Structure improvement of connector plug end for vehicles

A vehicle connector and connector plug technology, which is applied to the parts, connections, electrical components and other directions of the connecting device, can solve the problems of long assembly time, difficulty in automation, and difficulty in assembly, and achieves convenient automation and enhanced pull-out resistance. , the effect of increasing the assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

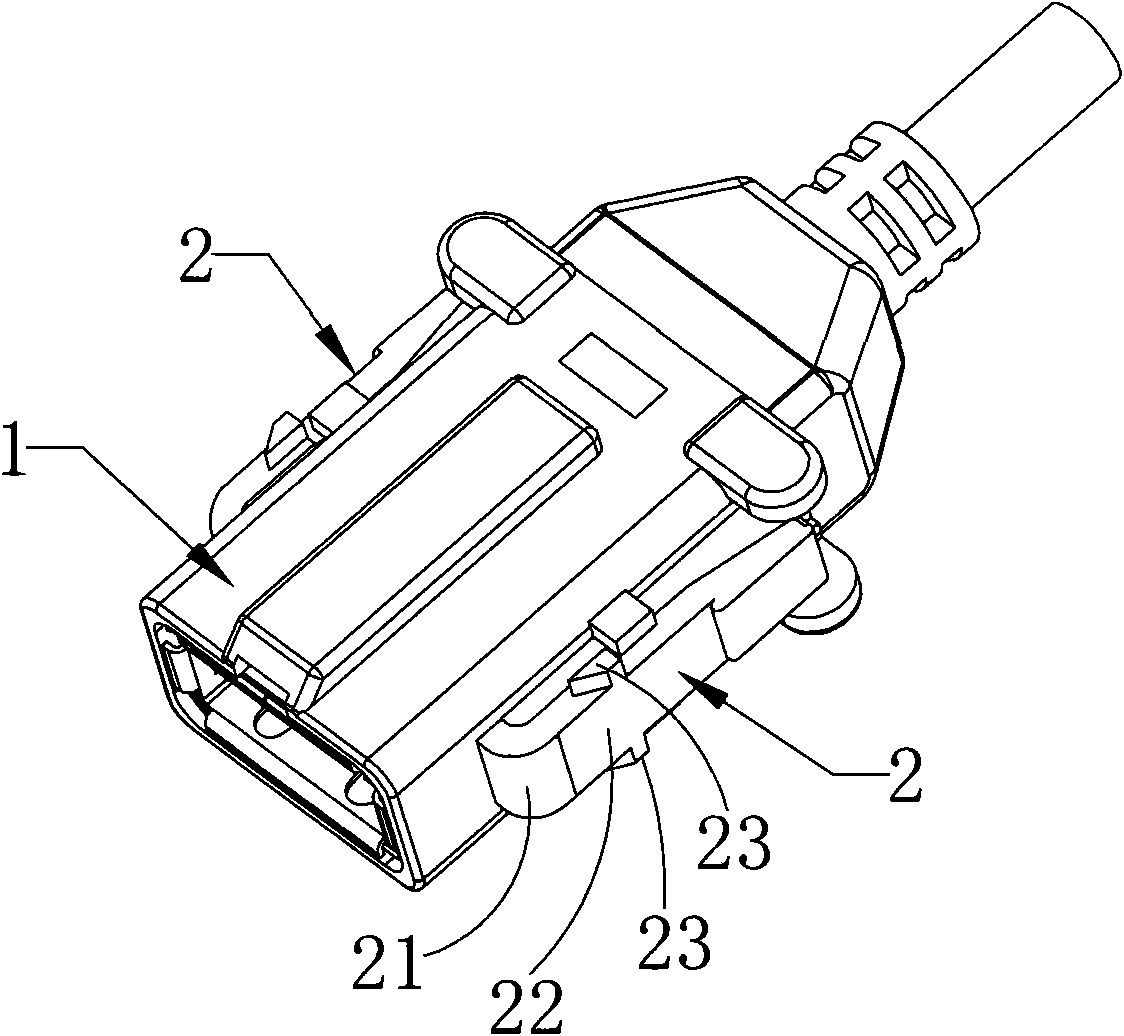

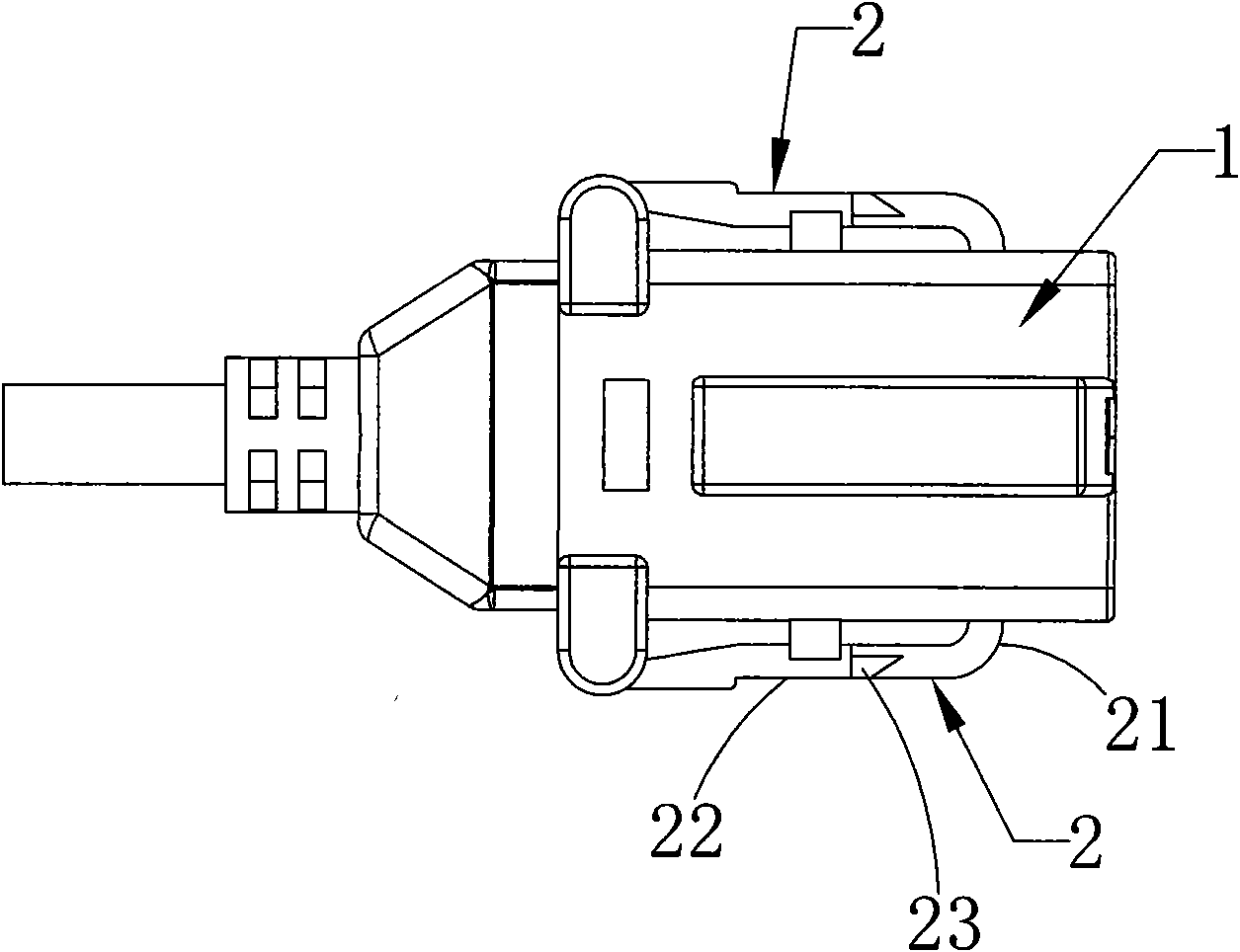

