Partially buoyant offshore platform for offshore wind power, bridges and marine structures and construction method

A technology for offshore platforms and construction methods, which is applied to bridges and marine buildings with local buoyancy and construction, offshore wind power, and can solve the problems of difficult construction and high foundation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

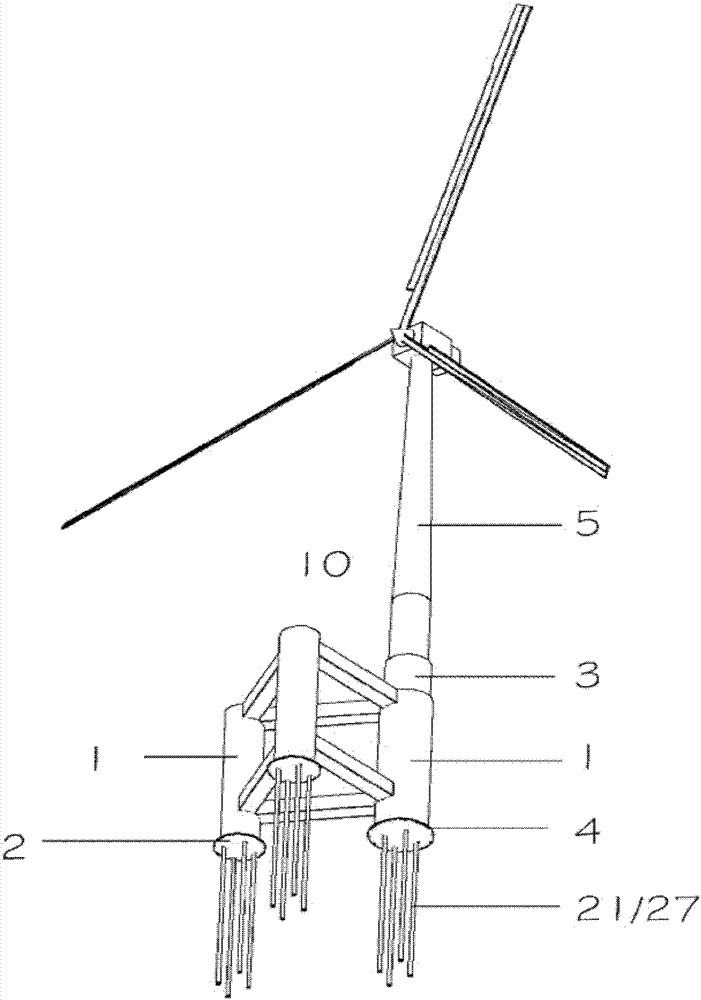

[0104] The purpose of construction in this embodiment is to install local buoyancy offshore platforms 10 (hereinafter referred to as partially buoyant offshore platforms 10) for offshore wind power, bridges and marine structures in a sea area where the water depth is 25 meters and the seabed soil layer is about 30 meters. bed, and install a 3MW horizontal axis wind turbine on the partially buoyant ocean platform 10.

[0105] "Partially buoyant" offshore platforms have hollow buoyancy cylinders supported by the buoyancy of the water. The buoyancy of the buoyancy tube offsets the weight of some marine structures, and the buoyancy of the water bears about half the weight of the marine structures, which can reduce the rigidity of the supporting structure of the offshore platform, making its basic vibration frequency avoid the peak frequency of the earthquake, thereby improving the distance between the platform foundation and the foundation. insulation.

[0106] When an earthquake...

