Two-ring grouted single pile foundation

A single pile foundation and core filling technology, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of increasing foundation load, increasing steel consumption of single pile, increasing horizontal bearing capacity and deformation stiffness of pile foundation, etc. Achieve the effects of reducing the diameter of the outer ring, increasing the rigidity of the foundation, and reducing the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

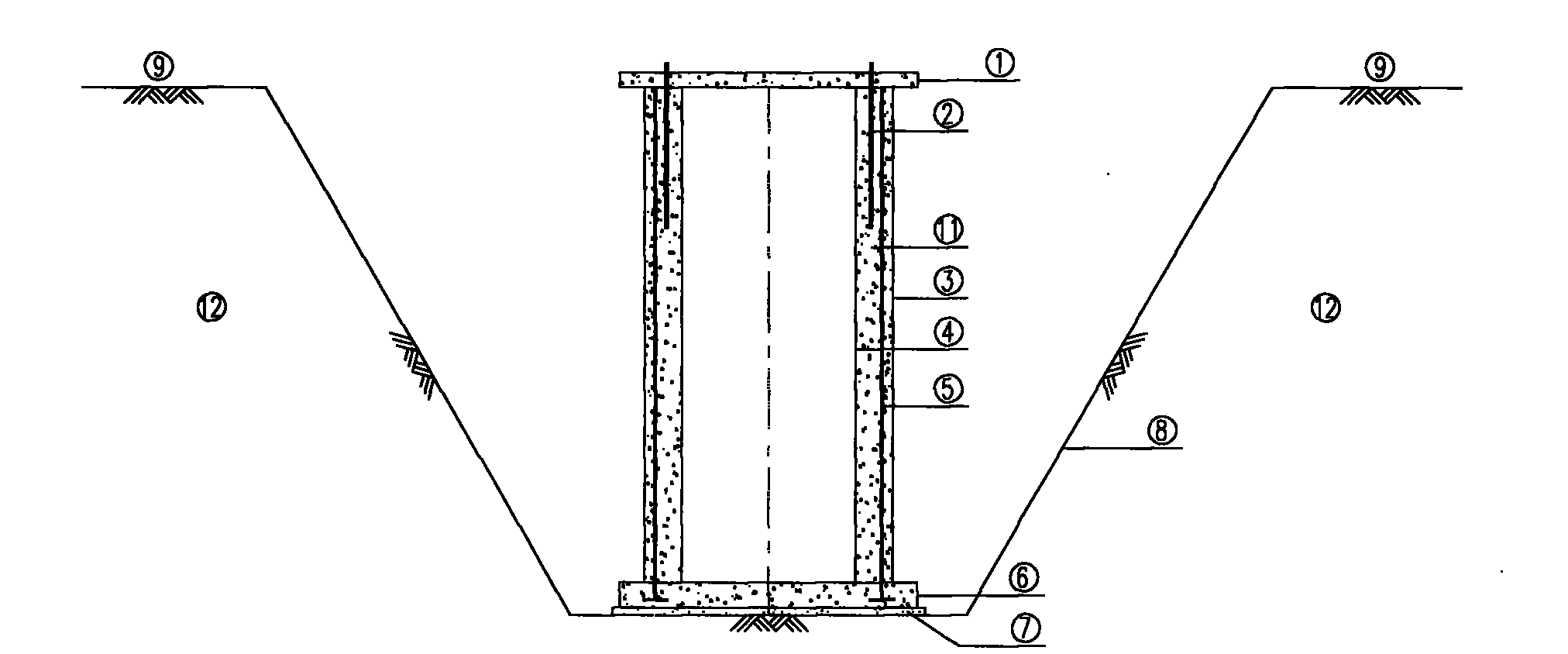

