High-pressure rotary spraying and core inserting process to form pedestal pile

A technology of high-pressure rotary spraying and bottom-expanding piles, which is applied to sheet pile walls, buildings, and foundation structure engineering, and can solve the problem of low ratio between bearing capacity and price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

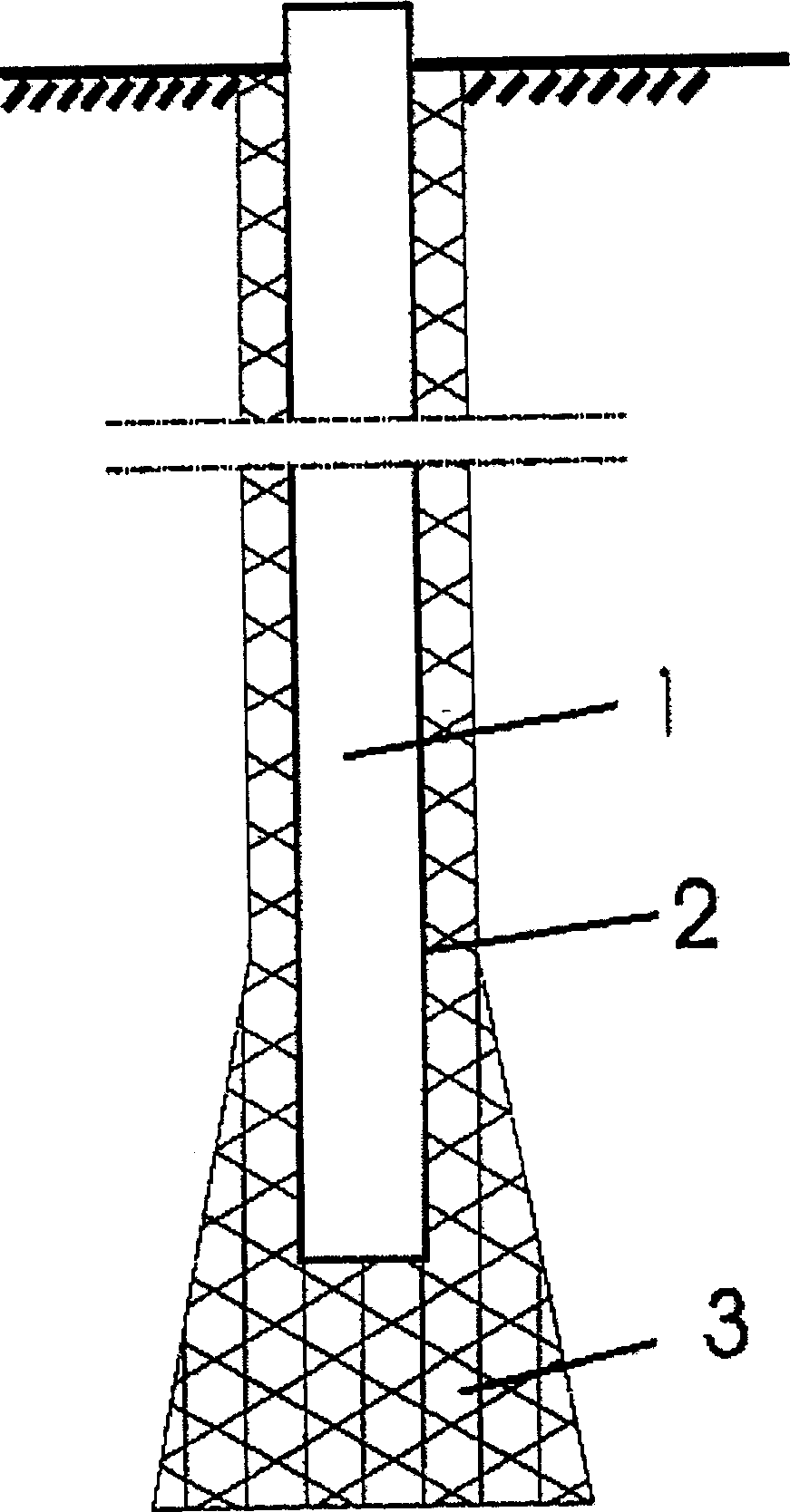

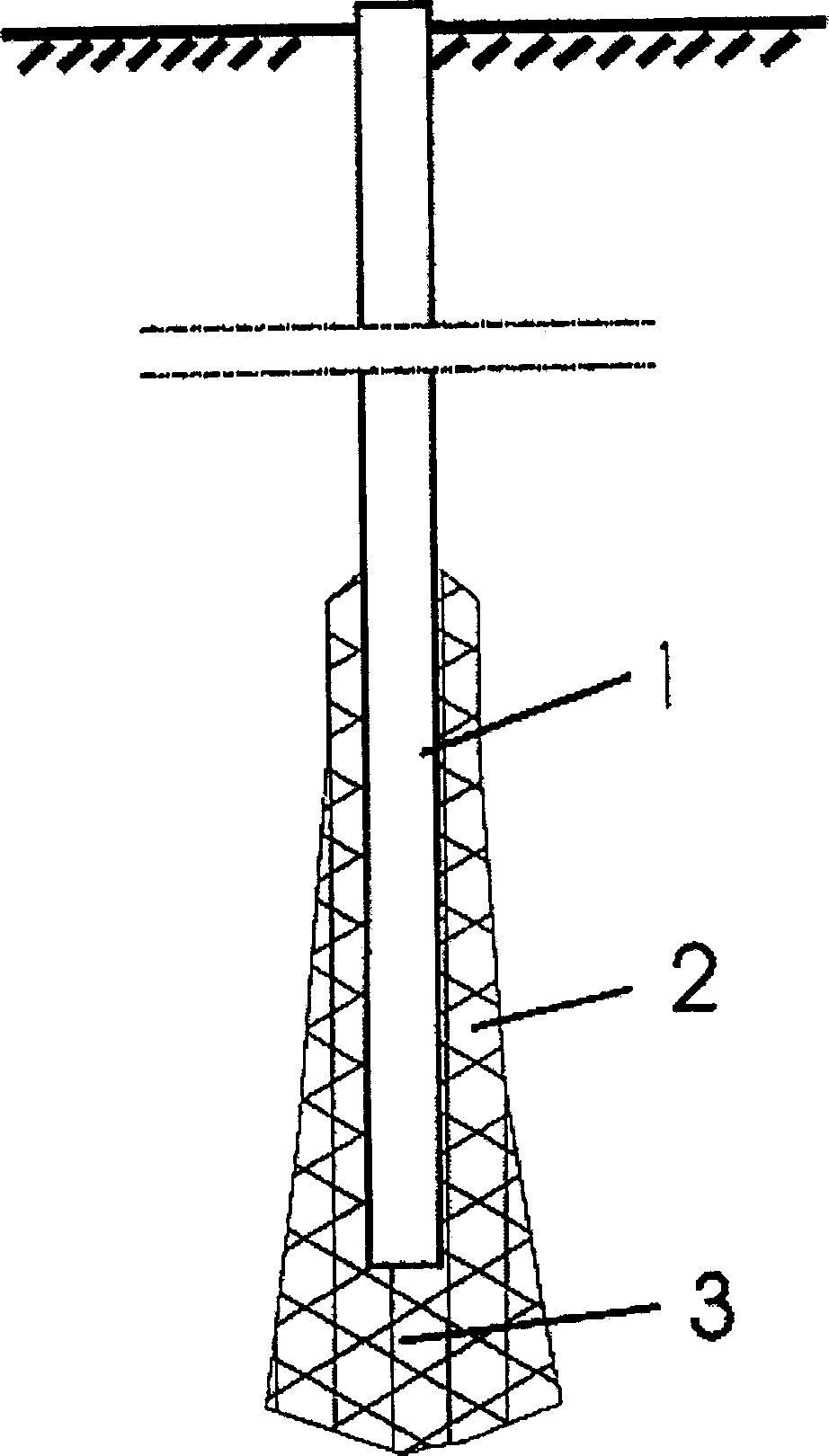

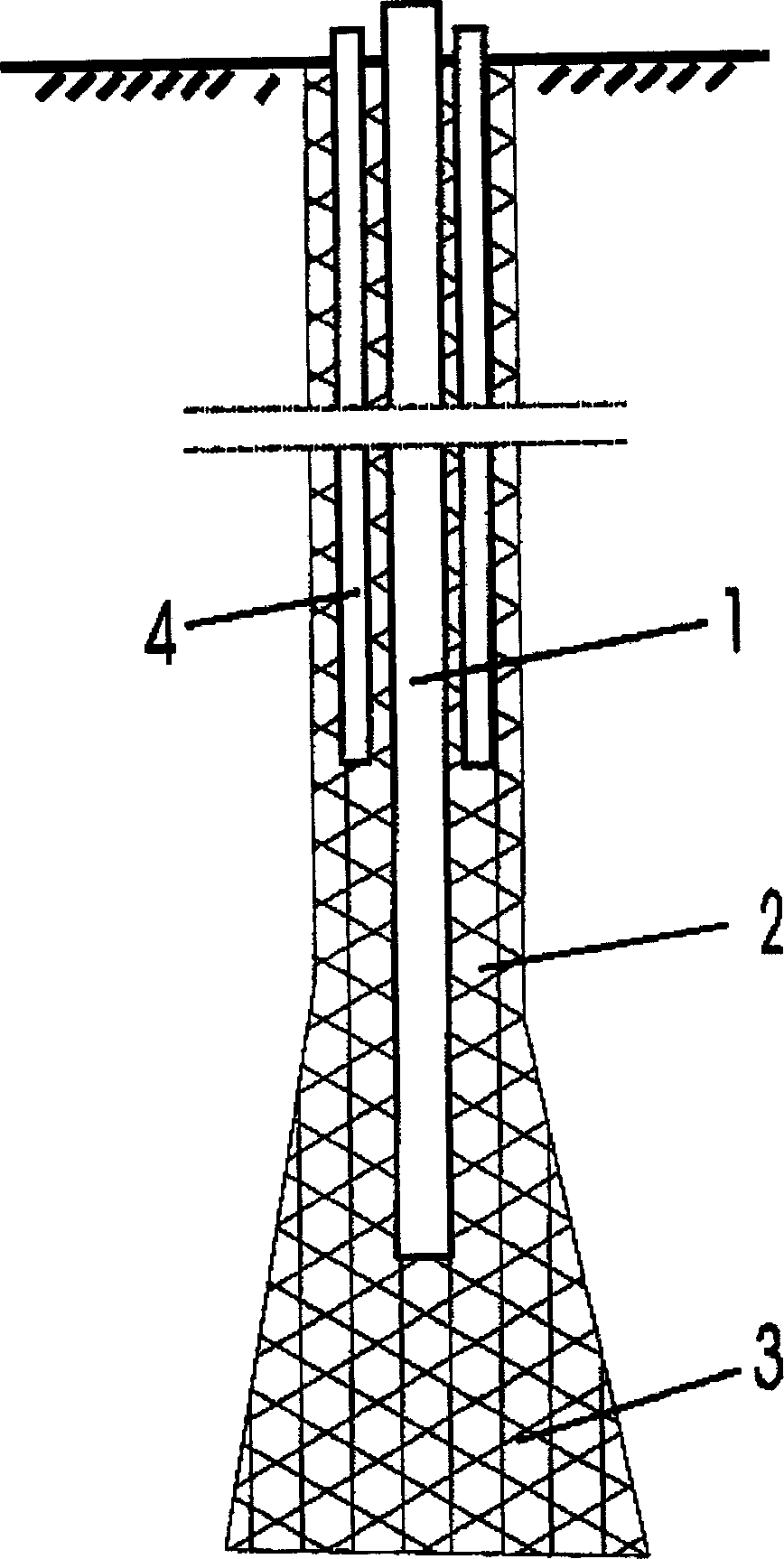

Embodiment 1

[0038] It consists of a core pile (1), a pile body (2) and a pile bottom (3). The core pile (1) is cylindrical, and the core pile (1) is a reinforced concrete prefabricated pile with a square cross section. The pile body (2) is arranged relatively parallel to the surface of the