Fill slope frame micro-tensioning supporting anchor plate supporting structure and construction method thereof

A technology of supporting structure and anchor plate, applied in basic structure engineering, excavation, sheet pile wall, etc., can solve the problems of increasing engineering cost, threatening people's life safety, immeasurable economic loss, etc., and achieve important social and economic benefits, The effect of avoiding the waste of land resources and strengthening the practical value of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

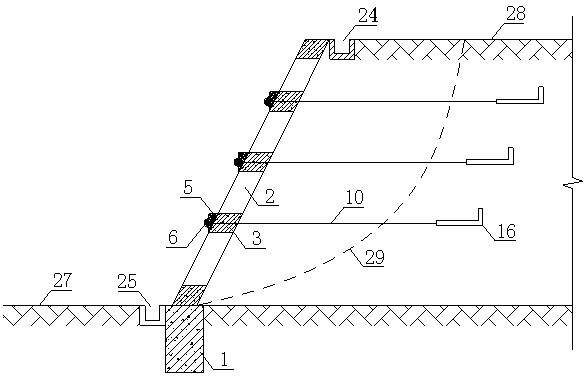

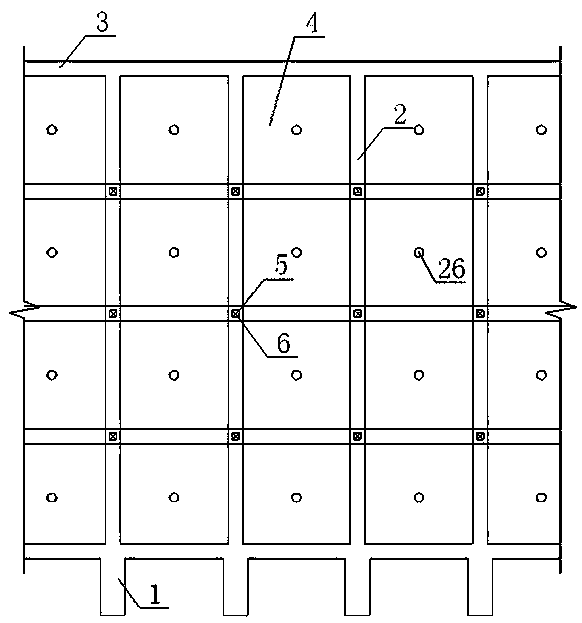

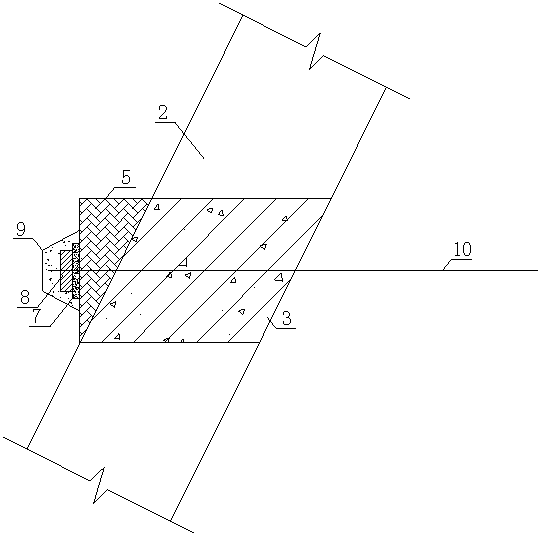

[0039] refer to Figure 1~Figure 6 , the embodiment of the present invention provides a micro-tensioned anchor plate support structure for a fill slope frame, which specifically includes a frame body arranged along the fill slope, which is arranged inside the fill soil body, in the height direction Several supporting anchor plates 16 arranged horizontally in layers and several steel strand stay cables 10 connecting the supporting anchor plates 16 and the frame body. In practical applications, the steel strand cables 10 are arranged horizontally, and the supporting anchor plate 16 is located in the stable soil inside the sliding surface 29 to ensure that the steel strand cables 10 form a stable and sufficient tension on the frame body.

[0040] The above-mentioned frame body specifically includes a soil retaining panel 4 arranged along the fill slope, crossbeams 3 and columns 2 arranged staggeredly on the soil retaining panel 4, and connected to the bottom of the column 2 below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com