Soil non-excavation grounding resistance reduction method

A non-excavation, soil technology, applied in the direction of connection, connection contact materials, electrical components, etc., can solve the problems of high design calculation value, shortening the life of the grounding body, and unsatisfactory, and achieve low overall cost, short construction period, Obvious effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

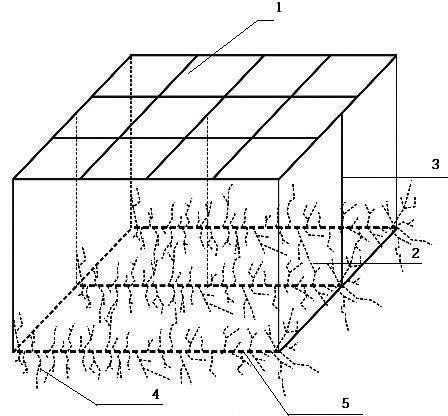

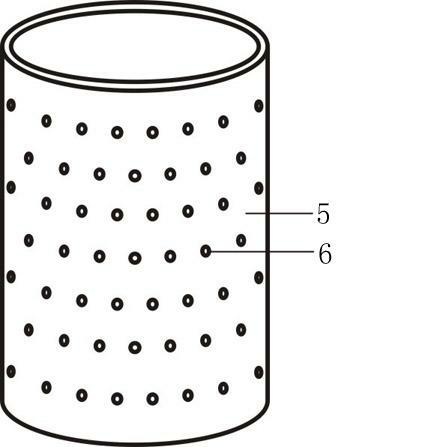

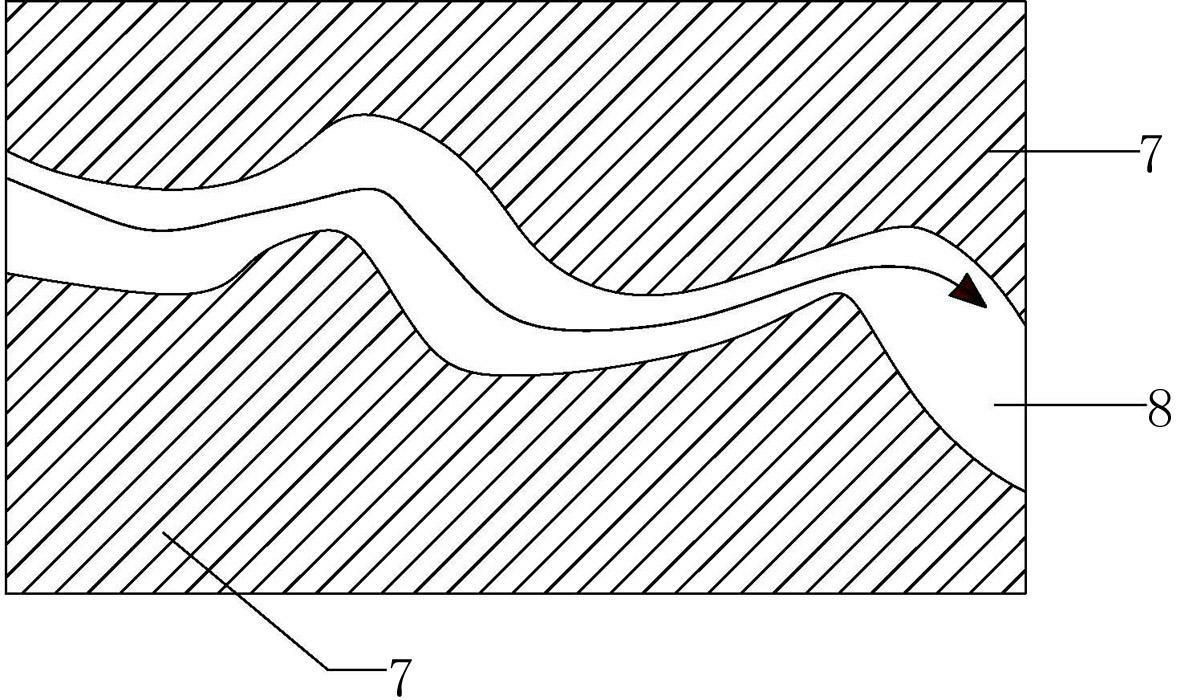

[0015] Example 1: In mountainous areas where the soil types are gravel, gravel, pure stone, rock, limestone, weathered soil rock, sedimentary rock, etc., the soil texture is poor, the soil distribution is uneven, and the soil resistivity is above 300Ω. When installing electrical facilities, first analyze the geological survey report, and use the numerical simulation method to analyze the spatial distribution of soil resistivity in underground layers, obtain the distribution layer 8 with soil resistivity less than 300Ω.m, and determine the longitude, latitude and depth of the inflection point of the distribution layer The three-dimensional coordinates are then set on the control panel of the traction drilling rig according to the three-dimensional coordinates of the longitude, latitude and depth of the inflection point of the soil resistivity distribution layer, and the traction drilling path 8 is set; the traction drill bit pulls the hollow synthetic material pipeline 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com