Pile body toughening and monitoring device based on assembly ribs

The technology of monitoring device and pile body is applied in the direction of measuring device, field foundation soil survey, foundation structure test, etc., which can solve the problems of sensor layout difficulty, reduce the layout difficulty, increase the toughness of the pile body, and improve the rigidity of the pile body. and the effect of horizontal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

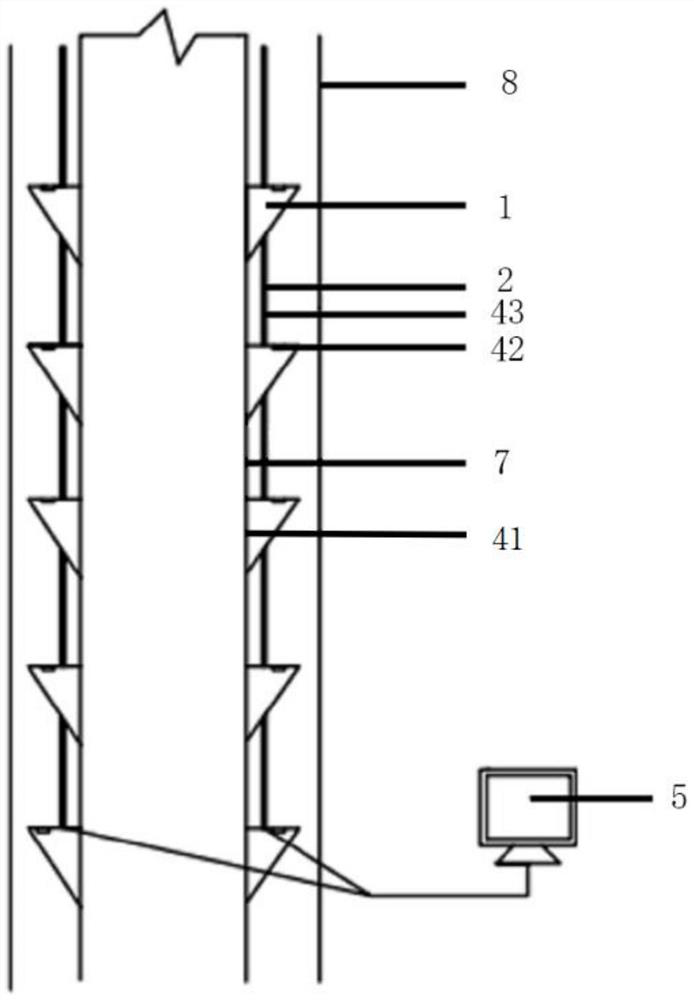

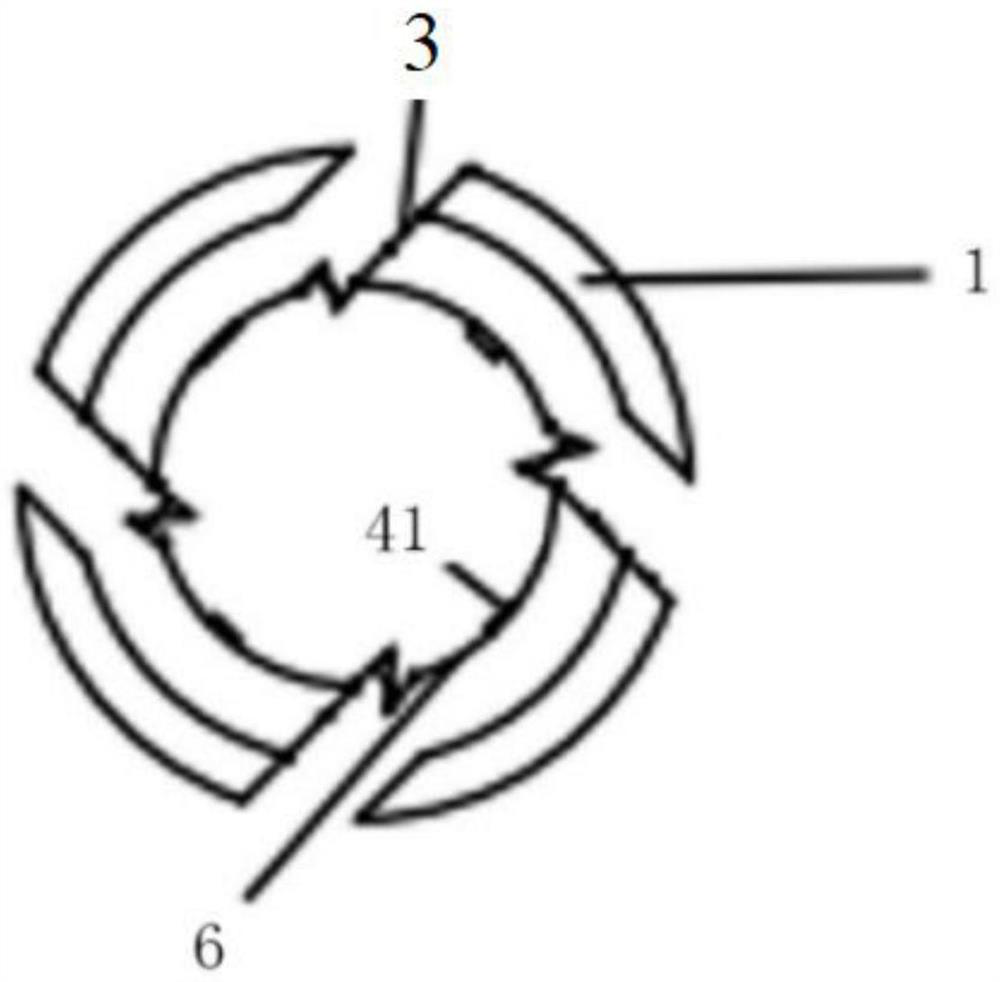

[0025] The two ends of the hinge 3 are respectively connected to the pile body and the assembly rib; the connecting rod 2 is connected to the joint between the assembly rib 1 and the hinge 3 in the same vertical direction; the pile body is equipped with a sensing device 4 to monitor the displacement of the pile body, soil pressure, The depth of the pile body into the soil; the sensing device 4 is electrically connected with the intelligent data acquisition device 5 .

[0026] The inner casing 7, the gasket 6, and the outer casing 8 are arranged sequentially from the inside to the outside, and the gasket 6 is arranged between the inner casing and the assembly rib.

[0027] The displacement sensor 41 is located on the contact surface between the washer 6 and the inner casing 7, and is used for monitoring the displacement of the pile body.

[0028] The pressure sensor 42 is located on the contact surface between the assembly rib 1 and the soil layer, and is used for monitoring th...

Embodiment 2

[0033] The outer casing 7 is to protect the internal structure, in order to ensure that the gasket 6 and the assembly rib 1 are fastened to the inner casing 7, the axes of the inner casing 7, the outer casing 8 and the gasket 6 must coincide;

