Rectangular concrete piles for building side walls of pipe gallery

A technology of concrete piles and rectangles, applied in buildings, sheet pile walls, underwater structures, etc., can solve the problems of pipe gallery settlement, high engineering cost, and long construction period, so as to reduce excavation and reduce adverse effects , The effect of reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

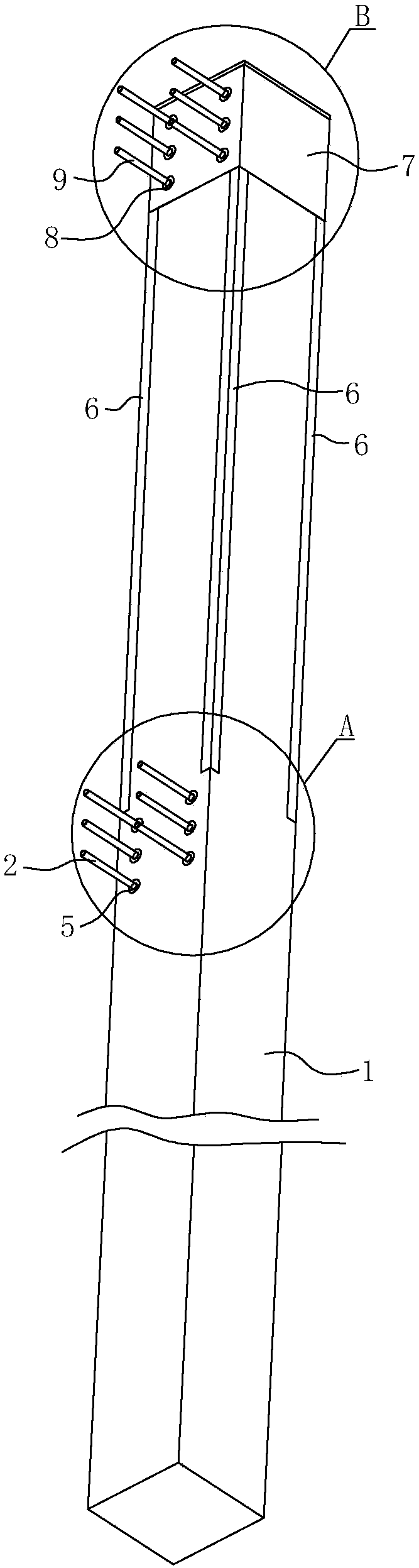

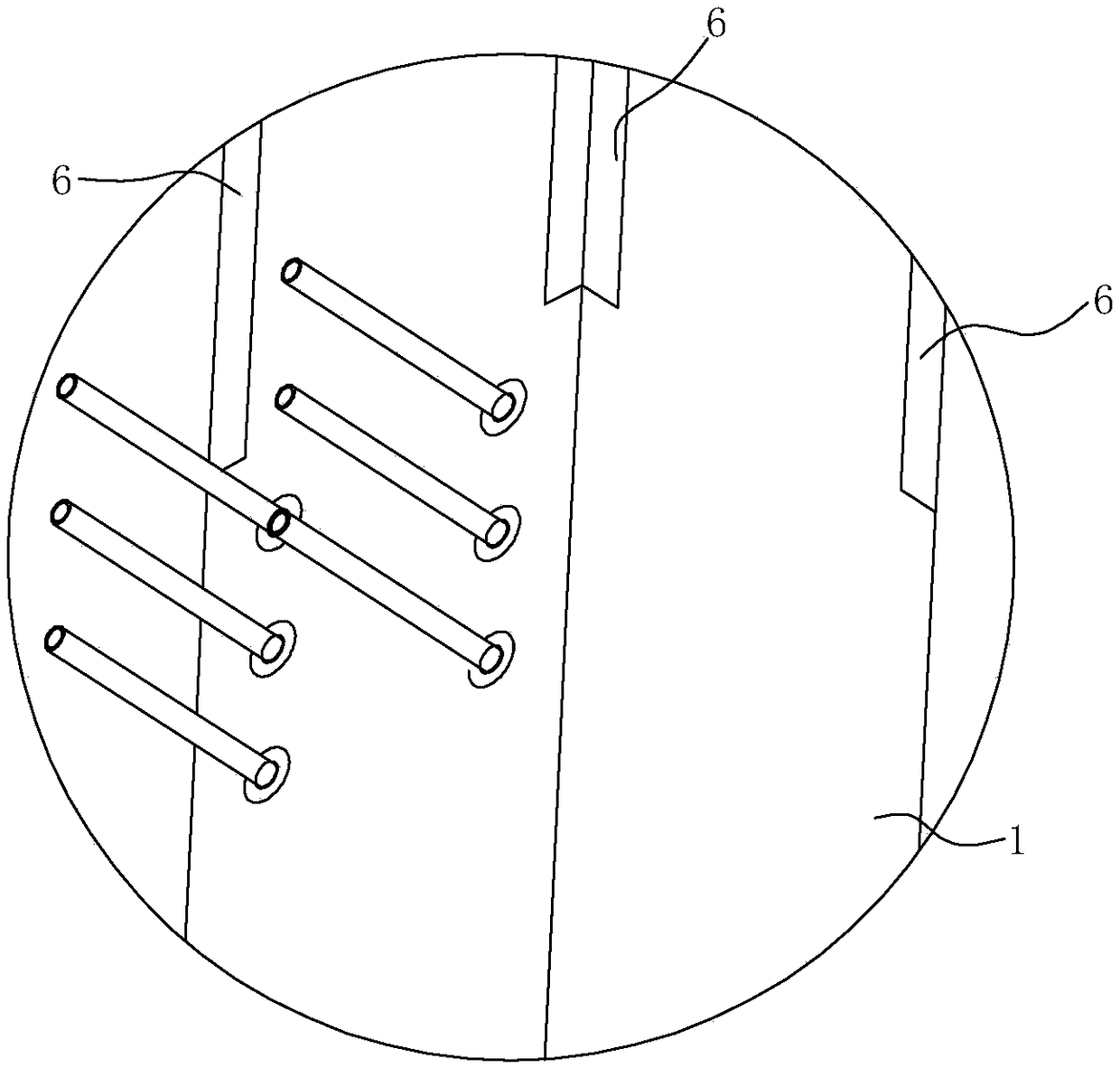

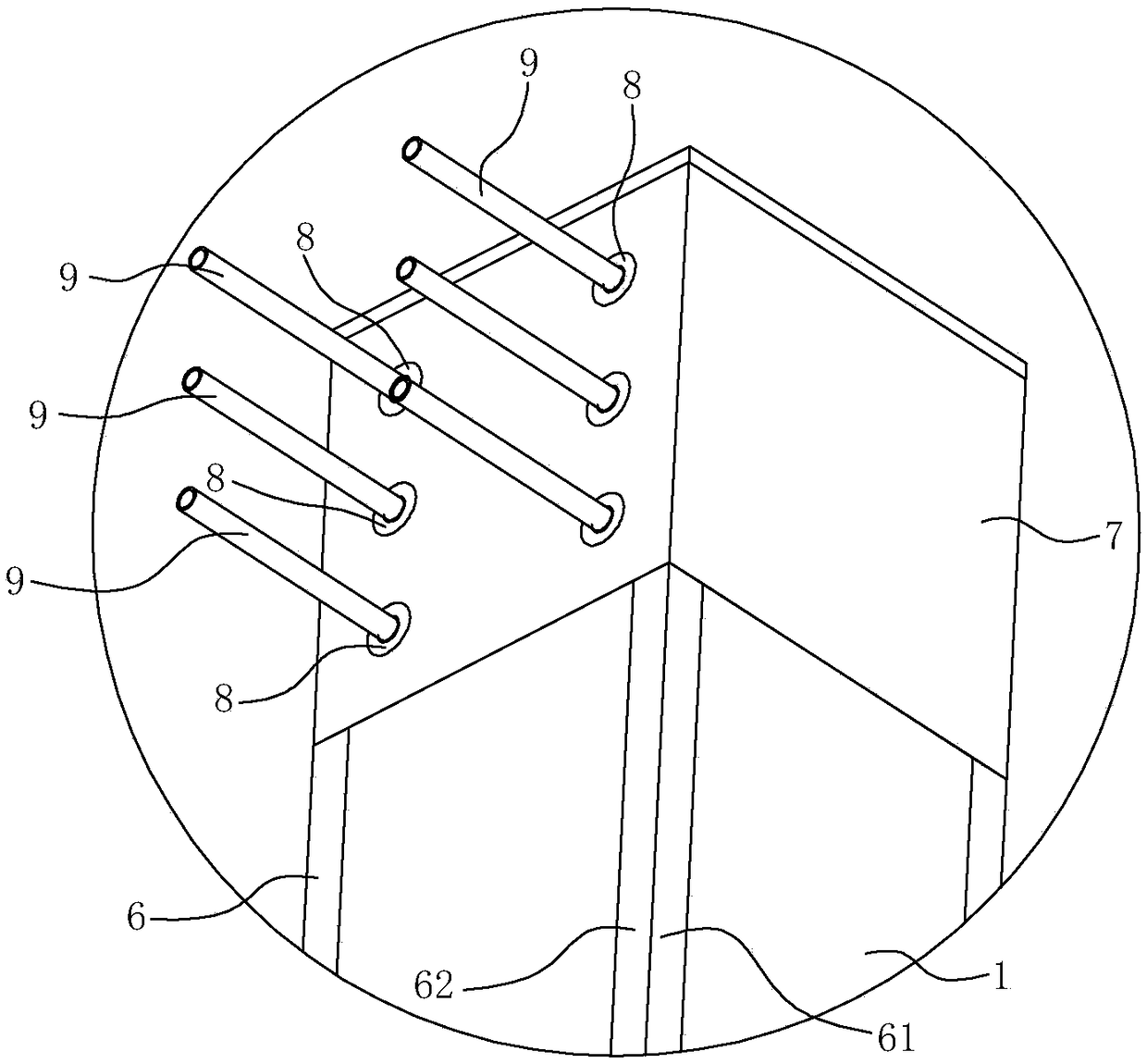

[0021] Such as Figure 1~5 Shown is a preferred embodiment of the present invention.

[0022] A rectangular concrete pile for constructing the side wall of a pipe gallery, comprising a pile body 1 with a rectangular cross section, and a plurality of middle anchor bars 2 protruding from the front end of the pile body 1 are provided in the middle of the pile body 1 .

[0023] The middle anchoring tendon 2 can be fixed to the pile body 1 in the following manner. The simplest way is that the middle anchoring tendon 2 is directly integrally formed with the pile body 1 as an insert.

[0024] The preferred method is: a plurality of central pre-embedded pipes 5 are pre-embedded in the middle of the pile body 1, and the front end openings of the central pre-embedded pipes 5 reveal the front end face of the pile body 1, and the middle anchor bars are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com