Tower crane foundation structure and its construction method

A construction method and technology of tower crane foundation, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of non-reusable use, generation of construction waste, waste of environment, etc., and achieve the effects of improving pullout resistance, strengthening connection force, and reducing engineering waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

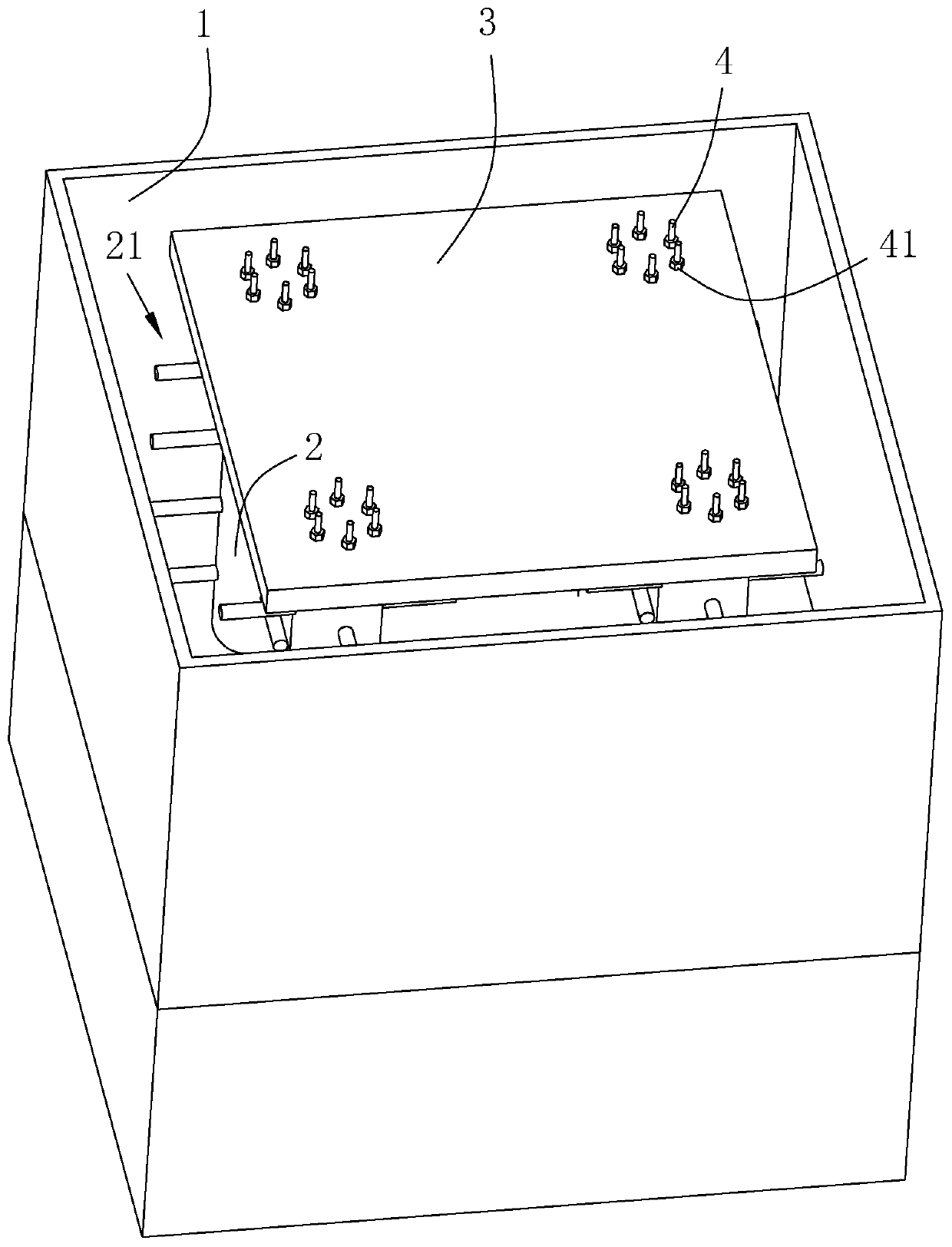

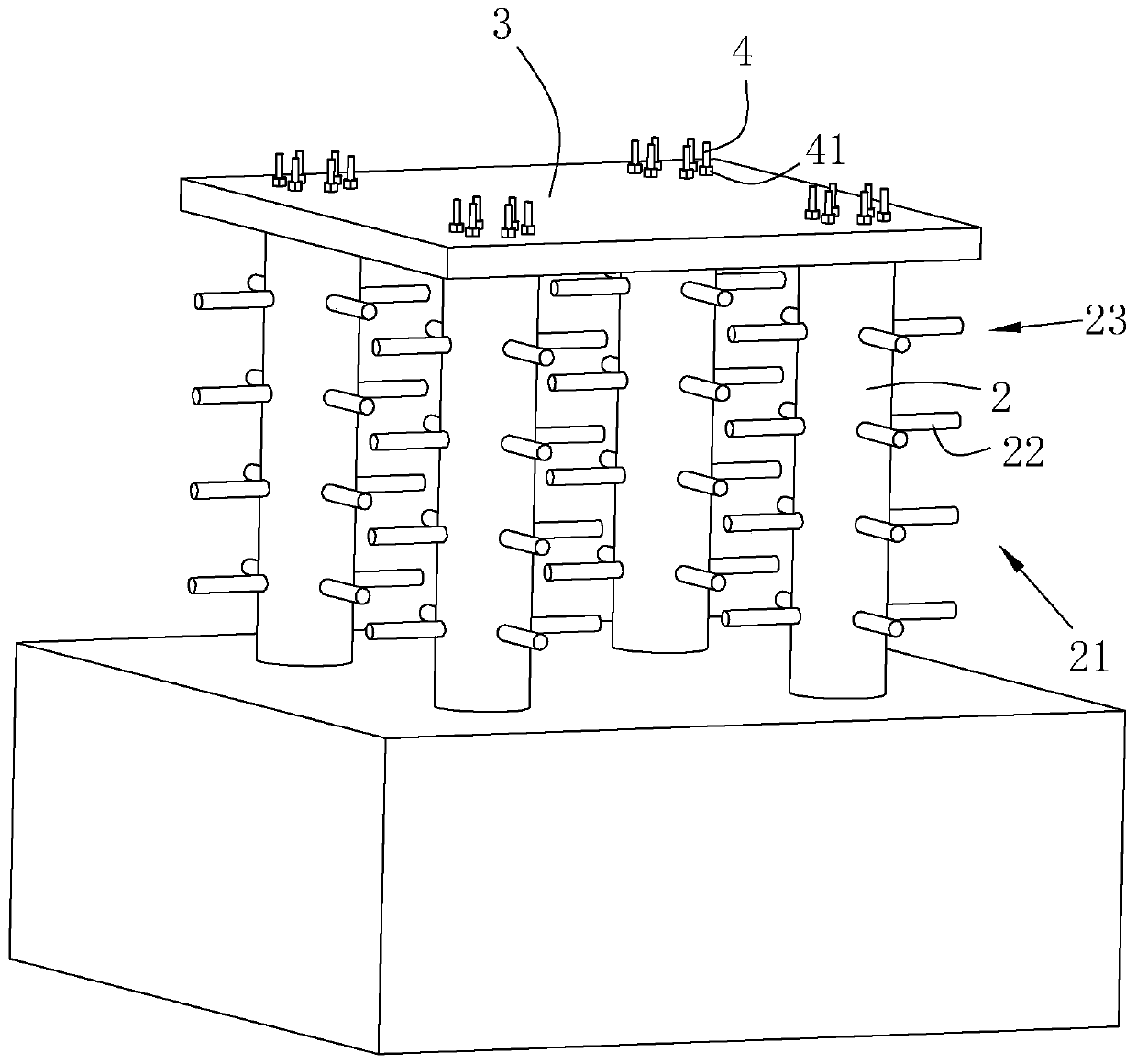