[0034] Connecting rod 2 will assemble the connection of rib 1 in the same vertical direction;

[0035] The pressure sensor 42 is located on the contact surface between the assembly rib 1 and the soil layer, and is used to monitor the pressure of the soil layer, and is connected with the connecting rod 2, and transmits the data to the intelligent data acquisition device 5;

[0036] The stay wire displacement meter 43 is connected with the connecting rod 2, and is used for monitoring the depth of the pile body into the soil, and transmits the data to the intelligent data acquisition device 5;

[0037] The intelligent data collection device 5 transmits the data collected by the displacement sensor 41 , the pressure sensor 42 , and the wire...

Embodiment 3

[0041] At the beginning, first hollow out and sink into the outer casing 8, and the outer casing 8 plays a protective role for the internal structure;

[0042] Further, first connect the assembly rib 1, the connecting rod 2 and the inner casing 7 on the ground, and simultaneously arrange the displacement sensor 41, the pressure sensor 42 and the wire displacement gauge 43;

[0043] Further, sink the assembled parts and carry out pile construction;

[0044] Further, after the construction of the pile body is completed, the connecting rod 2 is rotated so that the washer 6 is tightly fastened with the pile body, and the installation is completed.

[0045] The pressure sensor 42 is installed on the contact surface between the assembly rib 1 and the soil layer. As the depth of penetration increases, the pressing force of the soil layer on the assembly rib 1 will also increase. The pressure sensor 42 transmits the signal to the intelligent data acquisition device 5 through wires.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com