High-pressure rotary-jetting hollow bottom-expanding pile and making method thereof

A technology of high-pressure rotary spraying and bottom-expanding piles, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of design and construction difficulty, cost of funds, and energy consumption, and achieve no mud discharge, fast construction, and reduced The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

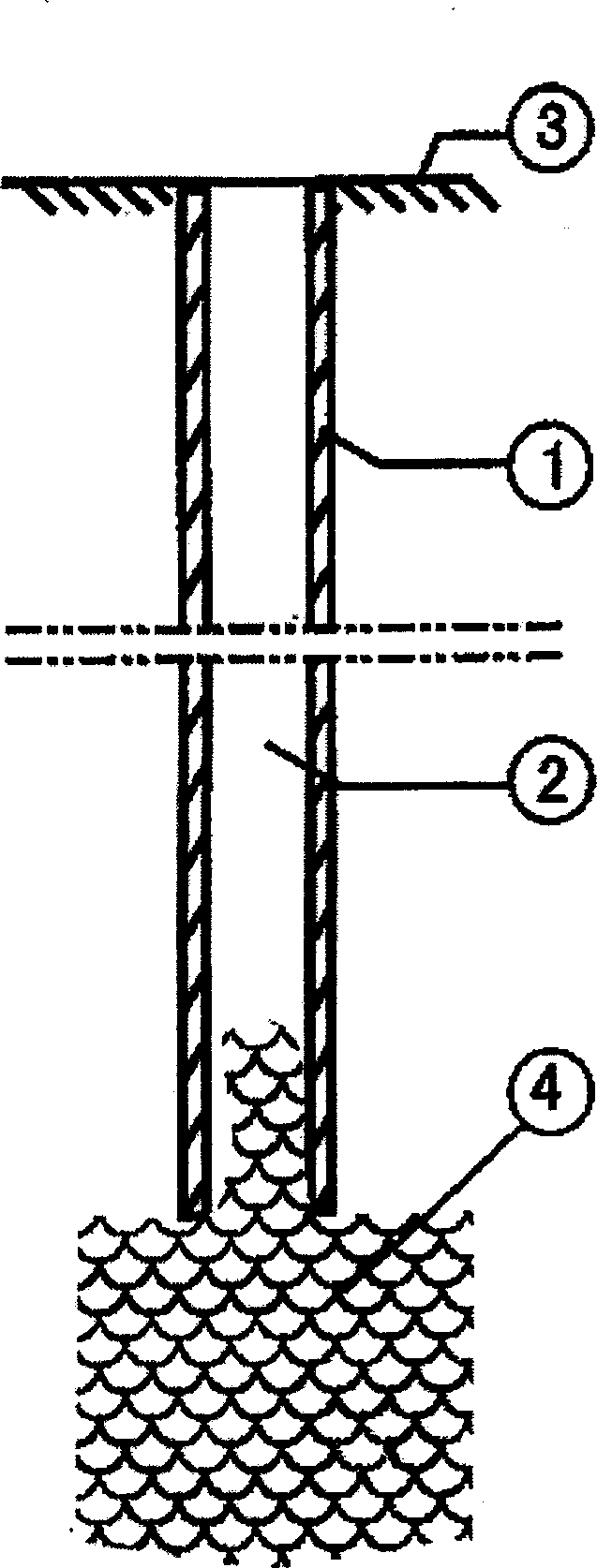

[0032] In the foundation (3), the pile body (1) is relatively parallel and vertically arranged along the foundation (3), and the middle part of the pile body (1) is relatively parallel to the pile body (1), and the hollow hole (2) is arranged, and the hollow hole (2) runs through the pile body (1). Bottom-expanding pile feet (4) are arranged at the lower end of the inner pile body (1) of the foundation (3).

[0033] The length of the pile body (1) is determined according to the design requirements, and the pile body (1) is relatively parallel and vertically placed in the foundation (3) by means of a vibrating hammer with a pile driver. A hollow hole (2) is arranged in the middle of the pile body (1), and the aperture diameter of the hollow hole (2) and the wall thickness of the pile body (1) are set according to design requirements. Bottom-enlarging pile feet (4) are set at the lower end of the pile body (1) to improve the bearing capacity of the pile body (1), such as figur...

