Novel by-stage construction carbon fiber confined concrete laminated column

A technology for confining concrete and carbon fiber, applied in the direction of columns, piers, pillars, etc., can solve the problem that the superiority of superimposed secondary force cannot be exerted, the bearing capacity and ductility of components, energy dissipation capacity, and the inability to effectively constrain core concrete, etc. problem, to achieve the effect of simple structure, improved seismic performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred examples of the present invention will be described below with reference to the accompanying drawings.

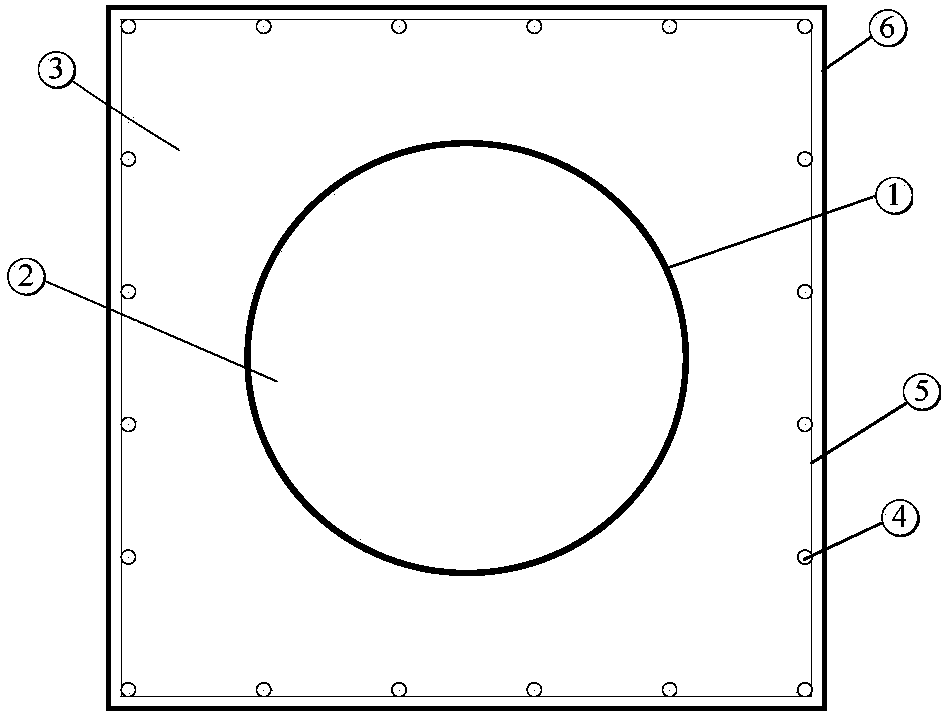

[0026] see figure 1 As shown, the embodiment of the present invention provides a carbon fiber-confined concrete composite column, and the carbon fiber-confined concrete composite column includes: internal carbon fiber cloth (1), core concrete (2), peripheral concrete (3), longitudinal reinforcement ( 4), stirrups (5) and outer carbon fiber cloth (6) in the bottom area.

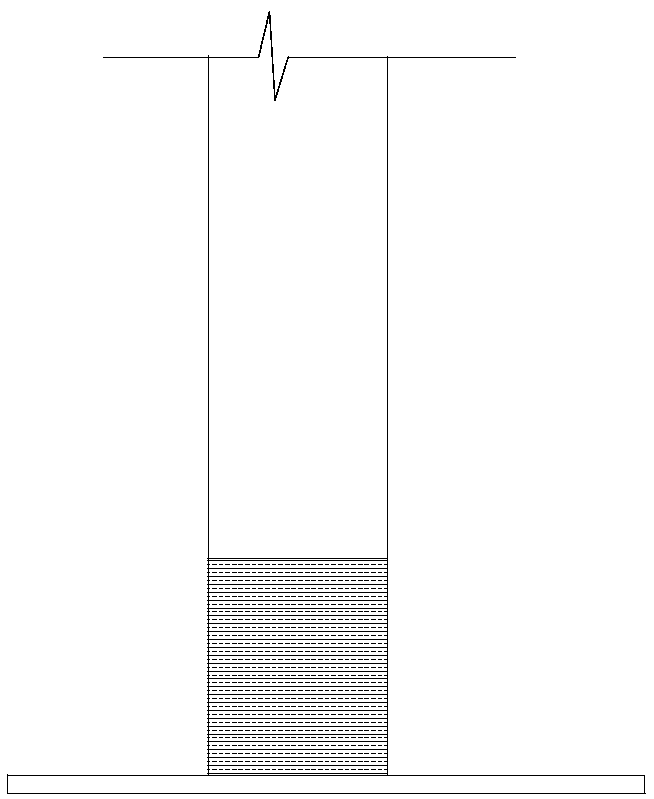

[0027] The outer cladding of the core carbon fiber confined concrete column composed of (1), (2) is provided with the reinforced concrete part composed of (3), (4), (5), and the (3), (4), (5 ) The bottom area of the reinforced concrete part composed of a certain height of carbon fiber cloth is set to form a restraint effect on the plastic hinge area.

[0028] Preferably, the cross-section of the core carbon fiber-confined concrete column is circular.

[0029] Preferably, the cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com