Construction method of concrete pile by soil extraction and pressure filling

A construction method and technology for pouring concrete, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of inability to operate continuously, lack of bearing capacity, poor effect, etc., to improve construction efficiency, use effect, and speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

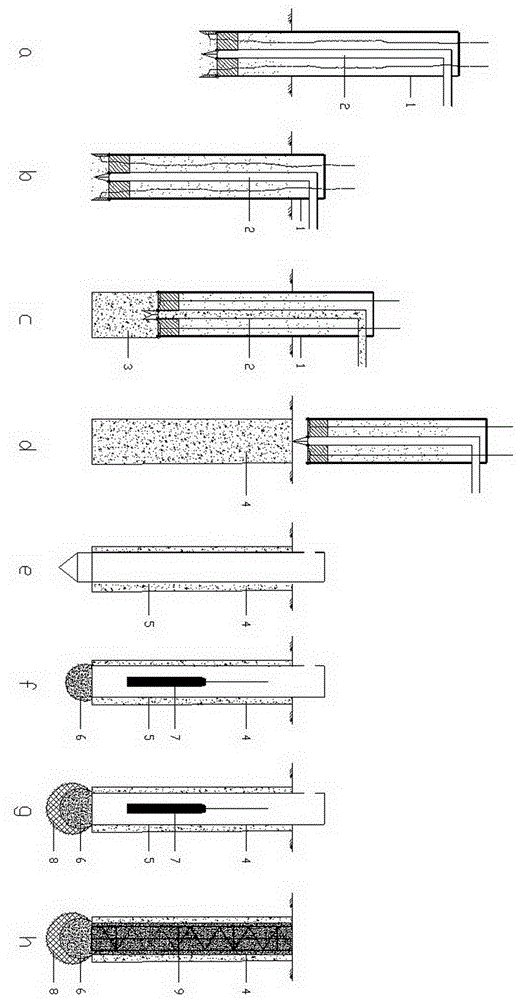

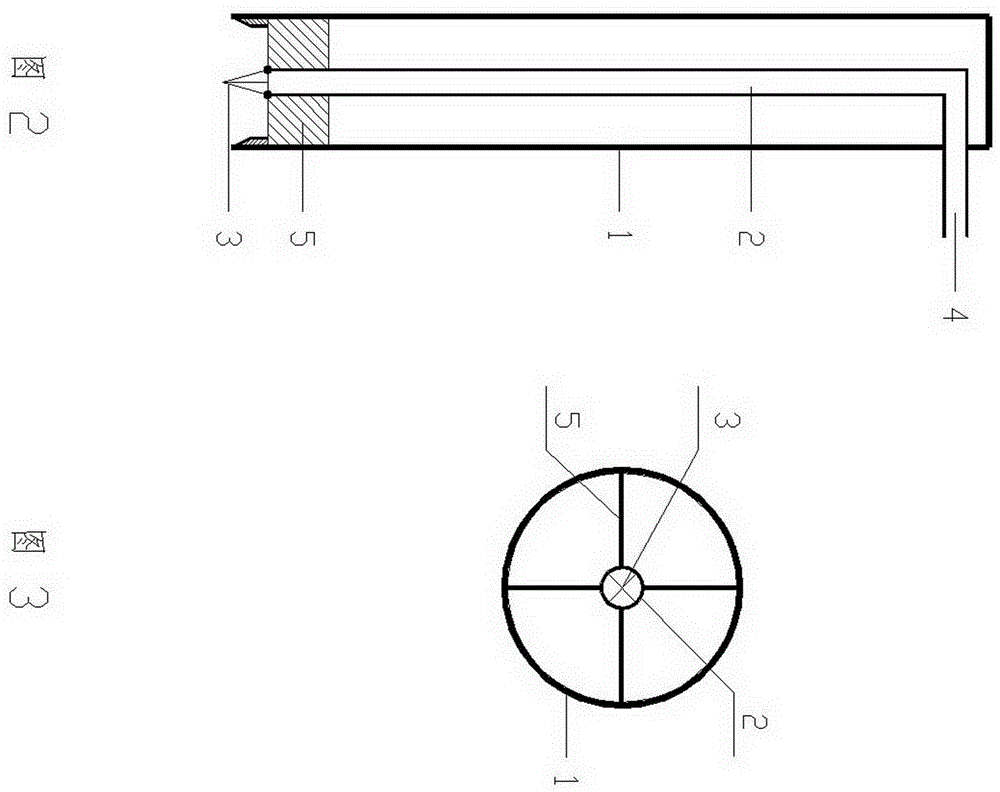

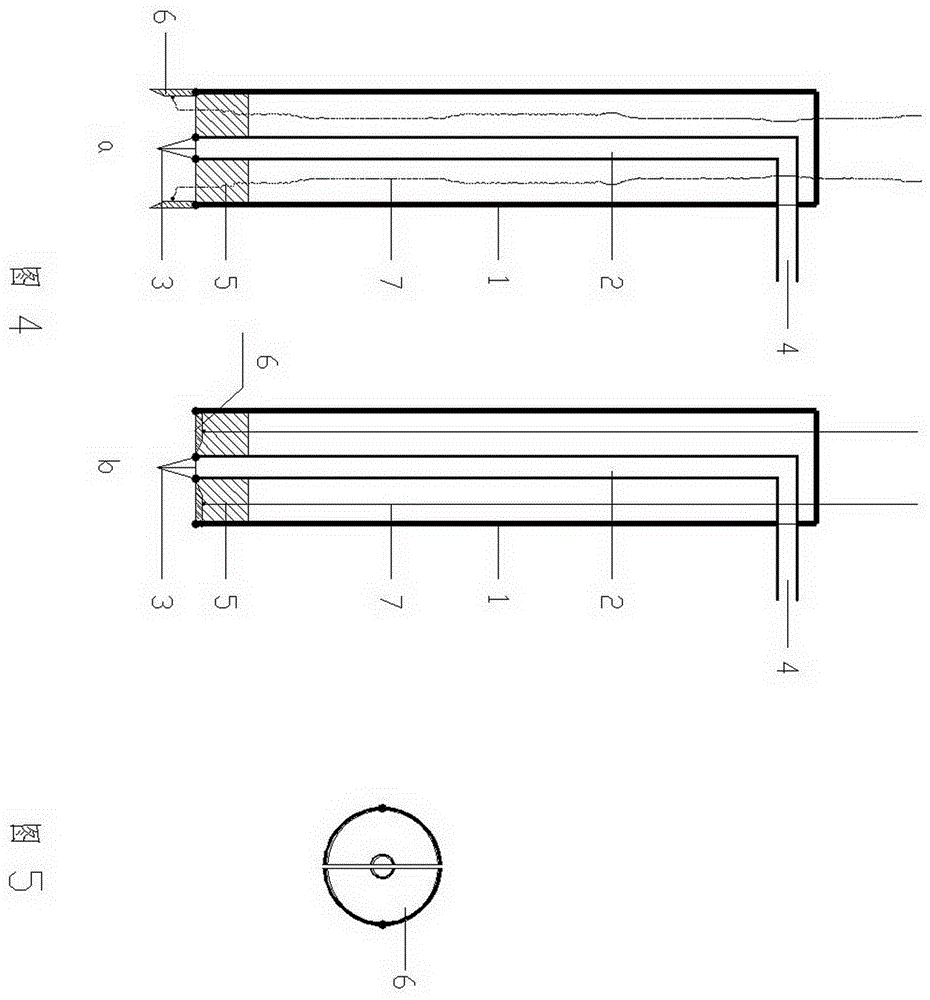

[0009] figure 1 is a schematic diagram of an embodiment of the construction method of the present invention, at first, as figure 1 As shown in a, the earth taking device 1 with the feeding pipe 2 is sunk into the soil body by hammering with a heavy hammer, and the in-situ soil pours in at the opening at the bottom of the soil taking device 1 during the sinking process. The inner chamber of earth taking device 1; Then, as figure 1 As shown in middle b, continuous hammering will sink the earth-taking device 1 to the set depth; then, as figure 1 As shown in middle c, while pumping the cement mixture 3 in the feed pipe 2 in the soil-taking device 1, the soil-taking device 1 is lifted upwards. The cement mixture 3 is formed by mixing cement, soil and sand with water. into, the cement mixture 3 is discharged at the bottom of the soil borrowing device 1 through the feeding pipe 2; then, as figure 1 As shown in middle d, the operation of pumping the cement mixture 3 and the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com