Shear part of spiral spring bolt and construction method

A technology of helical springs and shear parts, which is applied to bridge parts, erection/assembly of bridges, bridge maintenance, etc. It can solve the problems of low construction efficiency, weak pull-out resistance, low shear strength and stiffness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

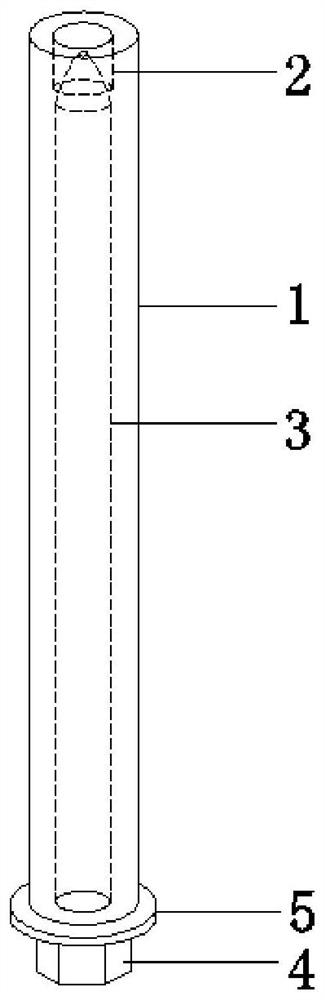

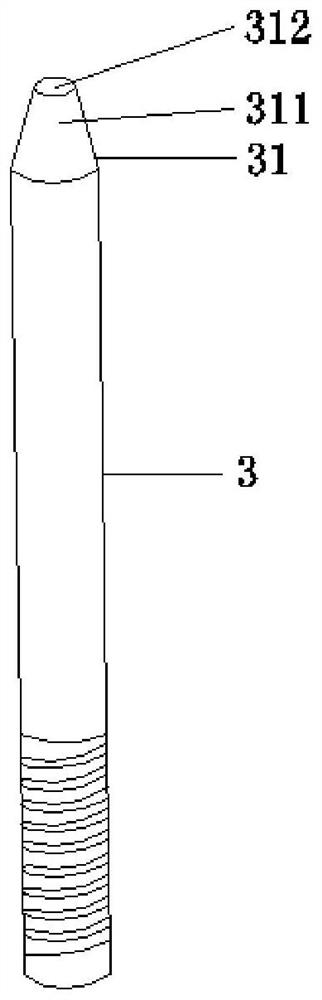

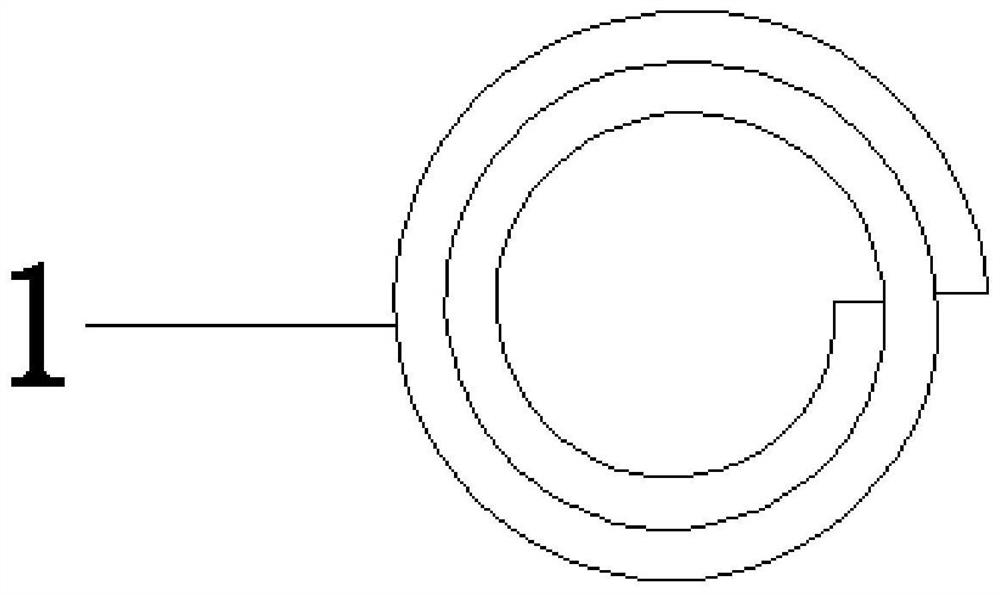

[0031] Such as Figures 1 to 5 As shown, a shear member of a helical spring bolt includes an elastic sleeve 1, an elastic nut 2, a screw 3 and a nut 4, and the elastic sleeve 1 is sleeved on the screw 3 and the elastic nut 2, and the One end of the elastic nut 2 abuts against the top of the elastic sleeve 1, the other end of the elastic nut 2 abuts against one end of the screw 3, the elastic nut 2 applies a reaction force to the screw 3, and the other end of the screw 3 Threaded connection with the nut 4, the nut 4 applies force to the screw rod 3, the end of the screw rod 3 and the elastic nut 2 is tapered, the elastic sleeve 1 includes an elasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com