Pressure head capable of reducing lateral bending risk for upward bending supplement straightening of end part of steel rail

A rail and indenter technology, applied in the metallurgical field, can solve the problems of rail side bending and increased side bending, and achieve the effects of reducing damage to the rail, avoiding lateral force components, and reducing the risk of side bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

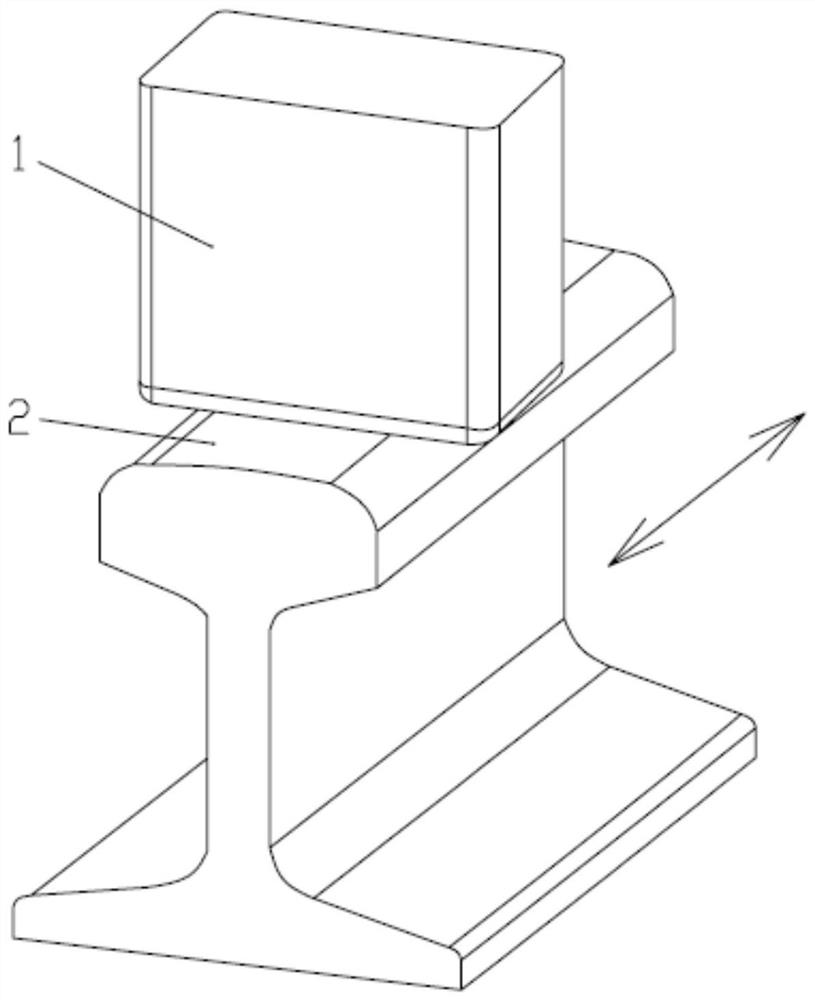

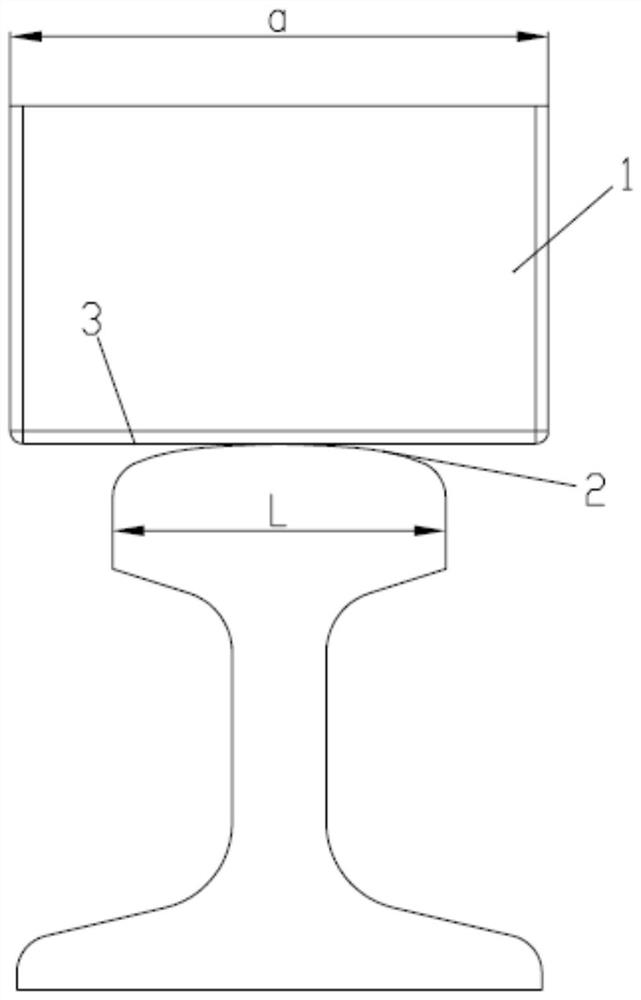

[0031] Take the supplementary straightening of 60kg / m U71Mn high-speed rail as an example:

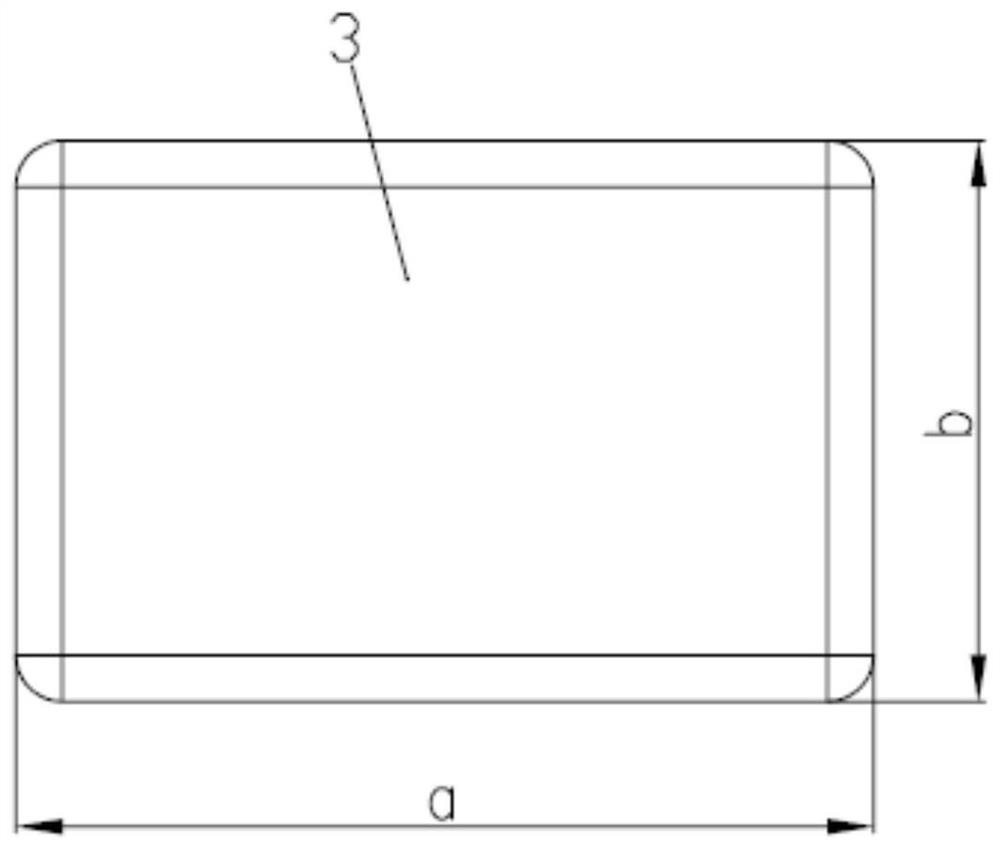

[0032] A. The rail head width L of 60kg / m U71Mn high-speed rail is 73mm, and the maximum arc of the top surface is R300mm. According to the relationship between the long side a of the indenter and the width L of the rail head for supplementary straightening, the long side a is 1.2 times the width L of the rail head, that is, the long side a is 87.6mm;

[0033] B. According to the determination principle of the short side b, take the short side b of the indenter as 200mm;

[0034] C. In order to prevent the edges and corners on the indenter from damaging the top surface of the rail when it contacts the arc-shaped tread of the rail head during the supplementary straightening process, the edges and corners corresponding to the long sides a on both sides of the indenter are set as circular arc chamfering structures. The radius is 3mm; the other corners can also be chamfered.

[0035] D. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com