Intelligent aluminum alloy bar concrete structure, and manufacturing and construction method thereof

A technology of concrete structure and manufacturing method, which is applied to bridge parts, erection/assembly of bridges, bridge maintenance, etc. It can solve problems such as bad social impact, inconvenient hoisting and transportation, and unclear stress on steel bars, so as to save reinforcement and maintenance costs , to achieve the effect of safety and health monitoring, hoisting and transportation convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

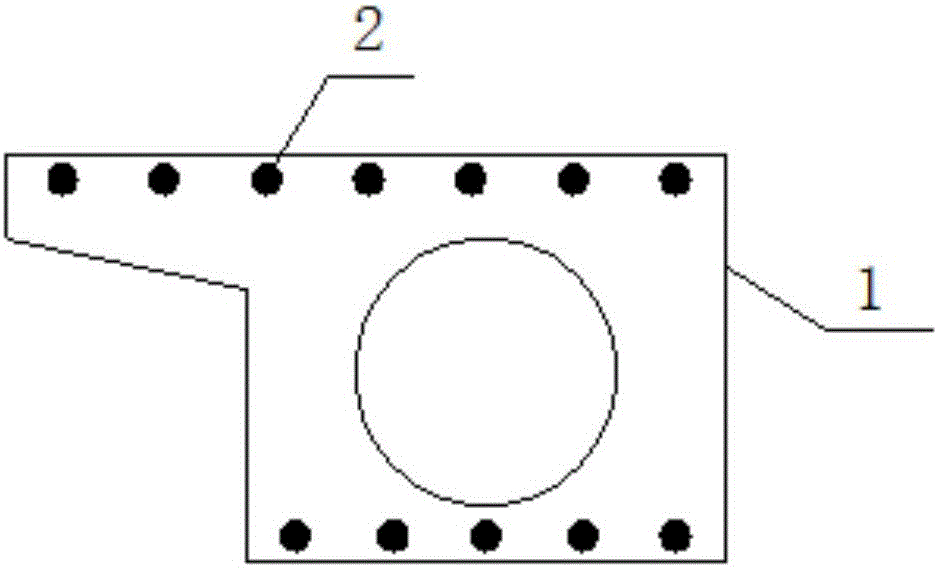

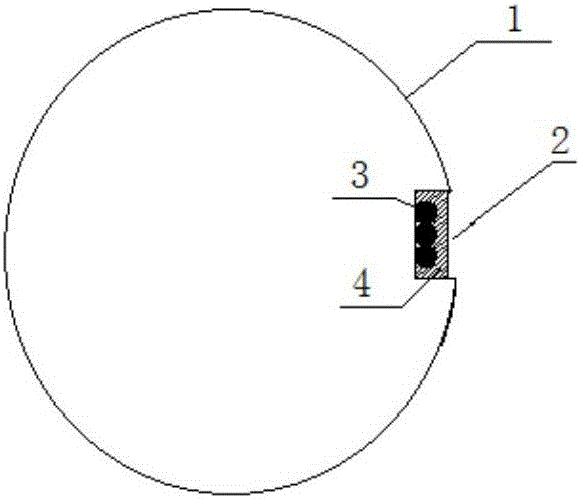

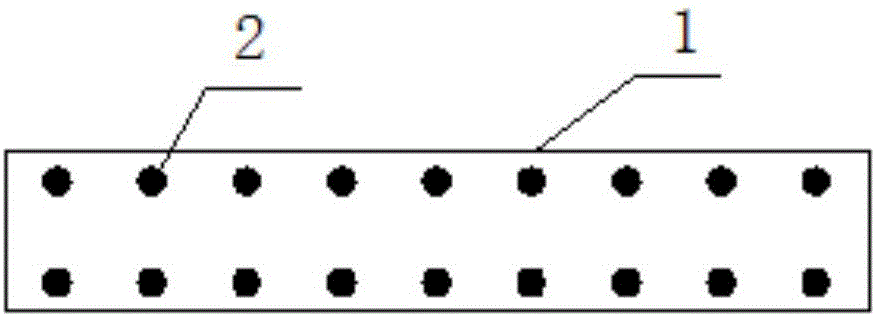

[0035] Such as figure 1 As shown in the figure, the smart aluminum alloy reinforced concrete beam structure, the concrete beam 1 uses smart aluminum alloy bars and ordinary aluminum alloy bars to form the skeleton 2. Its production and construction methods are as follows:

[0036] (1) Support formwork: process and install the formwork according to the design dimensions and requirements of the concrete beam structure;

[0037] (2) Binding skeleton: according to the stress characteristics of the aluminum alloy, the stress analysis and design of the structure, the reinforcement is made, and the intelligent aluminum alloy reinforcement is made, and then the skeleton is bound according to the designed construction drawings, in which the intelligent aluminum alloy reinforcement leaves the optical fiber Wiring of the grating sensor, and pooling;

[0038] (3) Pouring concrete: hoist the skeleton 2 into the formwork, pour concrete, and when vibrating the concrete, pay attention that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com