GIS shell defect detection method based on magnetostriction torsional guided waves

A magnetostriction and defect detection technology, which is applied to the magnetic variables of materials, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as the inability to detect the part of the shell through the wall, limited ray detection effect, and poor detection effect. Realize online monitoring and continuous tracking, improve detection effect, and fast live detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

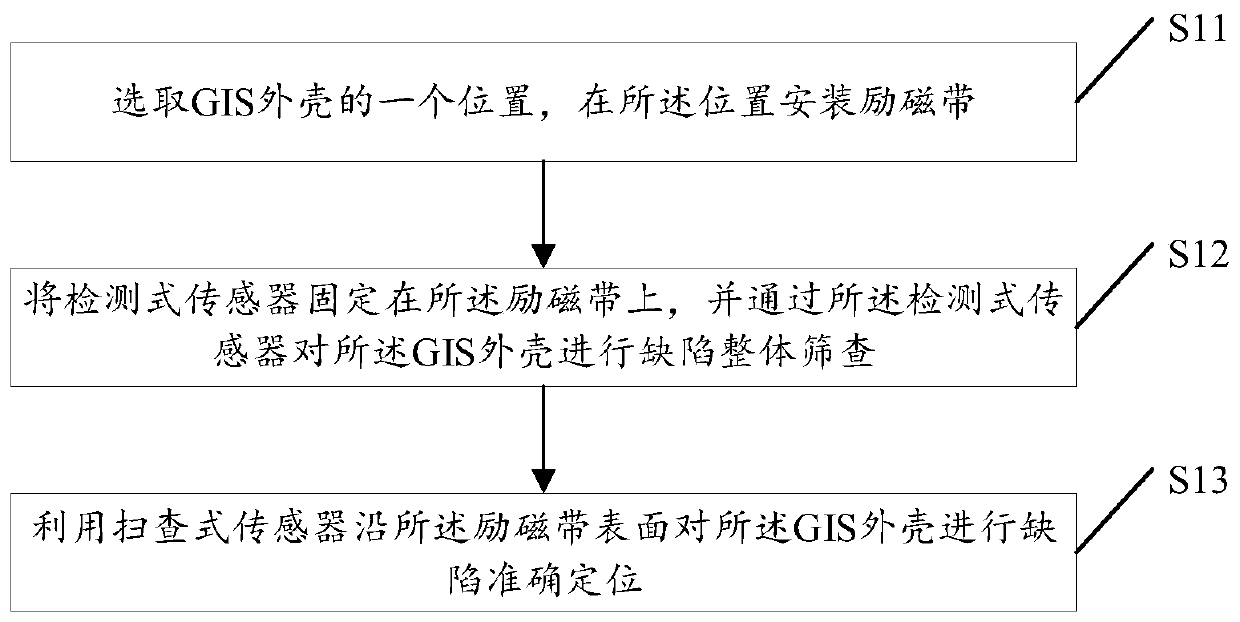

[0039] See figure 1 , figure 1 It is a schematic flow diagram of a method for detecting defects in a GIS shell based on a magnetostrictive torsion guided wave in an embodiment of the present invention.

[0040] Such as figure 1 As shown, a method for detecting GIS shell defects based on magnetostrictive torsion guided waves, the method includes:

[0041] S11: Select a position of the GIS shell, and install the excitation tape at the position;

[0042] In the specific implementation process of the present invention, selecting a position of the GIS housing and installing the excitation tape at the position includes: cutting the excitation tape with the circumference of the GIS housing and the width of the first preset value, and placing One side of the excitation tape is coated with a couplant with a thickness of a second preset value to obtain an excitation tape with a couplant; a position of the GIS housing is selected, and the excitation tape with a couplant is placed around the pos...