core pile (1), the pile body (2) wraps the core pile (1), the lower end of the core pile (1) is the pile bottom (3), and the diameter of the pile bottom (3) It is larger than the core pile (1), and the section of the pile body (2) is circular, such as figure 1 , figure 2 , Figure 6 , Figure 7 , Figure 8 , Figure 11 , Figure 12 , Figure 13 shown.

Embodiment 2

[0040] It consists of a core pile (1), a pile body (2) and a pile bottom (3). The core pile (1) is cylindrical, and the core pile (1) is a cast-in-place pile with a circular cross section. The pile body (2) is arranged relatively parallel to the surface of the core pile (1), the pile body (2) wraps the core pile (1), the lower end of the core pile (1) is the pile bottom (3), and the diameter of the pile bottom (3) It is larger than the core pile (1), and the section of the pile body (2) is fan-shaped, such as figure 1 , figure 2 , Figure 9 , Figure 11 , Figure 14 shown.

Embodiment 3

[0042] It consists of a core pile (1), a pile body (2) and a pile bottom (3). The core pile (1) is cylindrical, and the core pile (1) adopts a steel structure pile with an H-shaped section. The pile body (2) is arranged relatively parallel to the surface of the core pile (1), the pile body (2) wraps the core pile (1), the lower end of the core pile (1) is the pile bottom (3), and the diameter of the pile bottom (3) It is larger than the core pile (1), and the section of the pile body (2) is semicircular, such as figure 1 , figure 2 , Figure 8 , Figure 10 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com