Embodiment 2

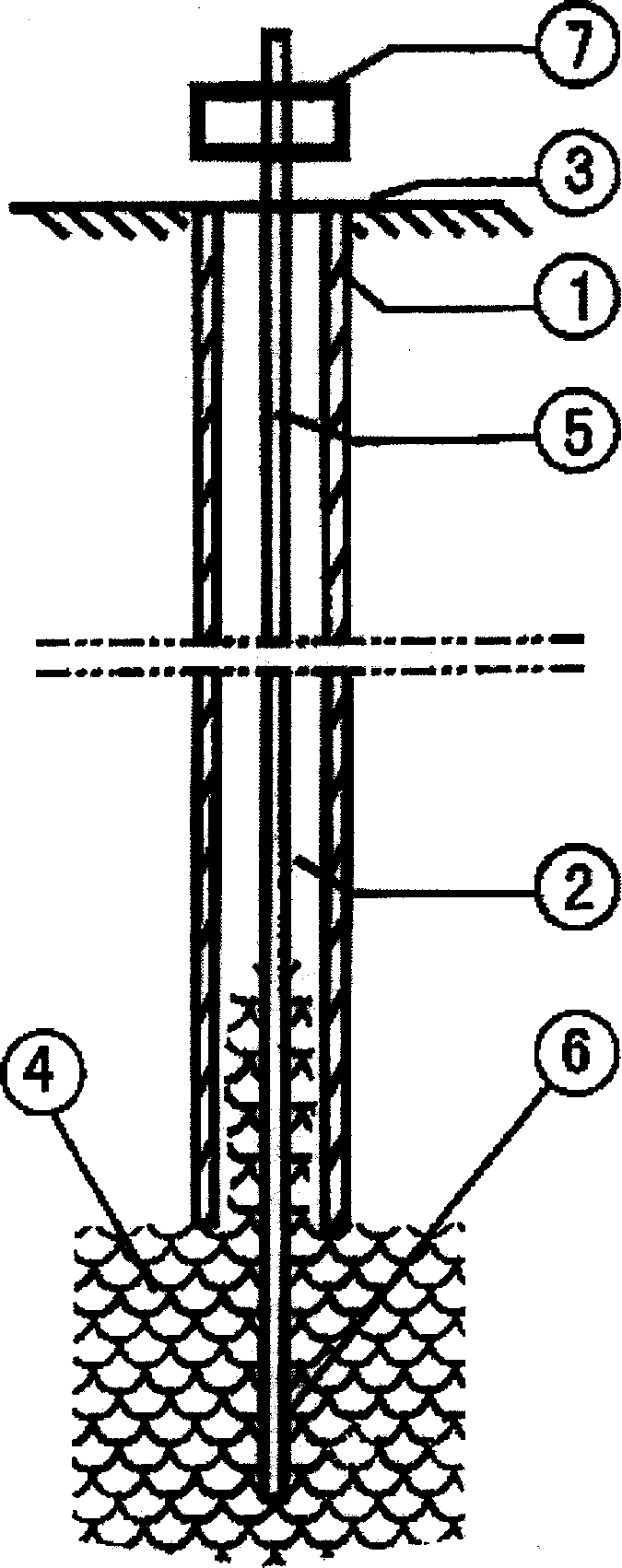

[0035] In the foundation (3), the pile body (1) is relatively parallel and vertically arranged along the foundation (3), and the middle part of the pile body (1) is relatively parallel to the pile body (1), and the hollow hole (2) is arranged, and the hollow hole (2) runs through the pile body (1). Bottom-expanding pile feet (4) are arranged at the lower end of the inner pile body (1) of the foundation (3).

[0036] The length of the pile body (1) is determined according to design requirements, and the pile body (1) is relatively parallel and vertically placed in the foundation (3) by a static pressure method using a pile driver. A hollow hole (2) is arranged in the middle of the pile body (1), and the aperture diameter of the hollow hole (2) and the wall thickness of the pile body (1) are set according to design requirements. Bottom-enlarging pile feet (4) are set at the lower end of the pile body (1) to improve the bearing capacity of the pile body (1), such as figure 1 , ...

