Method for increasing horizontal bearing capacity of pile foundation by using steel-gravel cylinder structure around pile

A horizontal bearing capacity, sand and gravel technology, applied in the direction of infrastructure engineering, soil protection, construction, etc., can solve specific construction difficulties, increase the amount of materials, affect the cost of construction, etc., to control the deformation of the pile body and improve the horizontal resistance , The effect of improving the overall horizontal bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

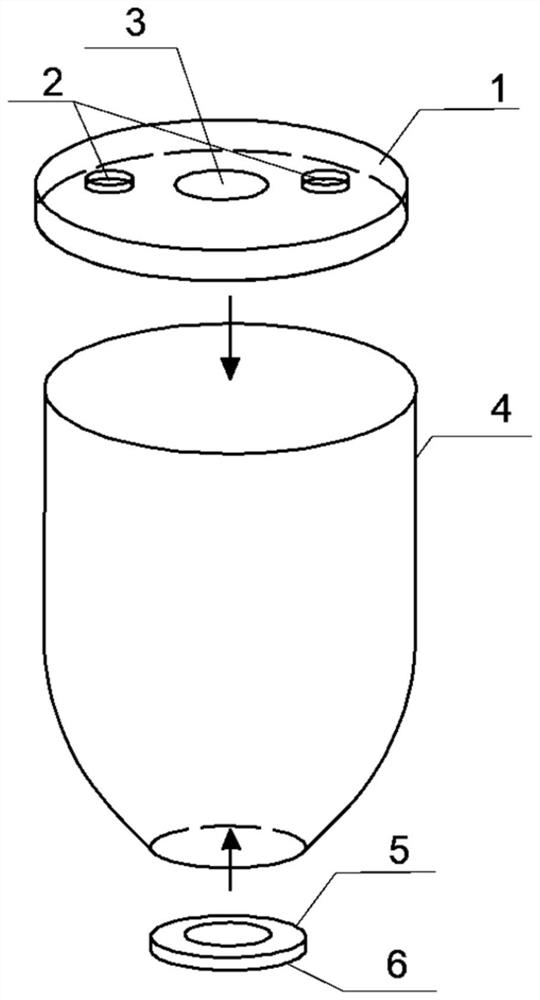

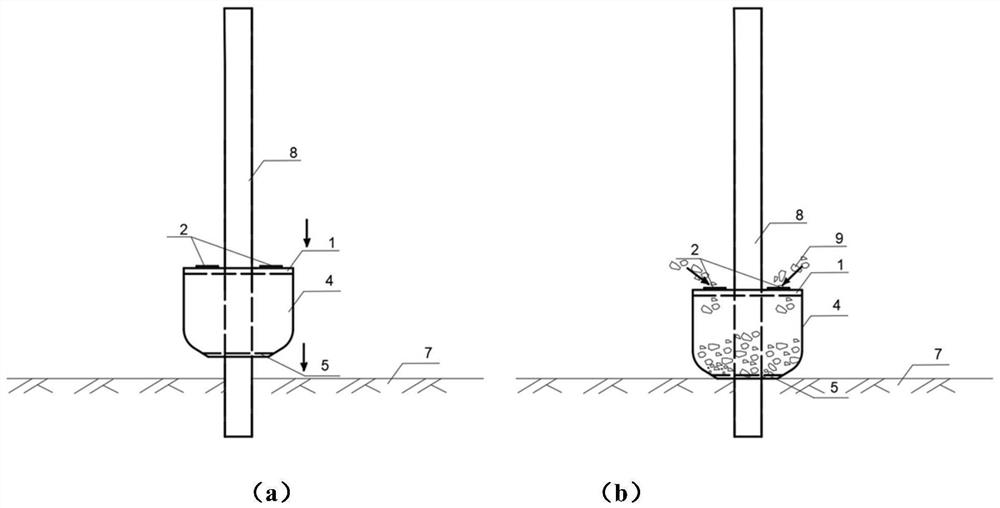

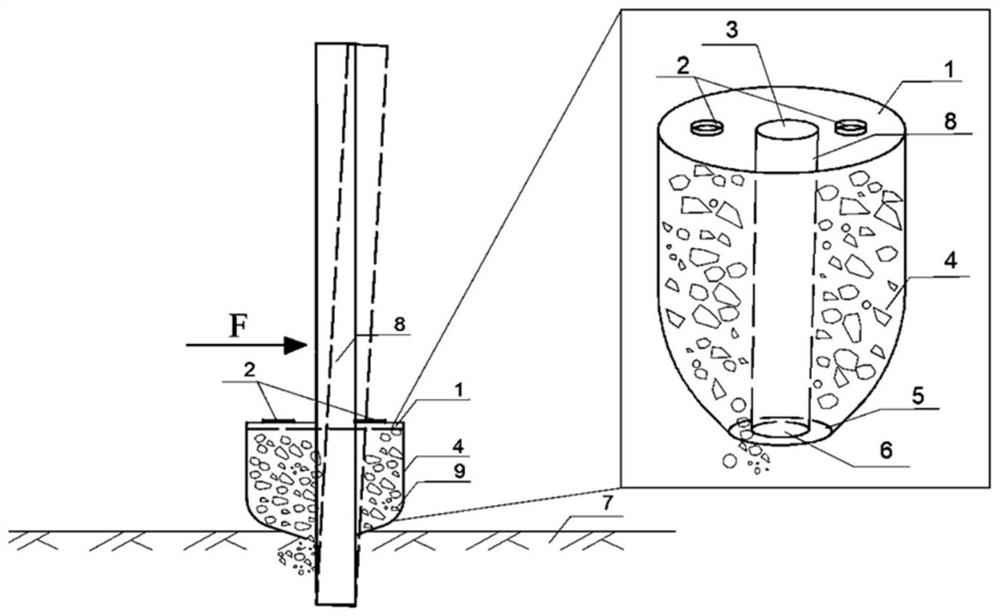

[0031] see figure 1 As shown, the present invention designs a steel cylinder member attached to the pile circumference, the steel cylinder member is a steel cylindrical shell 4 with a hollow inner cavity, and the bottom of the steel cylindrical shell 4 is funnel-shaped, It is conducive to the concentration of internal materials to the center. The top and bottom of the steel cylindrical shell 4 are sealed by welding the top cover 1 and the bottom plate 5, but the top cover 1 and the bottom plate 5 are respectively provided with a top reserved hole 3 and a bottom reserved hole 6, and the top reserved hole 3 The purpose of the reserved hole 6 and the bottom is to enable the steel cylinder member to be integrally placed on the body of the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com