Vertical movement platform with horizontal bearing capacity

A technology of bearing capacity and vertical movement, which is applied in the field of vertical movement platform and large-stroke movement platform, can solve the problem of weak lateral load capacity and achieve the effect of protecting the screw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

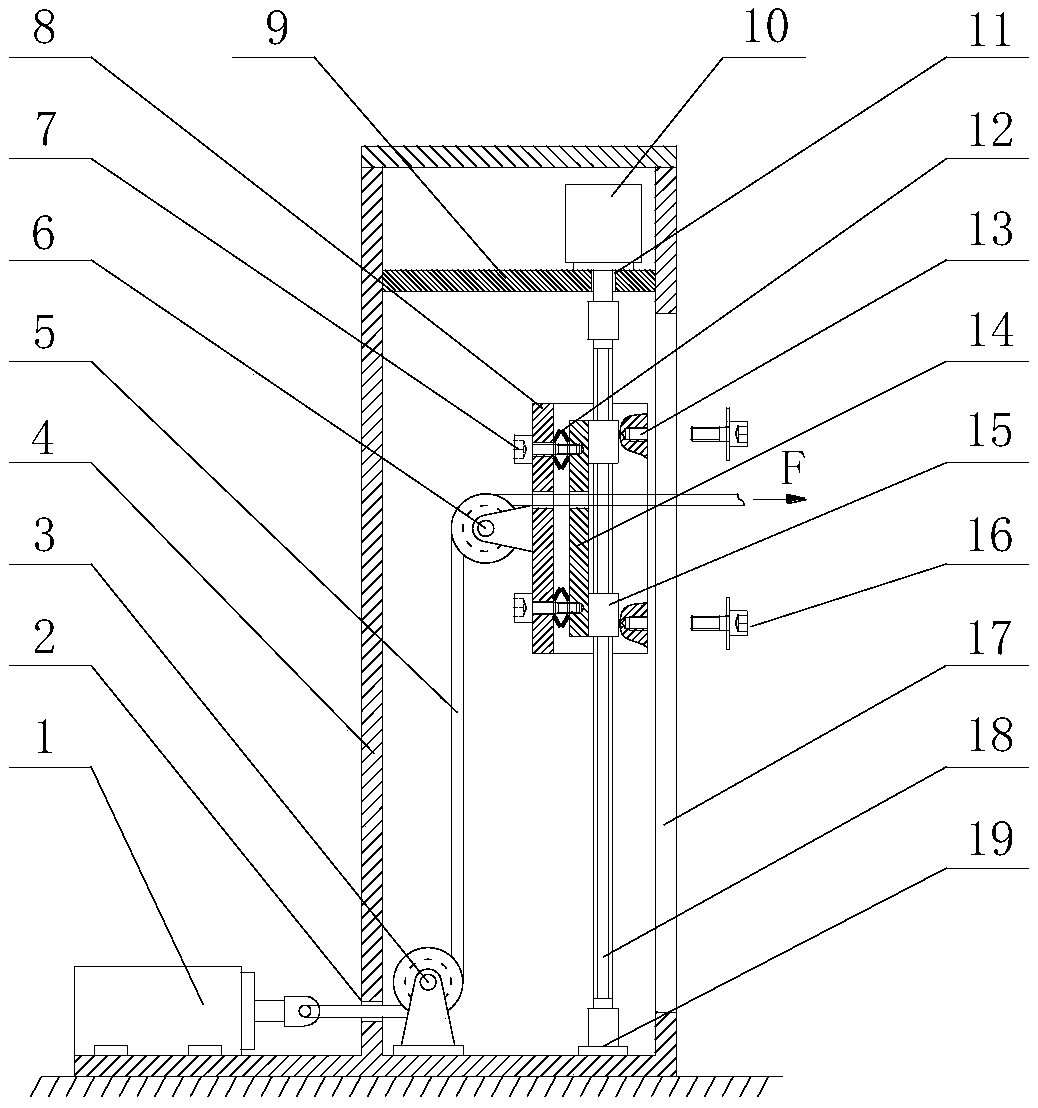

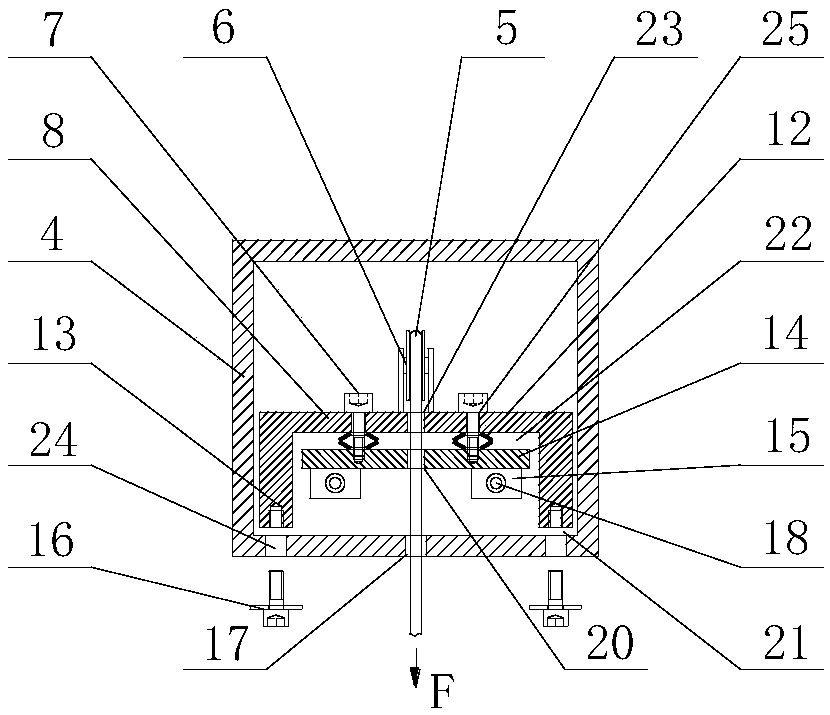

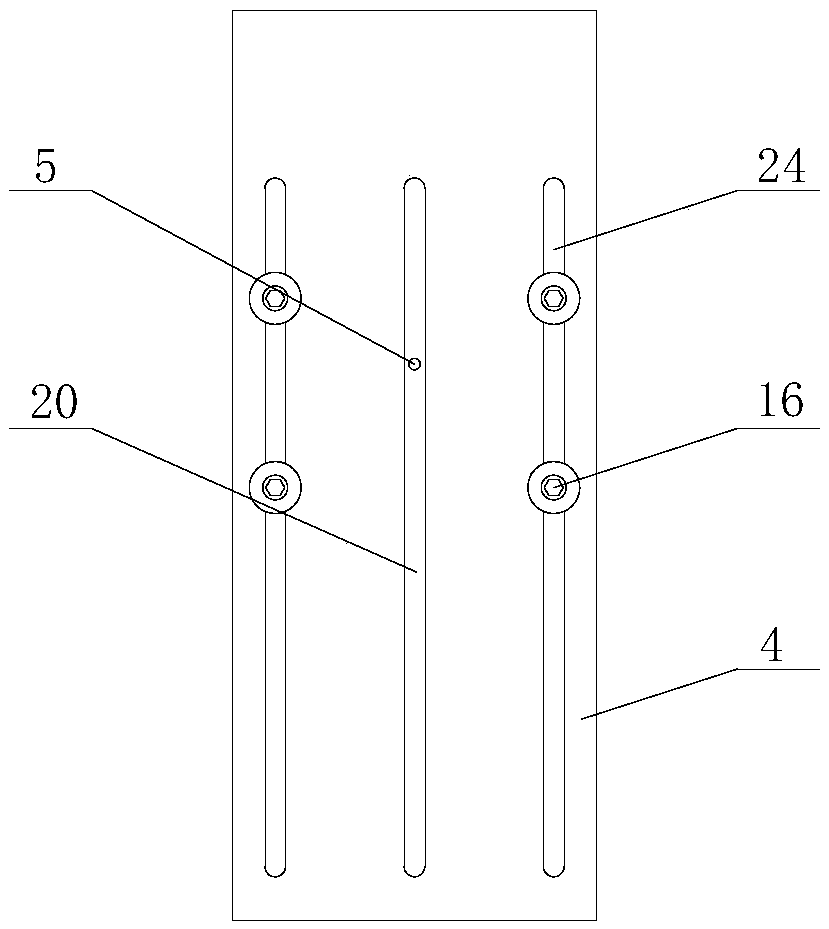

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0027] Aiming at the disadvantage that the motion table cannot bear large lateral force, the present invention proposes a vertical motion platform with lateral bearing capacity. The motion platform drives a screw and a slider through a motor, which can realize the spatial automatic positioning of the output position of the loading force. In addition, the platform is equipped with an active gap and a passive gap. When positioned at any position, the positioning bolts generate a pre-tightening force, which will cause the deformation of the spring, thereby reducing the passive gap until the pulley seat is in close contact with the load-bearing frame, that is, the load-bearing is realized. The frame bears the external force, avoiding the lateral force on the lead screw. After the pre-tightening force is released, the automatic control of the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com