Embodiment 3

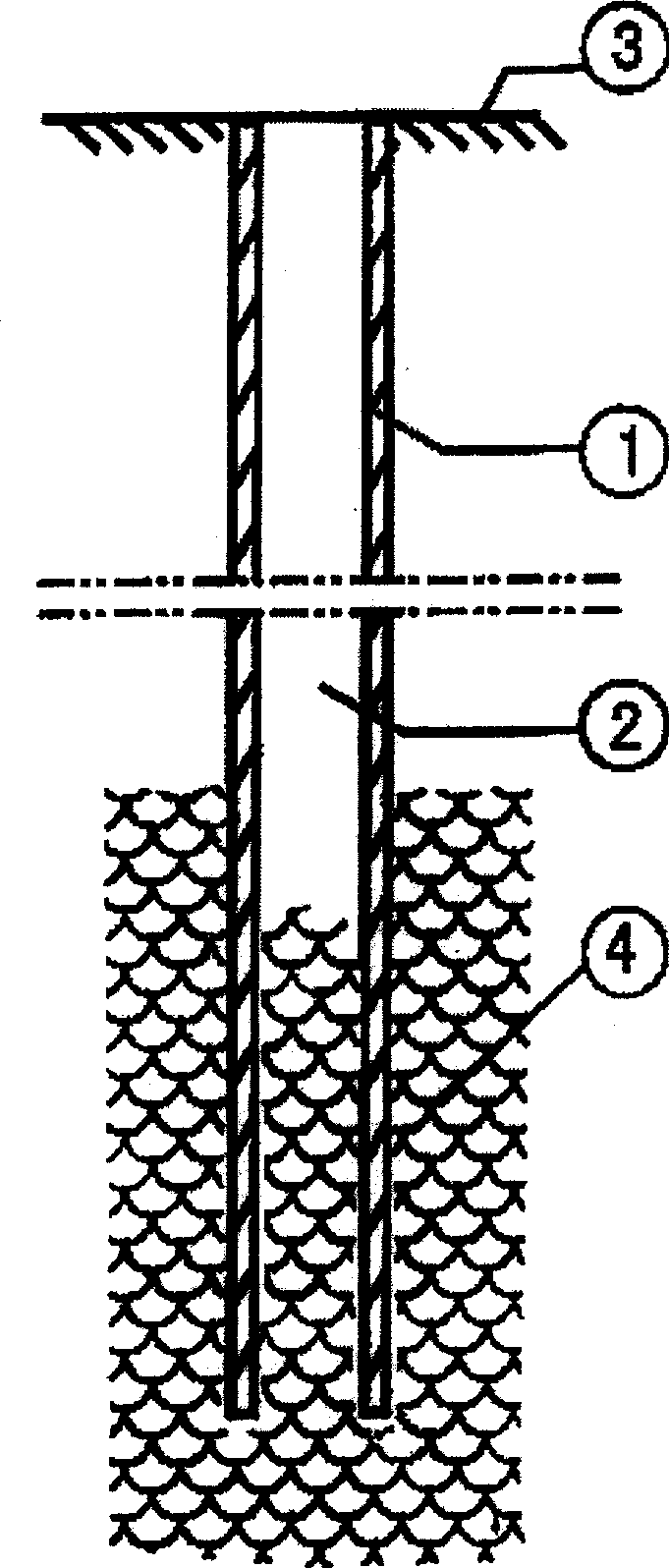

[0038] The diameter of the expanded bottom pile foot (4) is greater than the diameter of the section of the pile body (1), and the height of the expanded bottom pile foot (4) is greater than the diameter of the expanded bottom pile foot (4). One end of the bottom-expanding pile foot (4) is embedded in the hollow hole (2) of the pile body (1), so that the bottom-expanding pile foot (4) and the pile body (1) form an integral body.

[0039] At the lower end of the pile body (1), the expanded bottom pile foot (4) is set, and the diameter of the expanded bottom pile foot (4) should be greater than the diameter of the pile body (1), and the height of the enlarged bottom pile foot should be greater than the enlarged bottom pile foot. The diameter of the bottom pile foot (4) improves the load capacity of the pile body (1) and the friction force at the bottom of the pile body (1), such as figure 1 , figure 2 , image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com