Construction method for pulling-resistant and pressure-resistant slip casting pipe pile

A construction method and technology of grouting pipes, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of insufficient pullout resistance of uplift piles, insufficient buoyancy resistance, and water seepage of the bottom plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

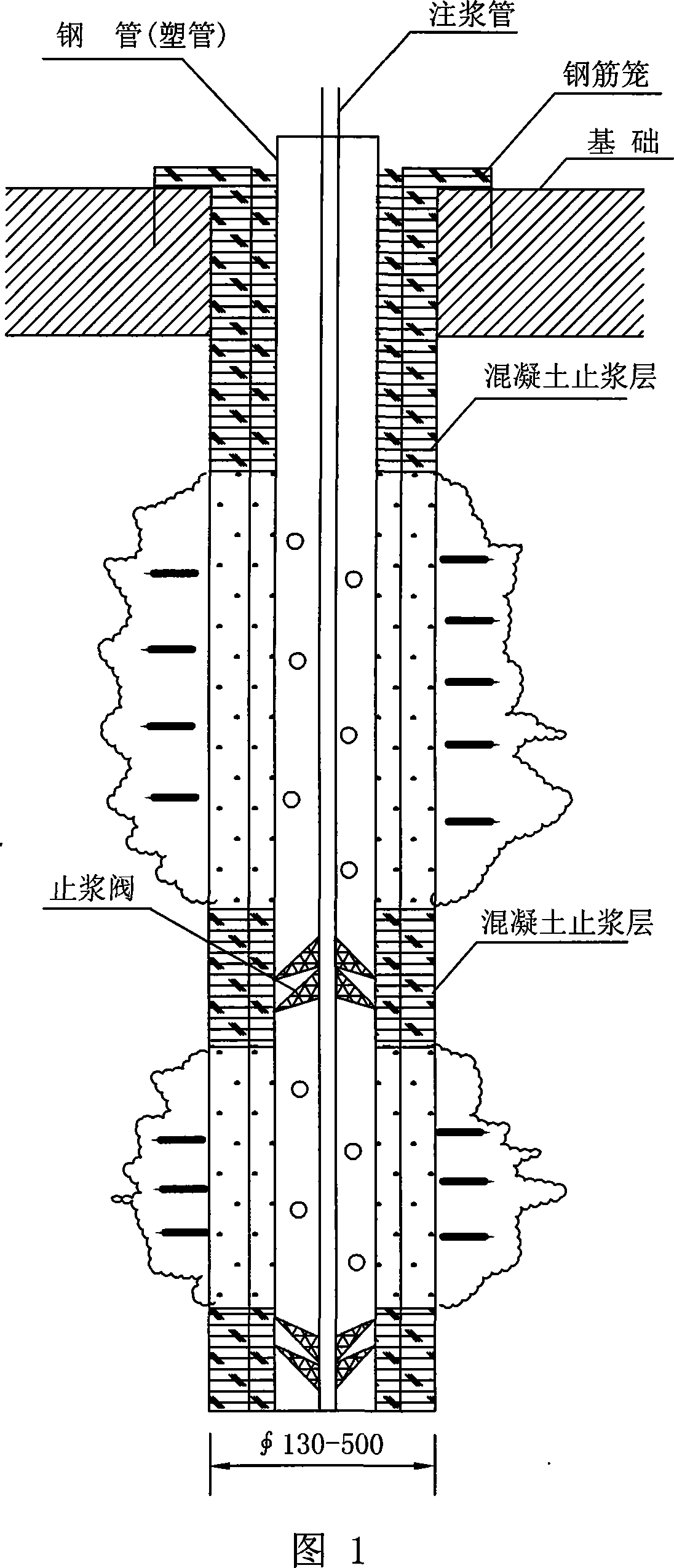

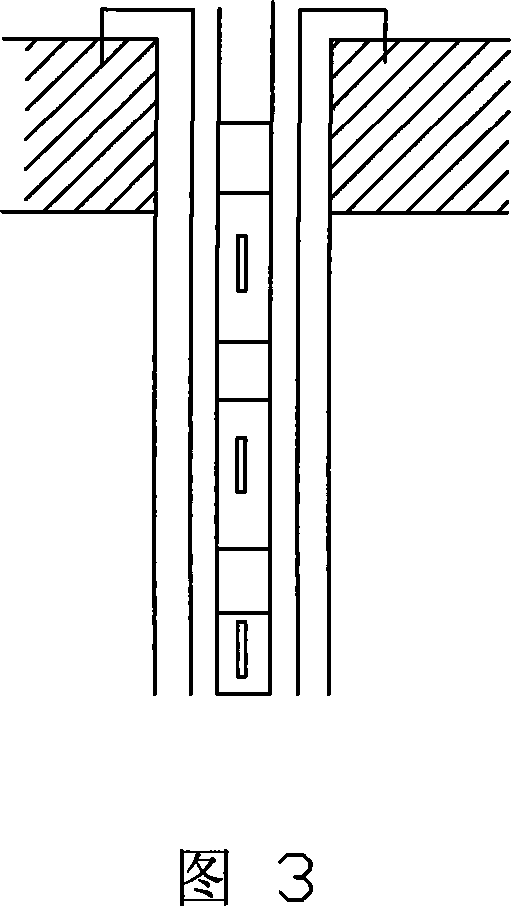

[0005] Specific embodiment one: (referring to Fig. 1~Fig. 6) the method of this embodiment is realized through the following steps: one, according to the design elevation of pile and aperture on the foundation layer of building, drill down; Put the steel pipe or plastic pipe with grouting hole into the hole, and the position of the steel pipe or plastic pipe is centered in the hole; 3. Put the steel bar or steel cage into the hole outside the steel pipe or plastic pipe; Put sand or gravel into the space between the outer wall of the plastic pipe and the hole wall; 5. Put a grouting pipe with a grout stop valve into the steel pipe or plastic pipe; 6. Start the grouting pump and start grouting into the pile hole 7. Effective (welding) connection between the steel pipe or the plastic pipe and the steel bar or steel cage and the base layer of the building after the pile is completed and the waterproof treatment of the pile sealing.

specific Embodiment approach 2

[0006] Embodiment 2: In this embodiment, the diameter Φ of the steel pipe or plastic pipe is 50-150 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Embodiment 3: In this embodiment, hoops are fixed on the outer wall of the steel pipe or plastic pipe, and the distance between the hoops is 50 cm. A hoop is fixed on the outer wall of the steel pipe or the plastic pipe to improve the frictional force with the concrete of the pile body. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com