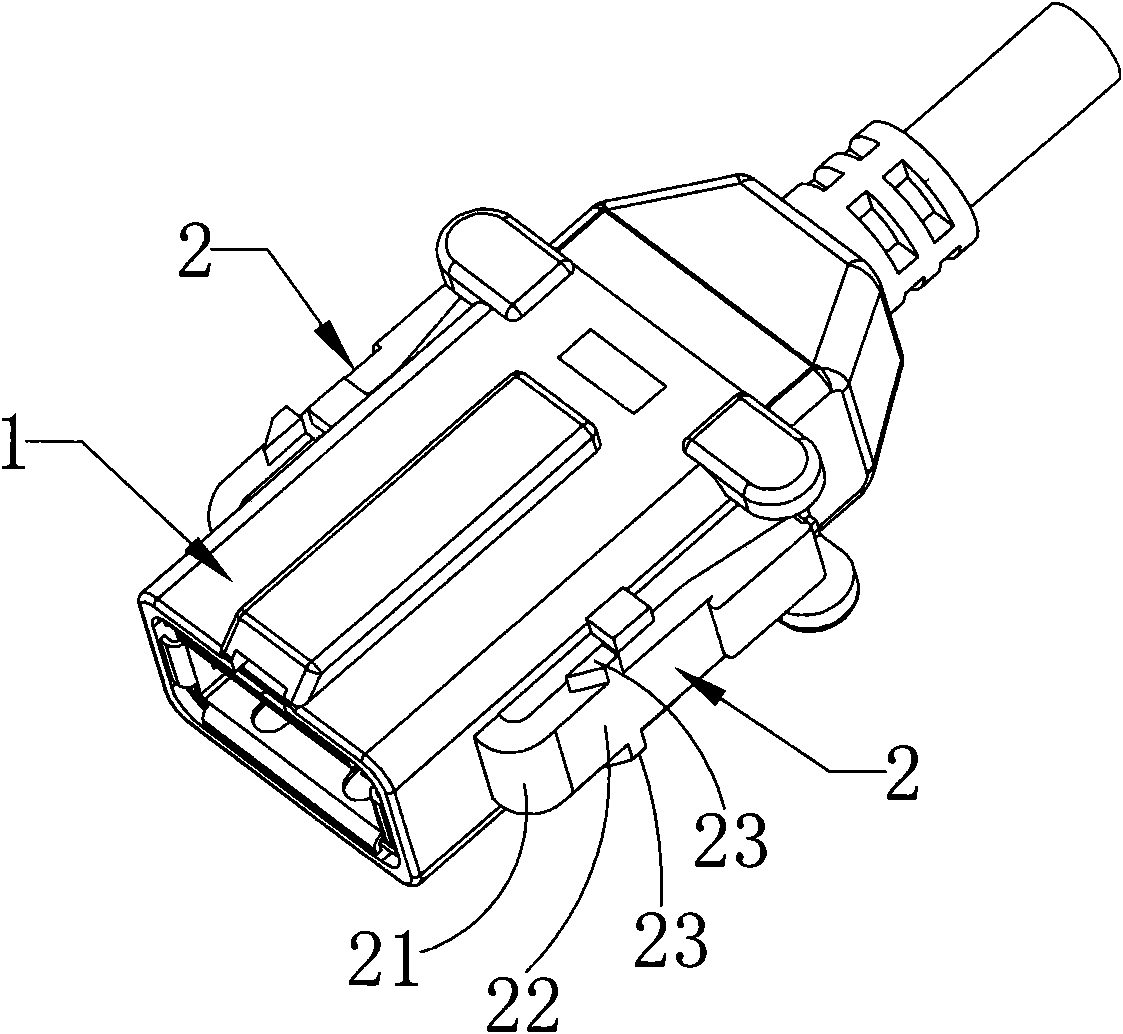

[0011] Embodiment: A structural improvement of the plug end of a car connector, the connector plug end has a plastic body 1, the two wider symmetrical planes among the four sides of the plastic body are the upper and lower sides, and the other two symmetrical planes are the left and right sides. , the right side, the outer surfaces of the left and right sides are respectively integrally connected with a plastic elastic buckle 2, the plastic elastic buckle has elasticity in the left and right direction, and the plastic elastic buckle is connected with the pair of accessories when it is not subjected to external force The corresponding parts are snapped together.

[0012] Taking the insertion direction of the plug end of the connector as the front and the pull-out direction as the rear, each plastic elastic buckle 2 is composed of a branch 21, an elastic arm 22 and two clamping points 23, and one end of the branch is connected to the plastic body Integral connection, the first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com