Offshore wind power single pile-friction wing composite foundation and its construction method

A technology for offshore wind power and composite foundations, which is applied in foundation structure engineering, wind power generation, sheet pile walls, etc., and can solve problems such as the inability to realize the horizontal bearing capacity of single pile foundations, the easy bending and twisting of the wing plate structure, and the difficulty of construction , to achieve the effect of reducing the difficulty of production and transportation, simple construction, and improving the horizontal resistance of the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

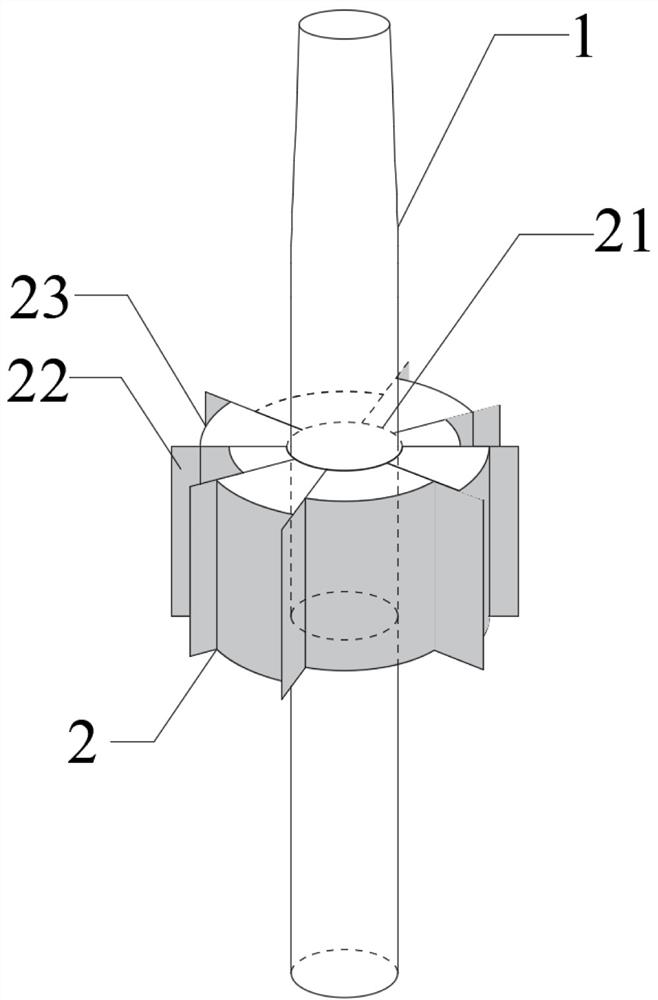

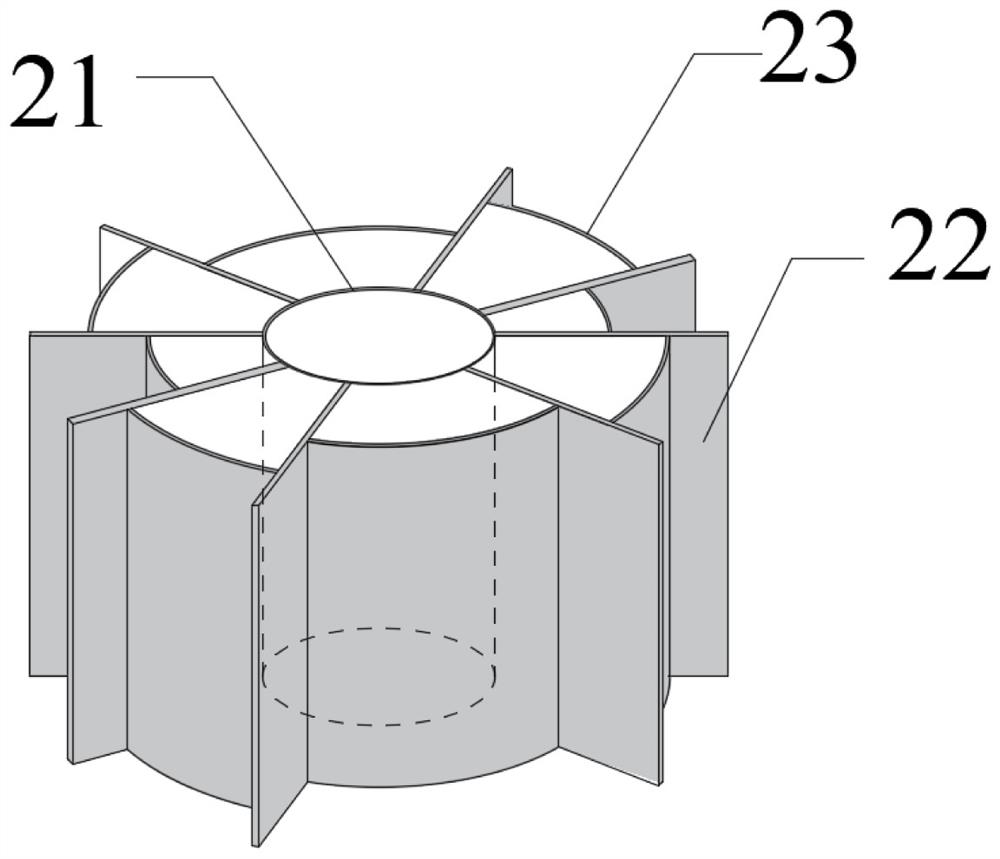

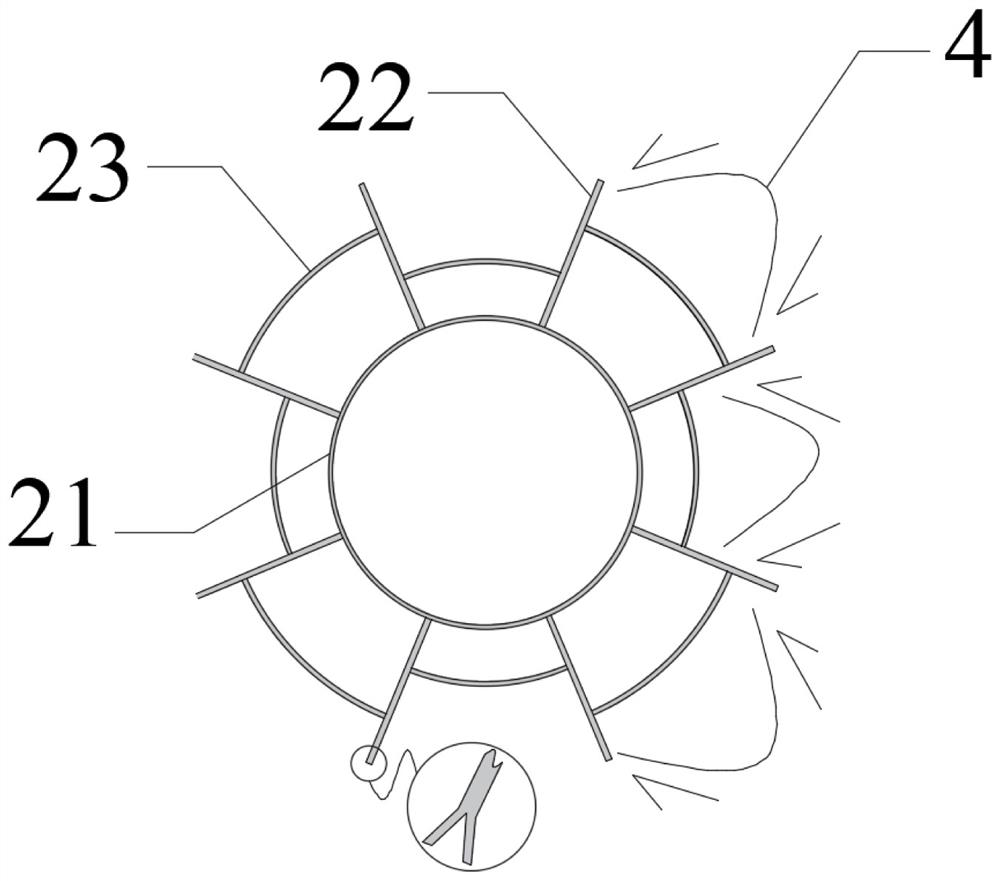

[0037] Such as Figure 1-Figure 8 Among them, an offshore wind power monopile-friction wing composite foundation, which includes a single pile 1 and a friction wing 2; The outer wall of the force tube 21 is connected, and the ring wing 23 is located outside the force transmission tube 21 and connected with the side wing 22; the side wing 22, the inner side of the ring wing 23 and the outer wall of the force transmission tube 21 form an axial through structure. The conical transition section 11 of the single pile 1 goes deep into the bearing layer of the seabed, and the force transmission tube 21 of the friction wing 2 located in the bearing layer is in close contact with the conical transition section 11 of the single pile 1, and the friction wing 2 is axially Through the structure, it is convenient to embed the bearing layer of the seabed. The structure of the wing 22 and the ring wing 23 of the friction wing 2 increases the interaction area between the composite foundation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com