Arch bar base and construction method

A construction method and arch slab technology, which is applied in the field of arch slab foundations, can solve problems such as poor structural rigidity, achieve the effects of reduced slip resistance, enhanced horizontal force resistance, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

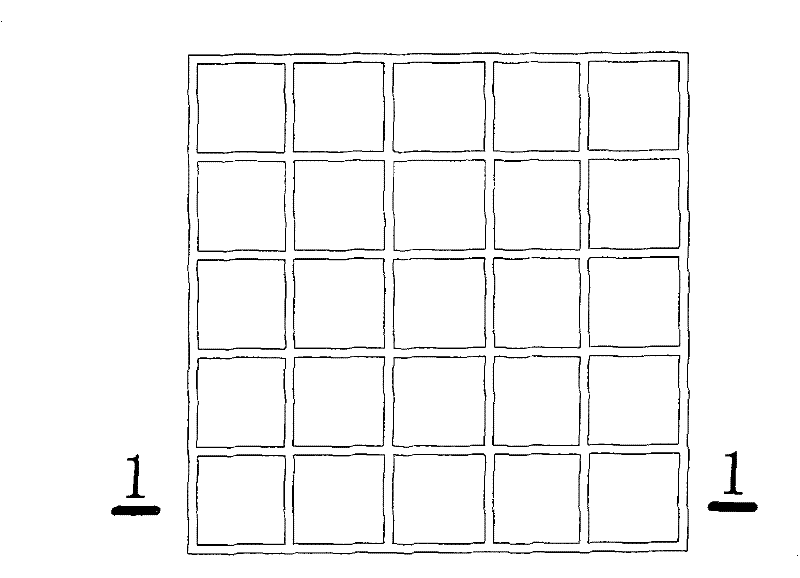

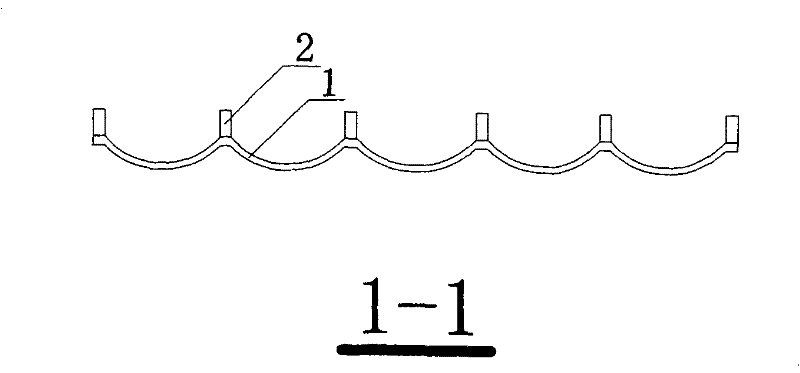

Image

Examples

Embodiment 1

[0034] 1) The site is flat.

[0035] The site is leveled to the design elevation, and when the site soil is leveled, use a road roller to roll back and forth until there is no trace. After the site is leveled, drainage should be done well.

[0036] 2) Make the arch groove.

[0037] Make an arch groove on the foundation soil 2, check the size after the arch groove is formed, and control the error within 10mm. After the arch groove is completed, the exposure time should be reduced as much as possible, and the sun, rain and water immersion should be strictly prevented to avoid deformation of the arch groove.

[0038] 3) Pour and pound the cushion.

[0039] C20 fine stone concrete is used as the cushion layer, and the thickness of the fine stone concrete cushion layer is 50cm, so as to eliminate the size error of the soil tire as much as possible in the cushion layer.

[0040] 4) Set up arch plate 1 formwork.

[0041] The radius of the arch plate 1 is the same as the column d...

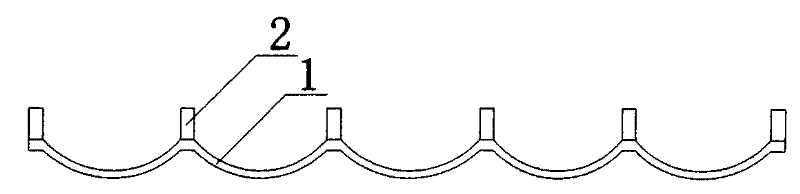

Embodiment 2

[0059] 1) The site is flat.

[0060] The site is leveled to the design elevation, and when the site soil is leveled, use a road roller to roll back and forth until there is no trace. After the site is leveled, drainage should be done well.

[0061] 2) Make the arch groove.

[0062] Make an arch groove on the foundation soil 2, check the size after the arch groove is formed, and control the error within 10mm. After the arch groove is completed, the exposure time should be reduced as much as possible, and the sun, rain and water immersion should be strictly prevented to avoid deformation of the arch groove.

[0063] 3) Pour and pound the cushion.

[0064] C20 fine stone concrete is used as the cushion layer, and the thickness of the fine stone concrete cushion layer is 50cm, so as to eliminate the size error of the soil tire as much as possible in the cushion layer.

[0065] 4) Place the prefabricated arch 1.

[0066] The radius of the prefabricated prefabricated arch plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com