Construction process of bridge insertion-plate-type noise barrier

A construction technology and sound barrier technology, which is applied in the direction of buildings, roads, road safety devices, etc., can solve the problems of insufficient strength of the base layer of the sound barrier board and low stability of the sound barrier board, so as to ensure long-term safe use and improve construction quality , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

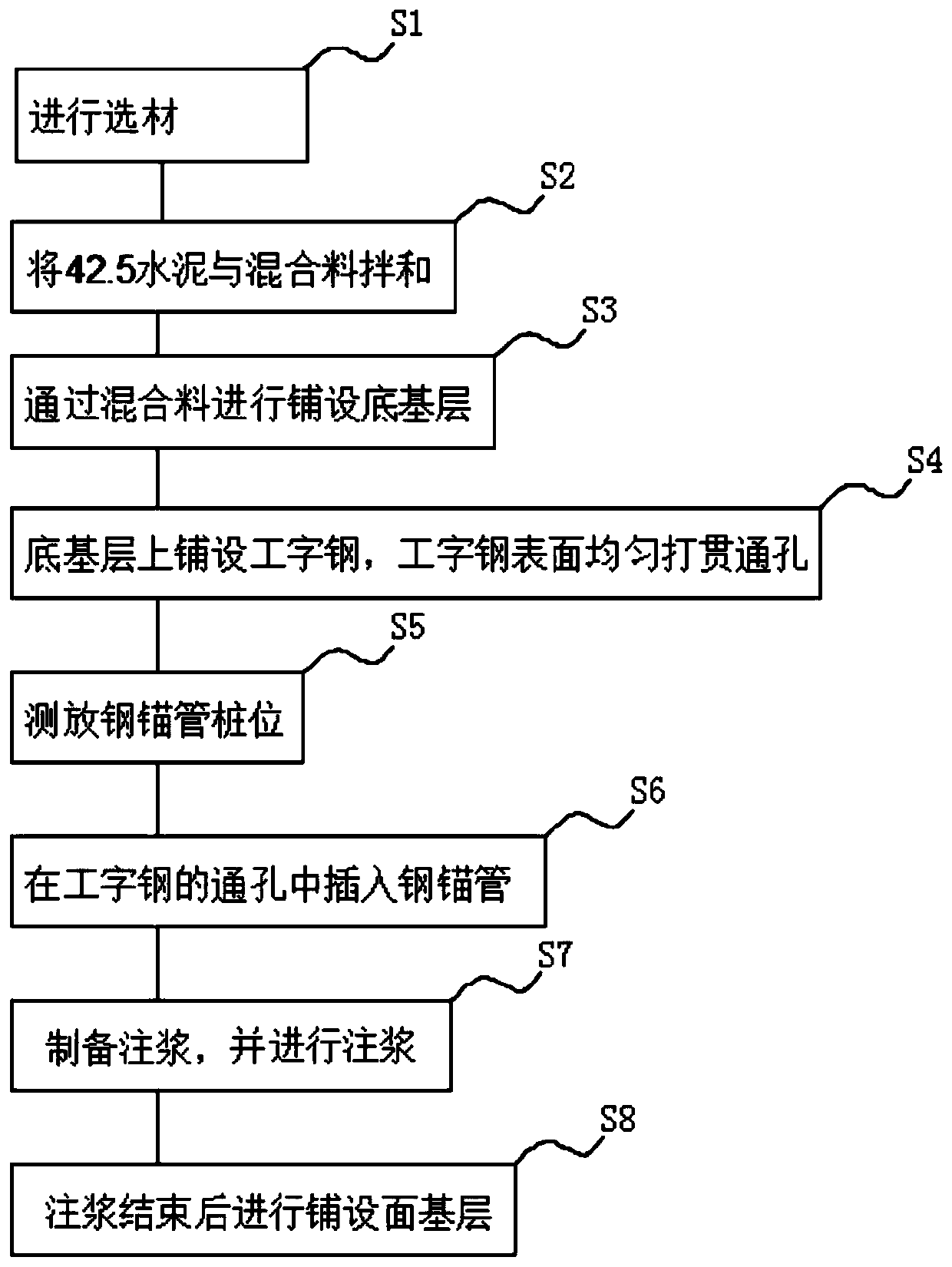

[0024] refer to figure 1 As shown, the present invention provides a construction technique for a bridge insert type sound barrier, comprising the following steps:

[0025] S1. Select materials, select 3%-5% of dry and dust-free crushed stones with a particle size of 3-5mm, 10%-20% of crushed stones with a particle size of 5-10mm, and 24%-36% of crushed stones with a particle size of 10-20mm. %, 12% to 25% of gravel with a particle size of 20 to 31.5mm and 10% of fine sand to form a mixture;

[0026] S2, mixing 42.5 cement with the mixture, the amount of cement is 2.5% to 4.5% of the mixture, and the amount of water is 4% to 6% of the mixture;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com