Gas-liquid mixing device and method

A liquid mixing device and gas technology, applied in the directions of mixing methods, combination devices, separation methods, etc., can solve the problems of reduced purification effect, weak water-soluble oxygen capacity, increased energy consumption, etc. The effect of increased surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with specific embodiments.

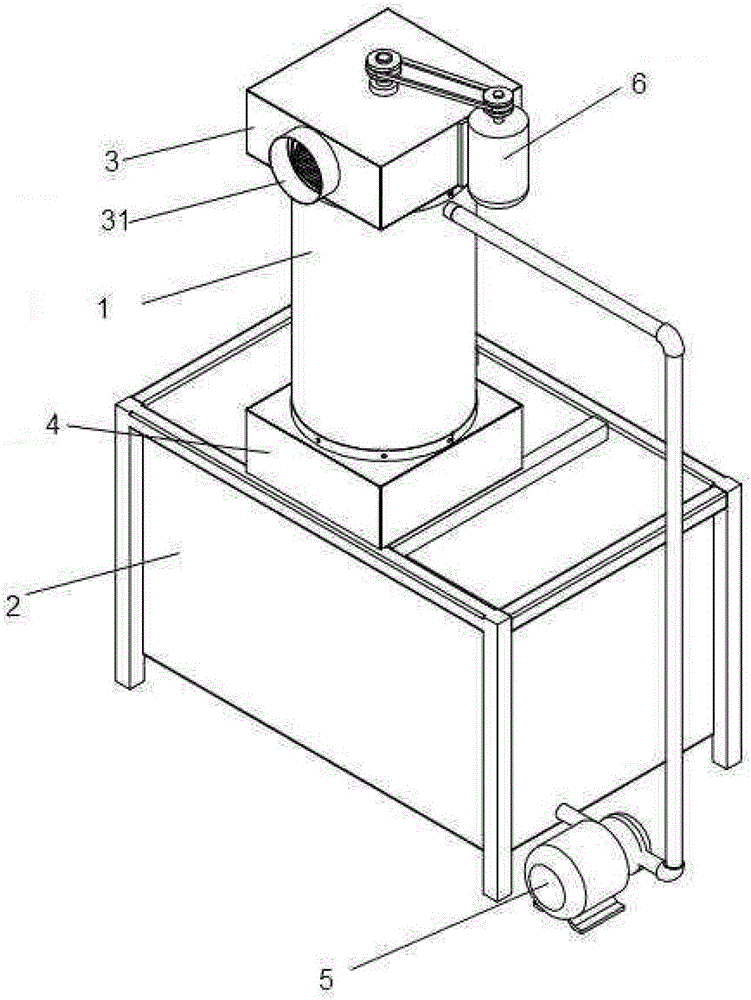

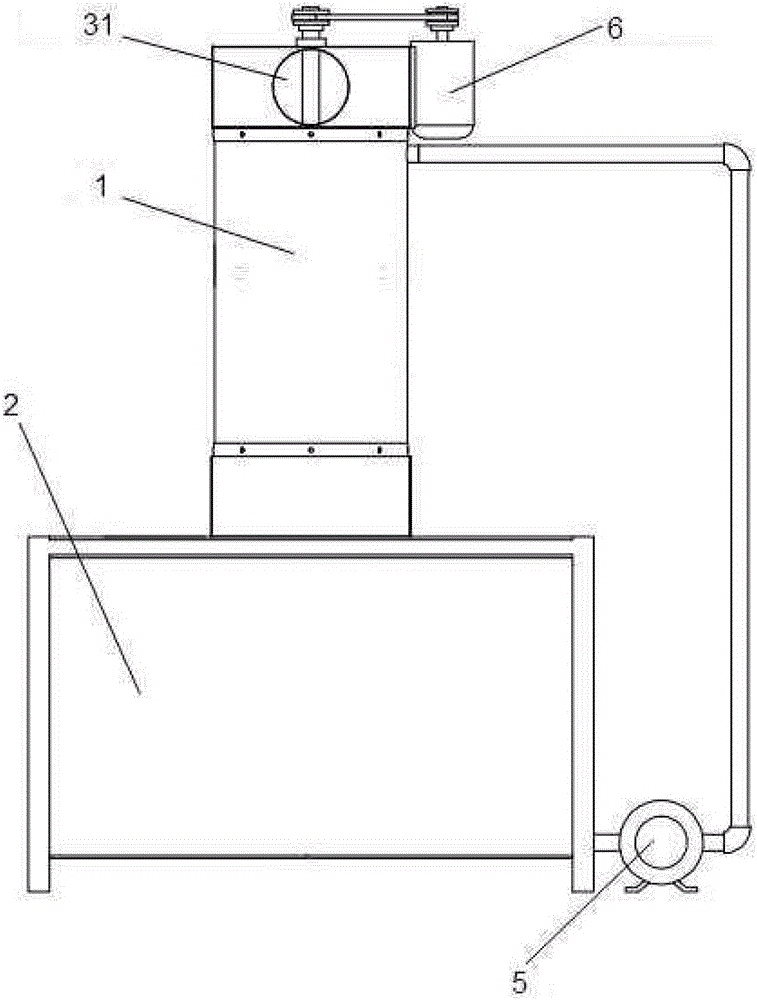

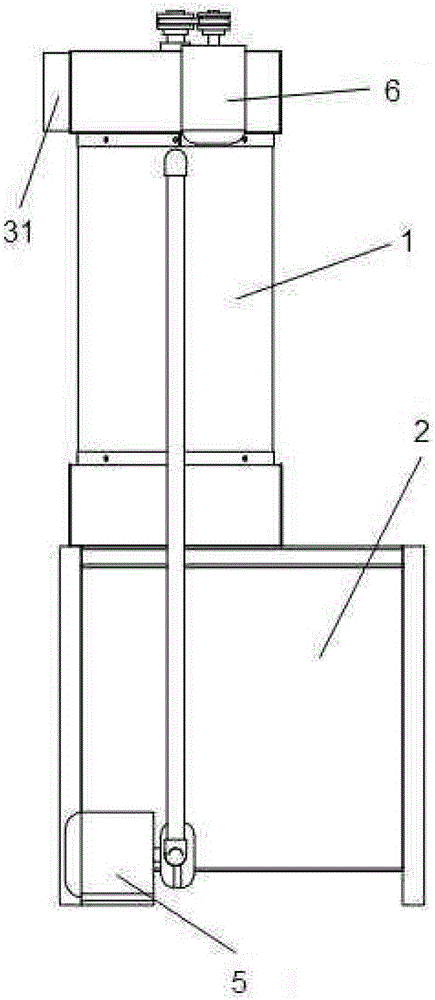

[0034] Figure 1-3 It is a schematic diagram of the overall structure of the present invention, wherein figure 1 It is a perspective view of the gas-liquid mixing device of the present invention; figure 2 It is the front view of the gas-liquid mixing device of the present invention; image 3 It is a side view of the gas-liquid mixing device of the present invention.

[0035] Such as Figure 1-3 As shown, the gas-liquid mixing device of the present invention includes a housing 1, an air inlet box 3 connected to the top of the housing, an air outlet box 4 connected to the bottom of the housing, a water tank 2 connected to the bottom of the air outlet box; , the pump 5 connected to the bottom of the water tank through a pipeline; the pump is also connected to the water inlet on the top of the casing through a pipeline; a motor 6 is arranged outside the air intake box, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com