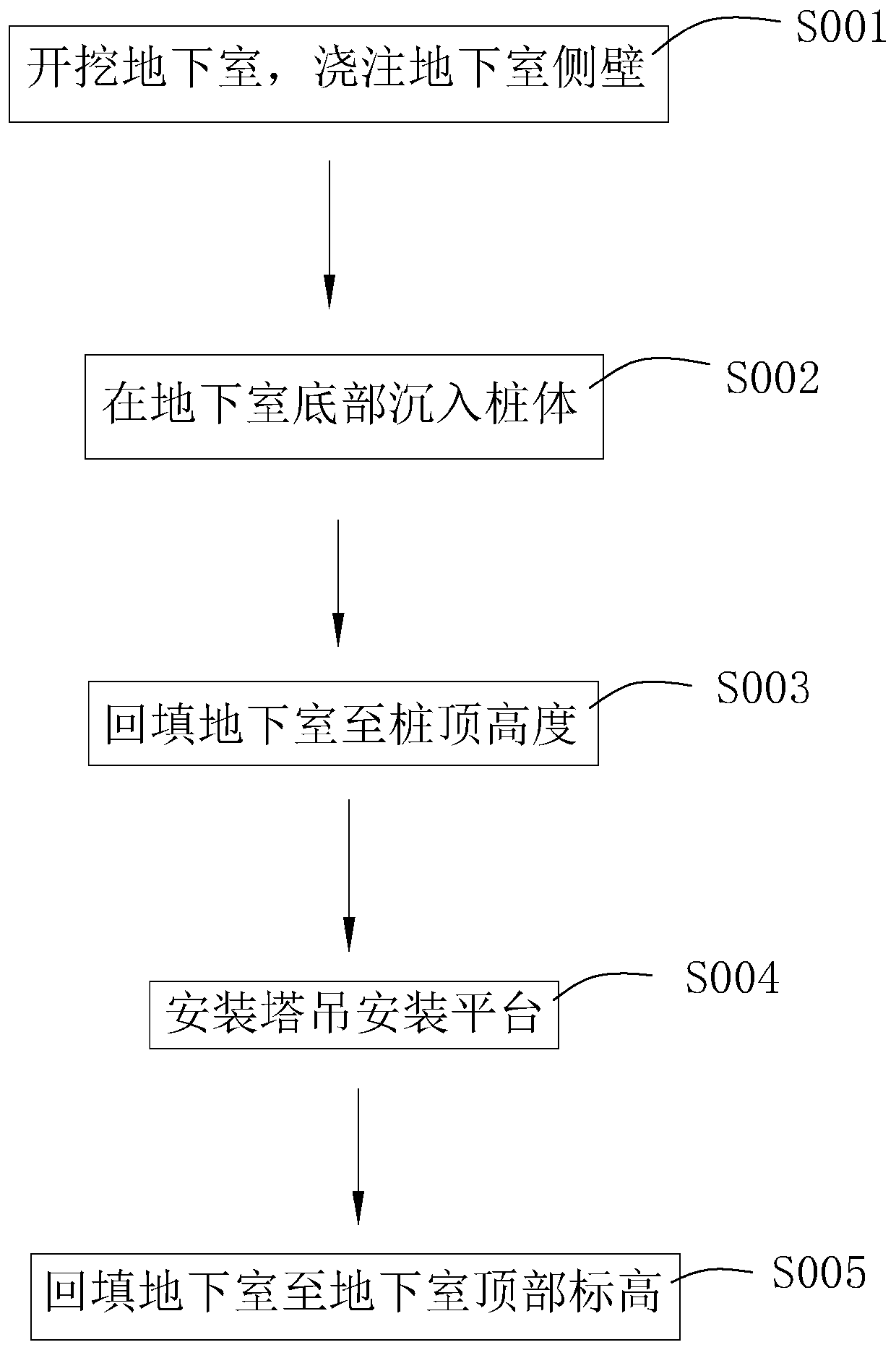

[0039] A tower crane foundation structure, refer to figure 1 as well as figure 2 , including several pile bodies 2 sunk into the bottom of the basement 1 along the vertical direction, the top of the pile bodies 2 is connected with a tower crane installation platform 3, and the basement 1 is filled with a dense soil layer.

[0040] Part of the pile body 2 sinks into the soil at the bottom of the basement 1, and part of it is located in the cavity of the basement 1. The height of the top of the pile body 2 is lower than that of the top of the basement 1. The side walls of the pile body 2 located in the basement 1 are provided with a number of bearings. The load-bearing member 21 is a load-bearing rod 22 extending radially outward along the pile body 2, and a plurality of load-bearing rods 22 are evenly distributed around the circumference of the pile body 2 in the horizontal direction to form a load-bearing portion 23. There are multiple force parts 23 and they are evenly dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com