Embodiment 2

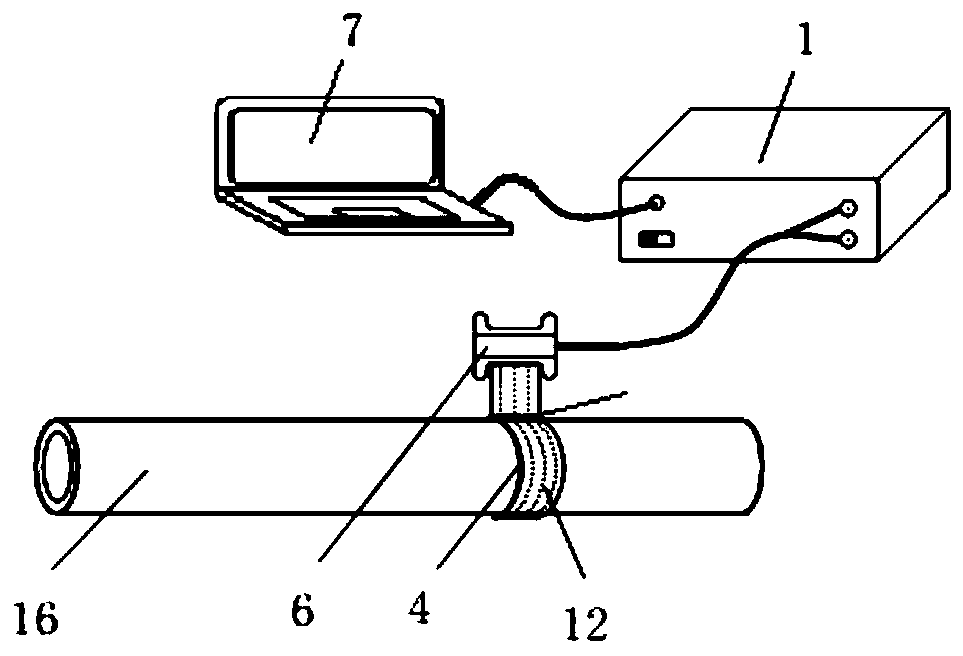

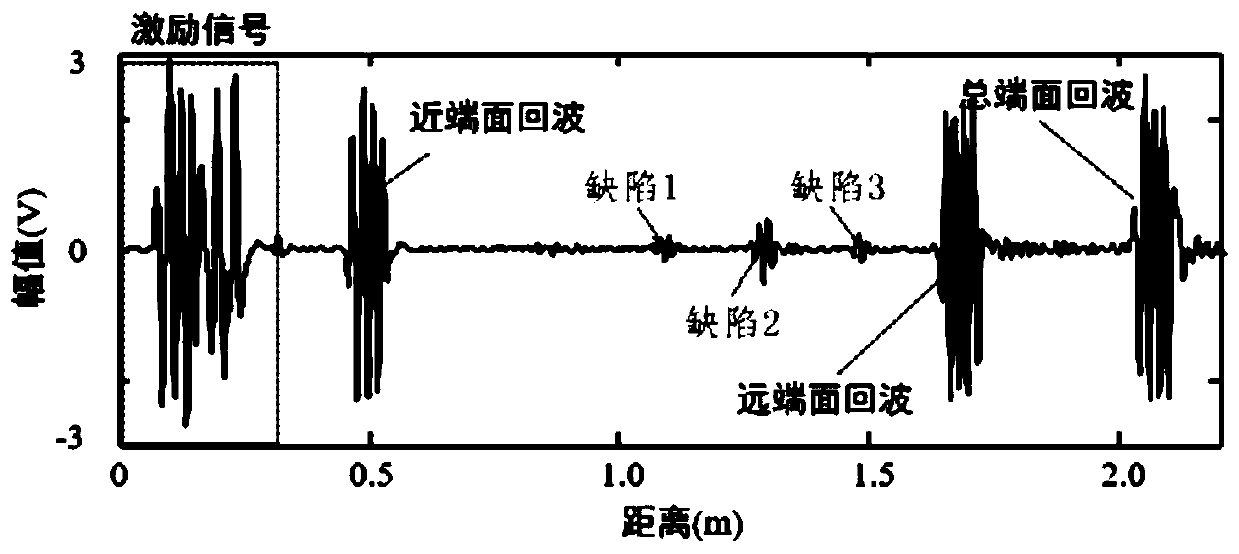

[0058] figure 2 Is a working schematic diagram of the detection sensor in the embodiment of the present invention; image 3 Is a schematic diagram of an A-scan image in an embodiment of the present invention; Figure 4 Is a working schematic diagram of the scanning sensor in the embodiment of the present invention; Figure 5 It is a schematic diagram of the C scan in the embodiment of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com