Manufacturing method of integrated inductor and integrated inductor obtained by using this method

A manufacturing method and inductor technology, applied in the field of inductors, can solve the problems of easy saturation noise, damage to internal materials in molding, damage to molds, etc., and achieve the effects of reasonable pressure selection, improved uniformity, and guaranteed formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

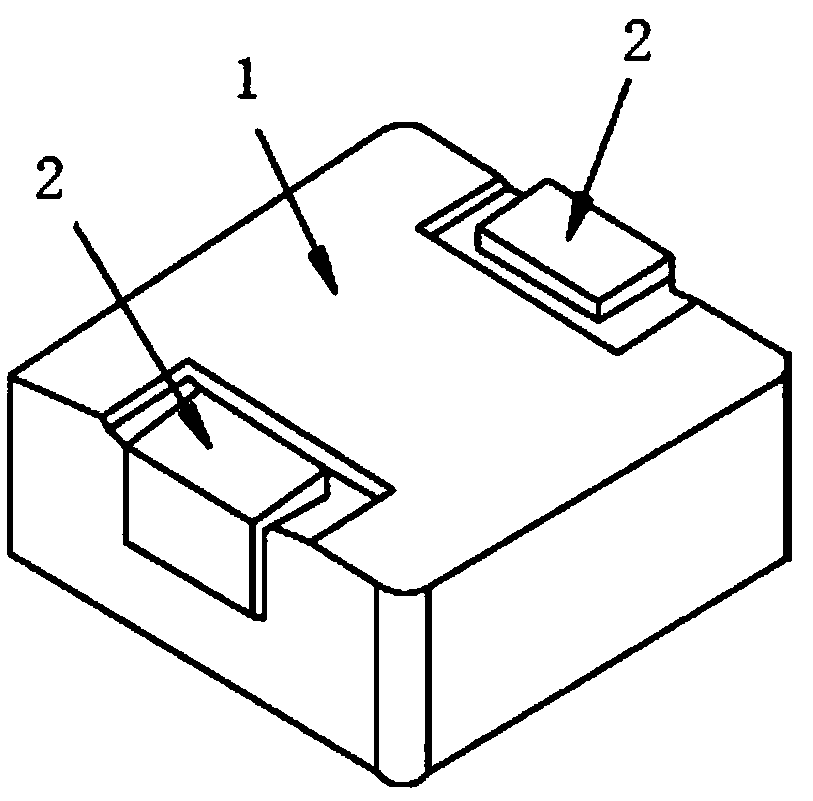

[0028] see figure 1 , an integrated inductor, comprising an inductance body 1, a coil embedded in the inductance body 1, a wire copper frame, and a wire terminal 2, and the wire terminal 2 is connected to the coil.

[0029] The manufacturing method of the above-mentioned integrated inductor includes the following steps:

[0030] Step A, making the iron core annular object, specifically: solidifying and sintering the mixed powder to obtain the iron core annular object, wherein: the mixed powder includes the following raw materials in parts by mass: 55.46 parts of carbonyl iron powder , 34.2 parts of reduced powder, 2.96 parts of magnesium oxide powder, 0.036 part of copper oxide powder, 0.65 part of stone powder and 6.20 parts of iron-based alloy; ) at a temperature of 850°C for 5.2 hours;

[0031] Step B, put the iron core annular object obtained in step A into a polishing machine for grinding, and obtain powder particles with a particle size of no more than 200 mesh, wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com