Embodiment 2

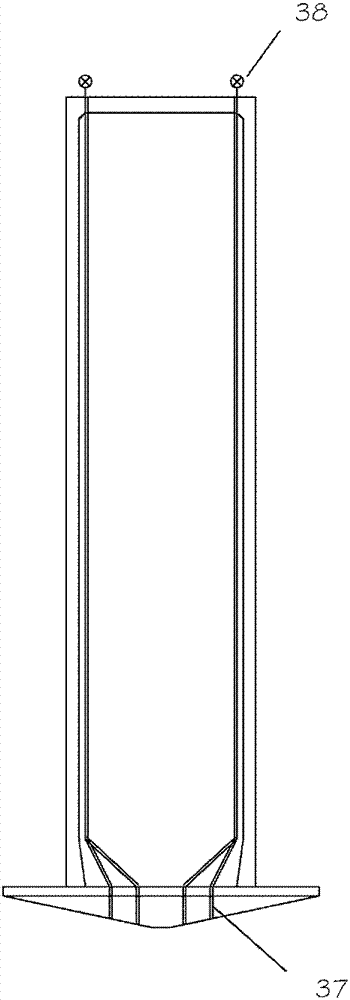

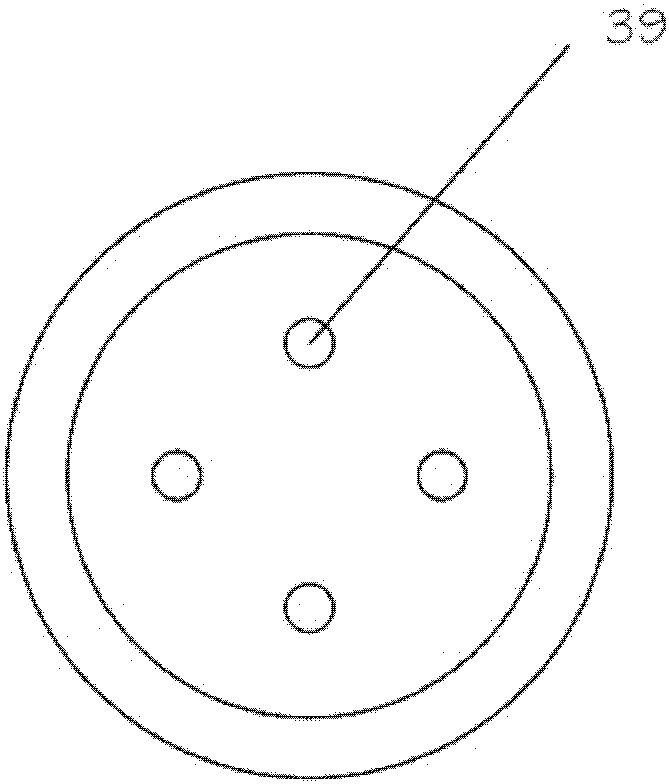

[0120] Bridges can also be supported on the partially buoyant ocean platform 10 . like Figure 12 as shown, Figure 12 Shown is the use of two buoyancy tubes connected under a cap to form the foundation of the pier. Figure 12 Only two buoyancy tubes 1 supporting the bridge are shown. Of course, three or six buoyancy cylinders 1 can also be symmetrically arranged. Multiple buoyancy cylinders 1 are jointly supported with caps, and bridge piers 35 are supported on the caps, and pier beams 36 are arranged on bridge piers 35. The buoyancy cylinders 1 have a diameter of 8 meters, a height of 30 meters, and a wall thickness of 0.4 meters. The water depth is 30 meters, and the soil layer is about 25 meters thick. The buoyancy cylinder 1 is fixed and embedded in the seabed bedrock 40 or the force-bearing layer 14 through the small-caliber bored pile 21, which is similar to that of the first embodiment.

Embodiment 3

[0122] Marine structures can also be supported on the partially buoyant marine platform 10 . like Figure 13 As shown, the partially buoyant ocean platform 10 is a grid structure, and the buoyancy cylinders 1 are respectively arranged on grid points of the grid; marine structures are supported on the partially buoyant ocean platform 10 . The partially buoyant ocean platform 10 is connected to the building structure secondary beam 33 through the lower building structure connecting beam 34 and the upper building structure main beam 32 . It can also be that multiple partially buoyant ocean platforms 10 form a multi-platform system by connecting beams, for example, as Figure 14 As shown, three sixteen buoyancy cylinder partial buoyancy ocean platforms 10 form a multi-platform system through connecting beams, and the multi-platform system can support marine buildings.

[0123] Prestressed concrete partial buoyancy ocean platform 10 supporting marine building structures or underw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com