A kind of automatic cleaning equipment with tank structure

A technology for cleaning equipment and storage tanks, which is used in the cleaning and cleaning of slender tank structures, and in the field of automated cleaning equipment, which can solve the problems of unguaranteed quality and low cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

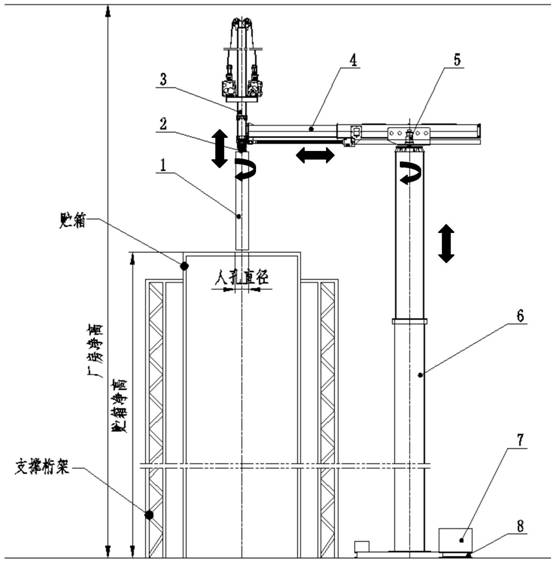

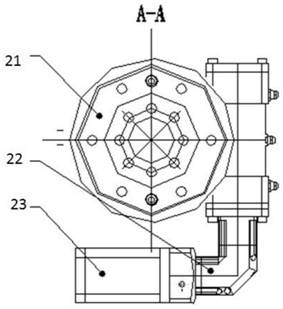

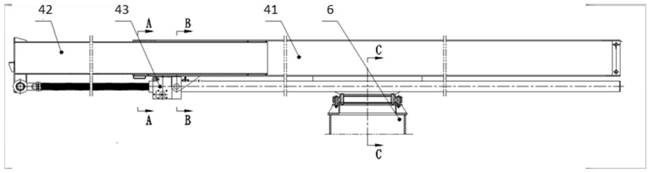

[0042] Combine figure 1 To explain this embodiment, an automatic cleaning equipment with a tank structure of this embodiment includes a cleaning head 1, a rotation mechanism 2, a feeding mechanism 3, a horizontal telescopic mechanism 4, a revolving mechanism 5, and a vertical telescopic mechanism. 6, the bottom frame 8; Among them: the vertical telescopic mechanism 6 is fixed above the bottom frame 8; the telescopic end of the vertical telescopic mechanism 6 is fixed with a slewing mechanism 5; the top of the slewing mechanism 5 is fixed with a horizontal telescopic mechanism 4 for driving horizontal telescopic The mechanism 4 makes a 360° rotation in a horizontal plane; the telescopic end of the horizontal telescopic mechanism 4 is connected with the feeding mechanism 3; the telescopic end of the feeding mechanism 3 is connected with the rotation mechanism 2 for driving the rotation mechanism 2 to reciprocate in the vertical direction ; The bottom end of the rotation mechanism ...

Embodiment approach 2

[0055] On the basis of the first embodiment, this embodiment further defines the structure of the feeding mechanism 3. In this embodiment, the feeding mechanism 3 includes a hoist 31, a wire rope 32, a pulley 33 and a feeding telescopic arm device 34; The telescopic arm device 34 is a telescopic sleeve structure composed of n-section feed arms, where: n≥2, the feed arm at the outermost layer is the basic feed arm 341, and the feed arm at the innermost layer is the feed n-section arm; hoist 31 is fixed on the side wall of the basic feed arm 341; pulley 33 is fixed at the top of the basic feed arm 341; one end of the wire rope 32 is wound on the driving wheel of the hoist 31, and the other end goes around the pulley 33 and the The feed n-section arms are connected; the hoist 31 pulls the wire rope 32 to drive the feed n-section arms to reciprocate in the vertical direction.

[0056] The feeding mechanism 3 in this embodiment realizes feeding in the height direction of the cleaning ...

Embodiment approach 3

[0061] On the basis of the second embodiment, this embodiment adds the technical feature "in the n-section feed arm, a guide wheel is arranged between two adjacent sections of the feed arm", such as Figure 4-6 As shown, in the n-section feed arm with the added technical feature of this embodiment, a guide wheel is arranged between two adjacent feed arms. The sliding friction slider of the traditional telescopic arm is changed to a guide wheel with rolling friction. It reduces the resistance of each section arm falling, reduces friction, saves energy, and can also achieve the effect of extending service life and reducing costs, and can also overcome the sliding friction of the traditional telescopic arm. The problem of poor stability of the telescopic arm caused by damage, this embodiment adopts a rolling friction guide wheel to make the telescopic arm have better stability performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com