Construction method for expansion head anti-pressing and anti-pulling pile

A method of construction, the technique of enlarging the head, applied in the direction of sheet pile walls, foundation structure engineering, construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

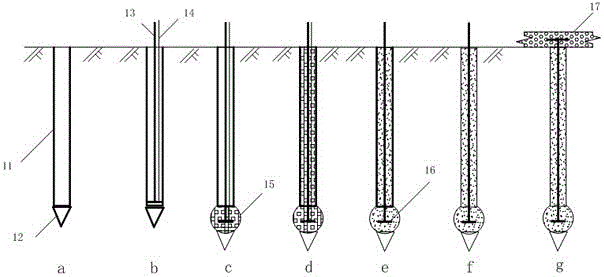

[0044] Such as figure 1 Shown, a kind of construction method of expanding head compression and uplift pile, comprises the following steps:

[0045] Step 1, prefabricating the anchor pulling device and the tamping device;

[0046] Described anchor pulling device comprises anchor cable 13 and the anchor plate 16 that is fixed on one end of anchor cable 13;

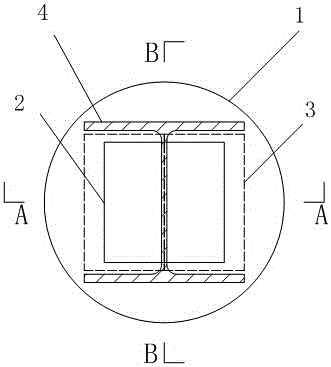

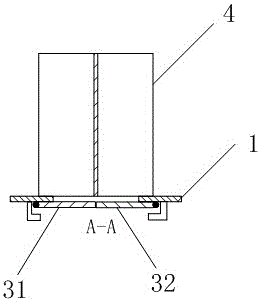

[0047] Such as Figure 2-5 As shown, the tamping device includes a circular bottom plate 1, a baffle plate 3, a dowel bar 4, a limit block 7 and a vibration generator. The circular bottom plate 1 is provided with a hole 2, and the center of the circular bottom plate 1 coincides with the center of the hole 2; the baffle plate 3 is hinged on the bottom surface of the circular bottom plate 1 by a horizontal rotating shaft 6, and the baffle plate 3 is a sheet shape, and its The size can block the hole 2 , the baffle plate 3 includes a first baffle plate 31 and a second baffle plate 32 with the same shape, and the first baffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com