Composite connection type concrete filled steel tube bridge pier and construction method thereof

A technology of steel tube concrete and composite connection, which is applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of poor pullout resistance, shear resistance and earthquake resistance of bridge piers, low stability and safety of bridges, etc., and improve the deformation resistance , improve stability and safety, and improve the effect of forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

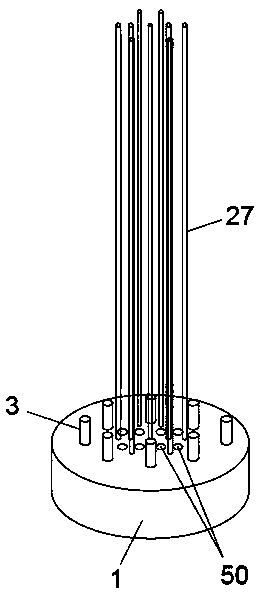

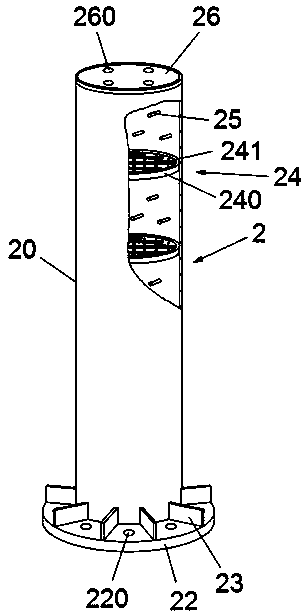

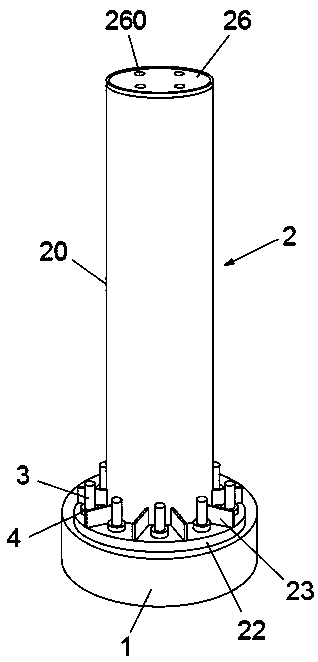

[0038] see Figure 1 to Figure 7 , a composite connected concrete-filled steel pipe pier, comprising a load-bearing foundation 1 poured on the ground and a steel-filled steel pipe 2 located at the upper end of the load-bearing foundation 1; The surrounding bottom plate 22 and the pier column concrete 21 cast in the steel pipe 20; the bottom plate 22 is provided with a plurality of fixing holes 220 for fixing the anchor bolts 3; the anchor bolts 3 pass through from bottom to top The fixing hole 220 is tightly matched with the nut 4 to lock the bottom plate 22 on the load-bearing foundation 1; the upper end of the load-bearing foundation 1 is embedded with a plurality of "U"-shaped stabilizing tubes 5; the "U"-shaped stabilizing tubes 5 The two openings 50 are connected with the inner cavity of the steel pipe 20, and the pier column concrete 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com