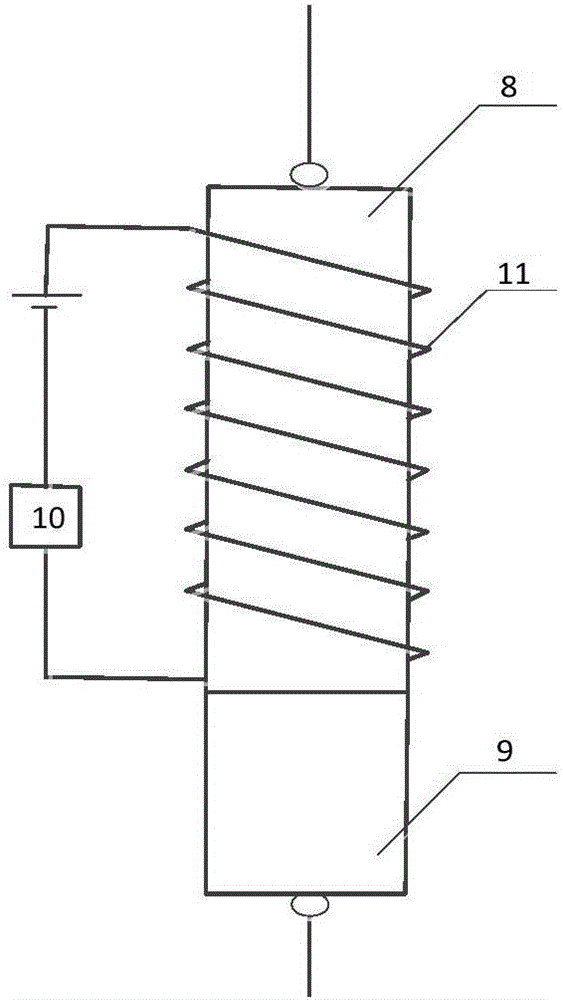

[0025] refer to figure 1 , the sudden load test device of the present invention comprises a support, a tension sensor 2, a cable force regulating device 1, a cable breaking device 3, a gravity loading device 4 and a controller, wherein the upper end of the cable force regulating device 1 is connected to the top of the support The output end of the cable force adjusting device 1 is connected to the upper end of the tension sensor 2 through a rope, the lower end of the tension sensor 2 is connected to the upper end of the cable breaking device 3, and the lower end of the cable breaking device 3 is connected to the upper end of the gravity loading device 4. The lower end surface of the gravity loading device 4 is in contact with the upper surface of the test piece, wherein the output end of the tension sensor 2 is connected to the input end of the controller, and the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com