Novel tree root structure pile and construction process thereof

A construction technique and tree root technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of low pile bearing capacity, weak pull-out and sliding resistance, etc., to increase bearing capacity, pull-out resistance And anti-skid performance improvement, the effect of reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

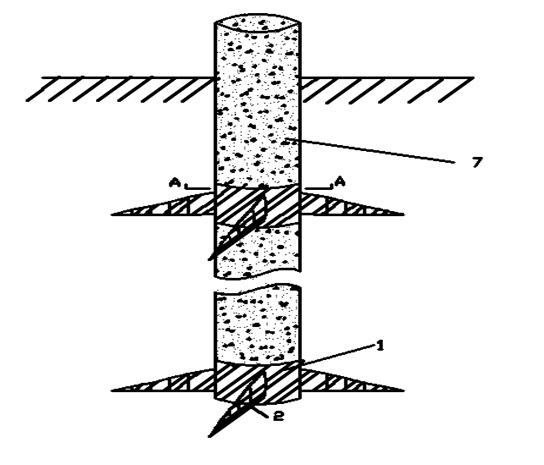

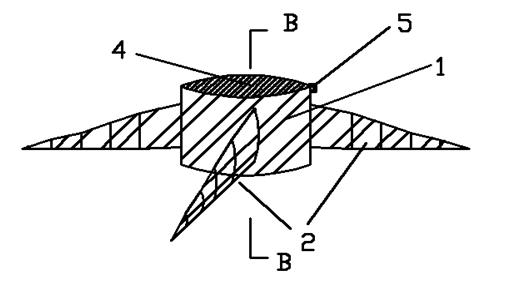

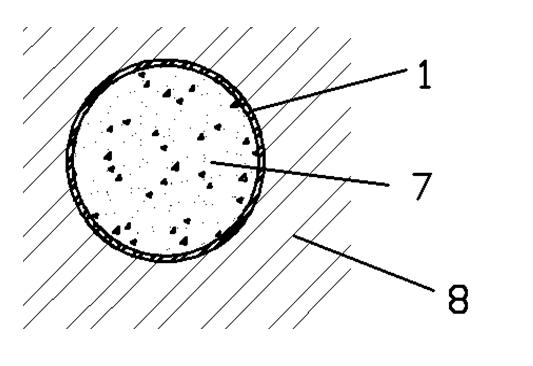

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described

[0027] Such as Figure 1-4 Shown, the main body structure of tree root shape of the present invention is hollow column 1, and hollow column 1 is the rigid column that has hole middle and lower part to separate with steel plate all around, is made up of steel plate or reinforced concrete plate. The lower end of the hollow column 1 is provided with a top cover 4, the lower end of the hollow column 1 is provided with a base 6, and the side wall of the hollow column 1 is provided with an expansion joint 2 communicating with the interior of the hollow column 1. The expansion joint 2 consists of a series of different thicknesses. Composed of pipes, the clamp is set so that the expansion joint 2 can only be stretched forward and cannot be retracted after stretching. At the beginning, the expansion joint 3 is not stretched, and is basically located inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com