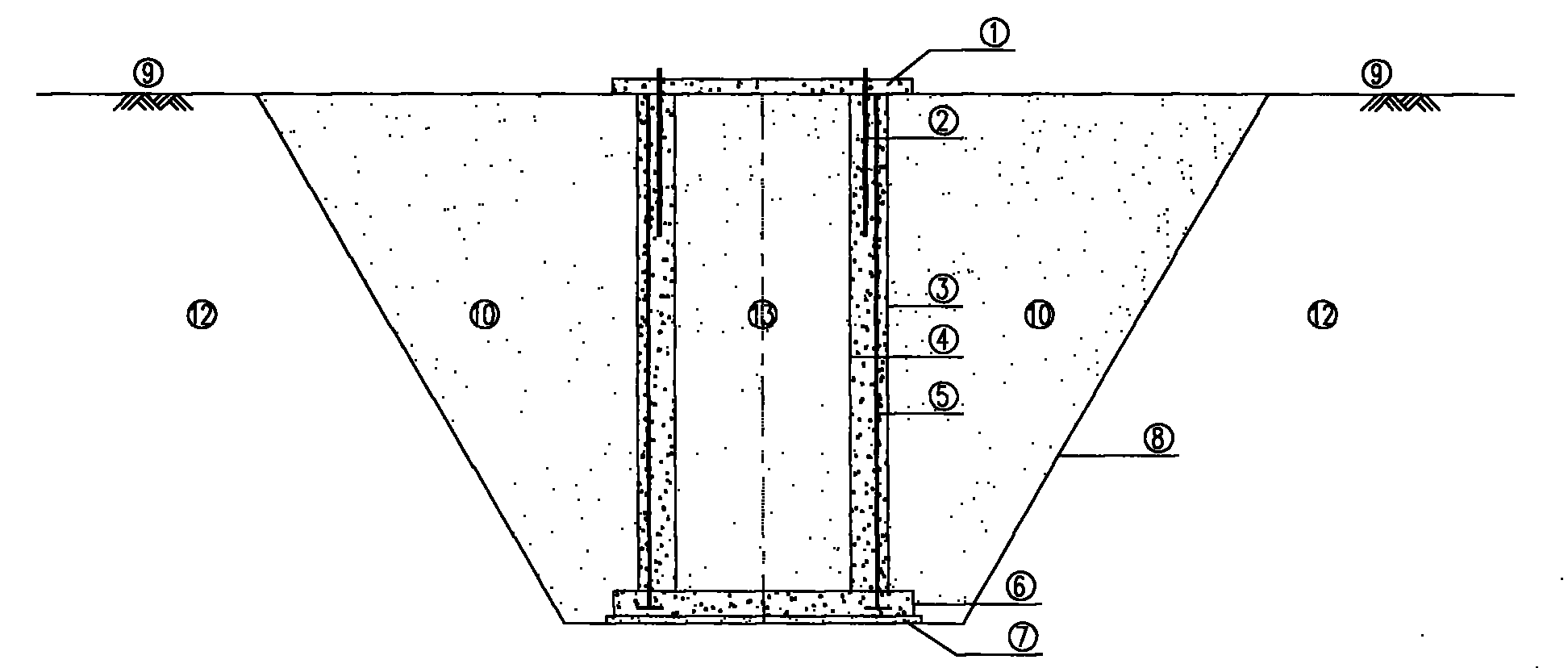

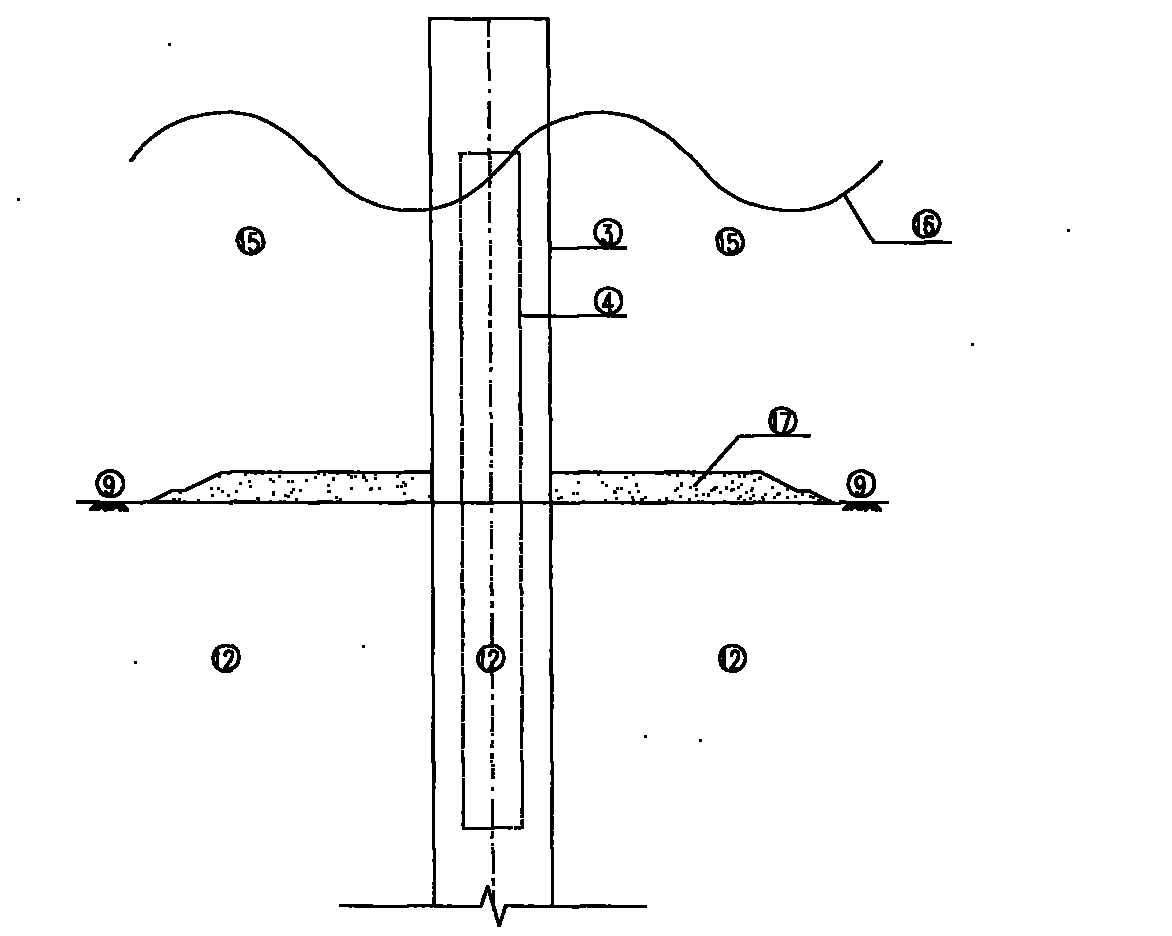

[0028] Embodiment 1 is a double-ring single-pile foundation suitable for land environments, as shown in Figures 1 and 2.

[0029] 1) Before the foundation construction, according to the soil layer distribution and soil properties of the site, adopt the slope excavation method, with a slope ratio of 1:0.6, and excavate to the bottom elevation of the foundation to form an excavation surface ⑧, as shown in Figure 1, requiring excavation The spoil shall be transported to a location away from the foundation for stacking;

[0030] 2) Construct the bottom cushion of the single pile, as shown in Figure 1 ⑦, and then use wooden formwork to set up the formwork, and bind the bottom plate reinforcement. Pouring concrete to form the bottom plate ⑥;

[0031] 3) Bind the reinforcement mesh ⑤ of the single-pile foundation. The reinforcement mesh is formed by binding the longitudinal reinforcement and the hoop reinforcement, and then the reinforcement mesh is lifted by a crane and placed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com